Solder resisting plug hole air guiding plate and manufacturing method therefor

A technology of air guide plate and plug hole, which is applied in the direction of manufacturing tools, printed circuit manufacturing, electrical components, etc., can solve the problems of high production cost of air guide plate and increase of overall operating cost, etc., achieve good support effect, and simple and fast processing method , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Preferred embodiments of the present invention will be described in detail below.

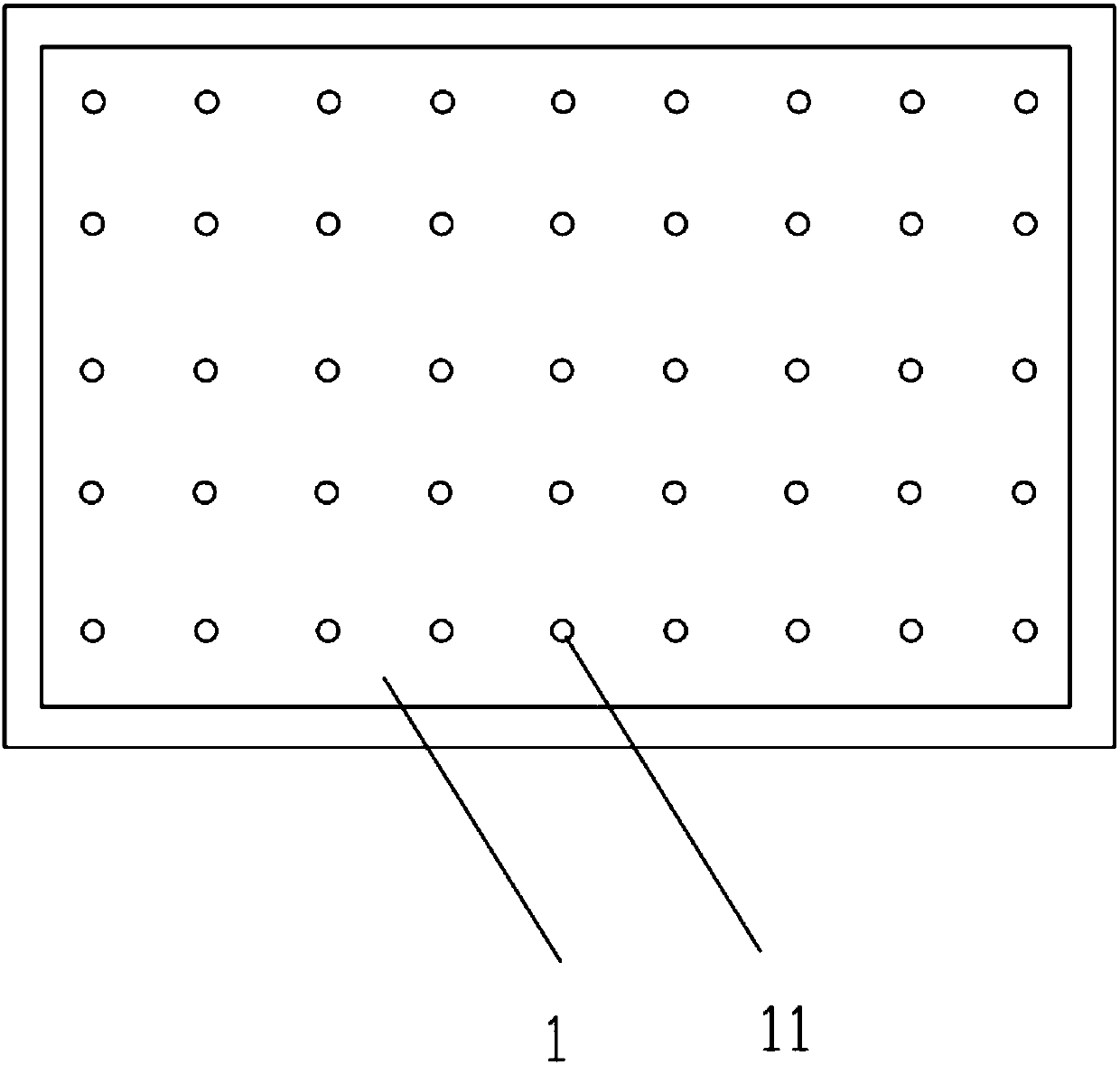

[0019] The base plate is made of epoxy resin glass fiber board with Rockwell hardness ≥ 115. The base plate is dotted with blind gongs in a matrix, and the flat-topped cone columns that match the air guide requirements of printed board printing are formed as residues to obtain the air guide plate.

[0020] The preparation of the substrate, according to the thickness and hardness requirements, is designed to use multiple 7628 series prepregs of epoxy glass fiber and release film, which are pressed under high temperature and high pressure under vacuum conditions. It is characterized in that an overall substrate with an overall thickness of 3.0-3.2 mm, high uniformity and high hardness is obtained.

[0021] After cutting the overall substrate to a size of 620mm in length and 530mm in width, the step of setting the depth of blind gongs on the substrate includes the air guiding fulcrum with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com