Bipolar lead-acid battery

A lead-acid battery, bipolar technology, applied in battery pack components, electrode carriers/current collectors, circuits, etc., can solve problems such as inability to charge and discharge large currents, inability to obtain safety guarantees, and difficult manufacturing processes , to achieve the effect of simple structure, high reliability and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

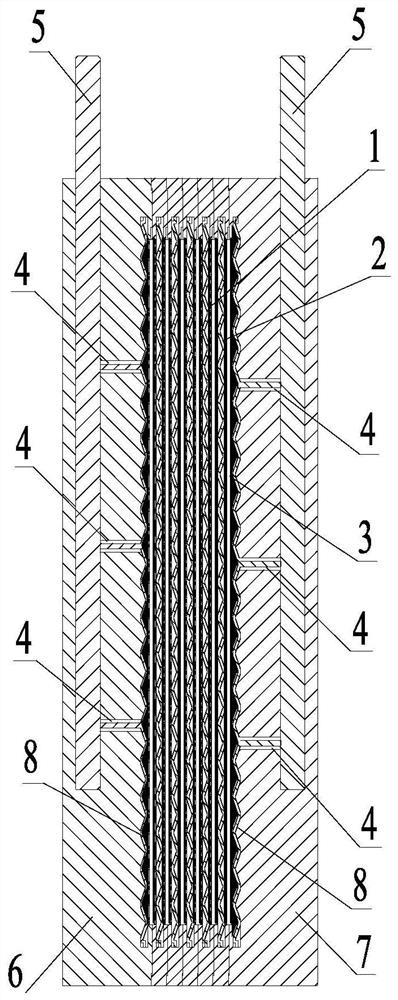

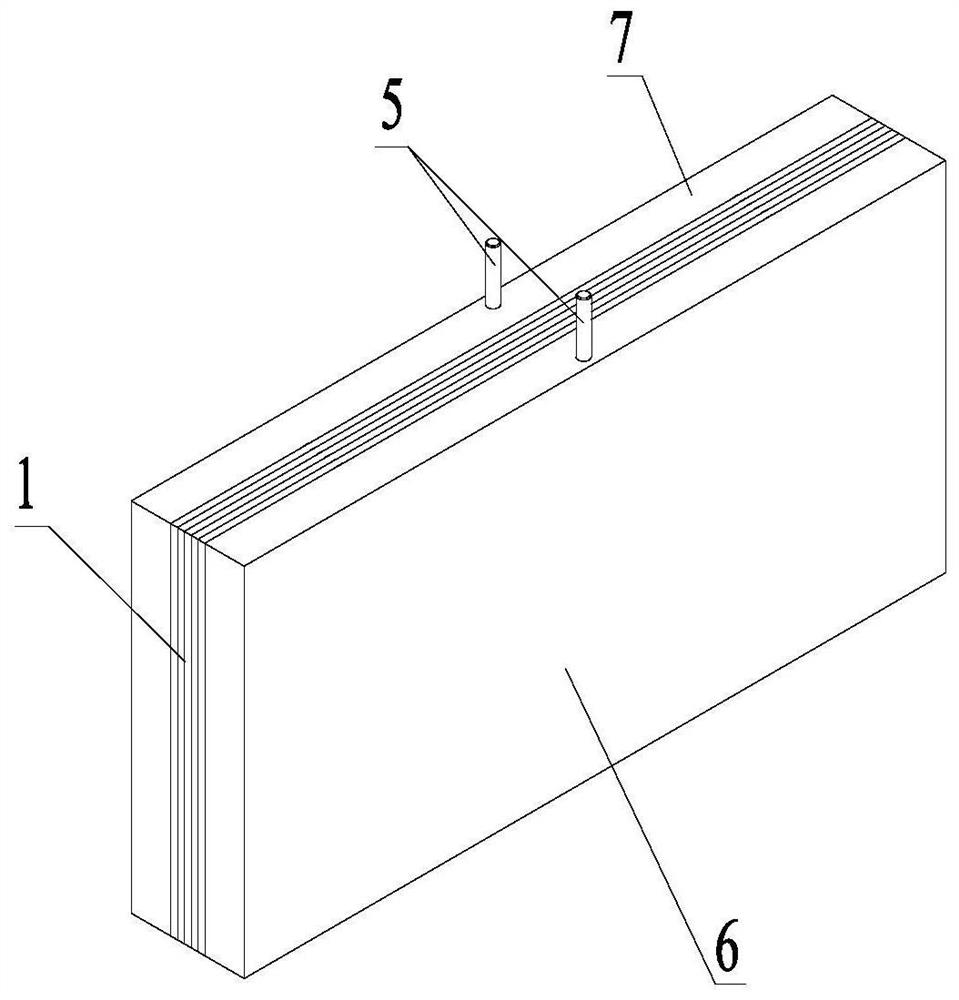

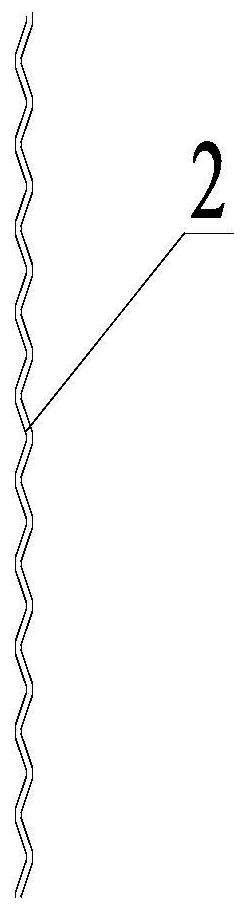

[0020] Such as figure 1 and figure 2 As shown, the bipolar lead-acid storage battery of the present invention comprises a positive side pole plate 6, a negative side pole plate 7 and a bipolar side grid 1 arranged between the positive side pole plate 6 and the negative side pole plate 7. The polar side grid 1 includes several pole plates 2 arranged side by side, and the pole plates 2 are lead strips, combined with image 3 As shown, the pole plate 2 is a corrugated pole plate 2 with a sinusoidal wave cross section formed by extrusion, and the two sides of the pole plate 2 are respectively coated with positive electrode paste and negative electrode paste and cured, and each two adjacent pole plates 2 There is a diaphragm 3 between them, the thickness of the diaphragm 3 is 1.2mm, the two sides of the diaphragm 3 are respectively in c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com