Marking and positioning apparatus for quality detection of twisted cables

A positioning device and stranded wire technology, which is applied to measurement devices, optical devices, optical testing of flaws/defects, etc., can solve the problems of low manual marking efficiency, damage to cable stranded wires, inaccurate marking, etc. Utilization, avoid hard-hitting damage, mark the effect of precise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

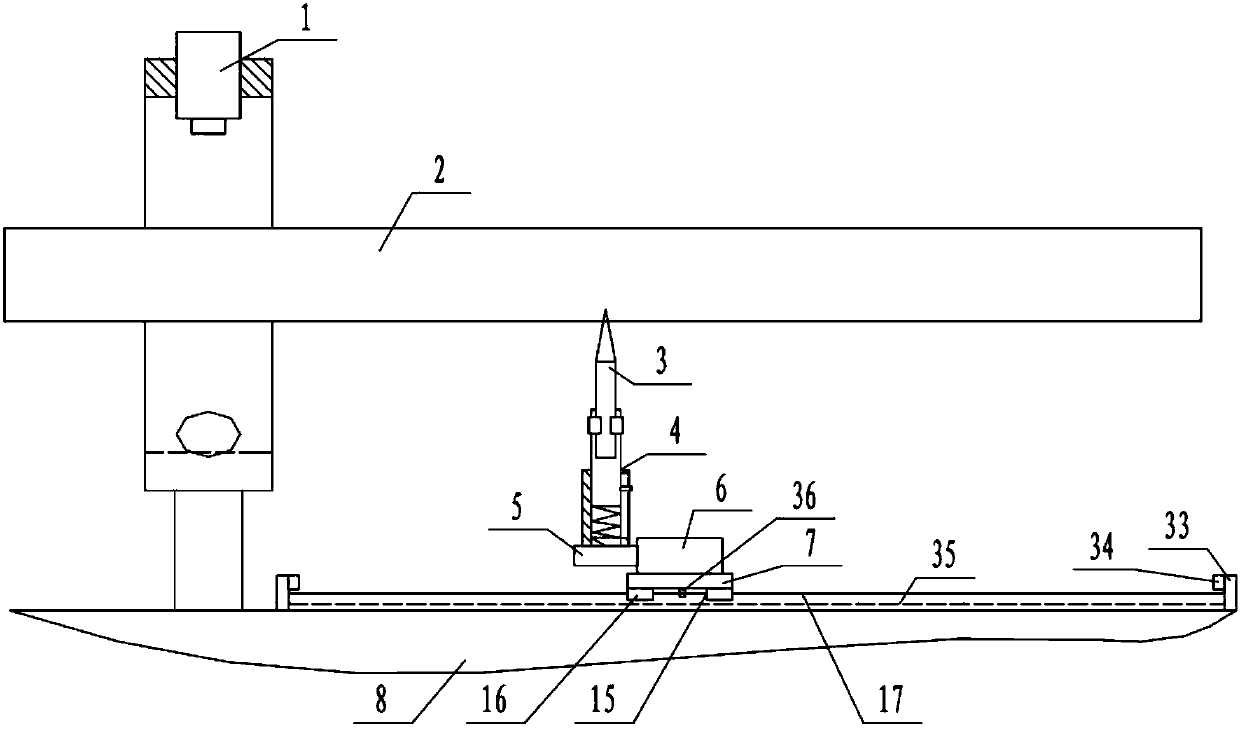

[0018] Embodiment 1: as Figure 1-Figure 7 As shown in the figure, a marking positioning device for quality inspection of cable twisted wires includes a paintbrush 3 connected to a telescopic rod 4, the tail end of the telescopic rod 4 is vertically connected to a swing shaft 5, and the swing shaft 5 is connected to a swing motor 6. The swing motor 6 is installed on the sliding seat 7, the sliding seat 7 is connected to the fixed table 8 through the slider guide rail pair 15, and the sliding seat 7 is also connected with a driving mechanism that drives the sliding seat 7 along the moving direction of the cable strand 2, The slide block guide rail pair 15 adopts two pairs of symmetrical installations, and the slide block 16 of the slide block guide rail pair 15 is fixedly connected on the lower side of the slide seat 1, and the guide rail 17 matched with the slide block is fixedly connected on the fixed table 8.

[0019] Preferably, the above-mentioned drive mechanism includes ...

Embodiment 2

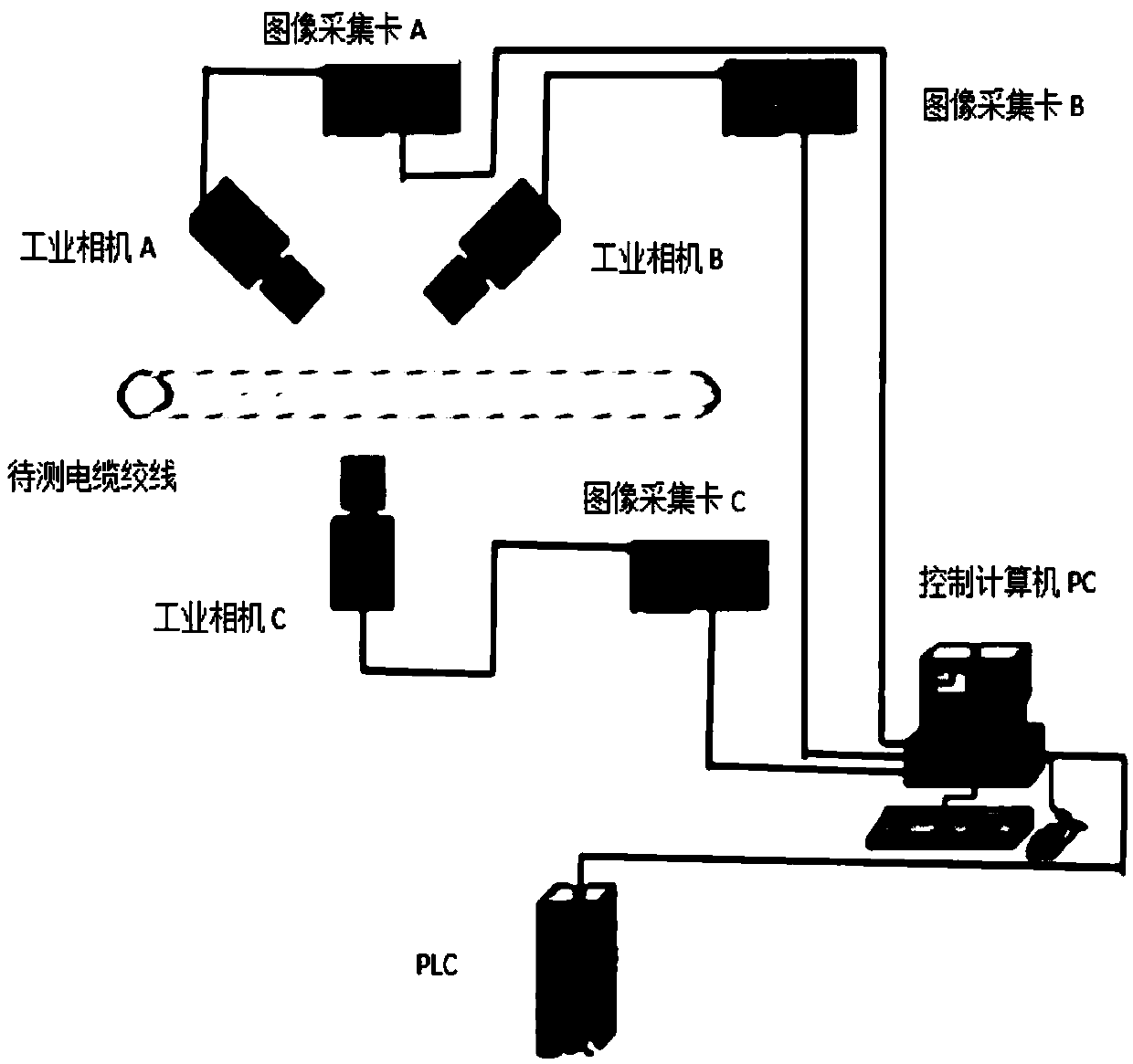

[0021] Embodiment 2: as Figure 1-Figure 7 As shown, the above mark positioning device is used in the cable strand quality inspection system, the system includes an image acquisition module, an image processing and identification module and a mark positioning module, the signal receiving end of the image processing and identification module is connected to the image acquisition module, and the control end is connected to The marking and positioning module, the image processing and identification module are used to process, identify and measure the collected images, the image acquisition module is used for online acquisition of cable strand images, and the marking and positioning module is used to locate and identify unqualified cable strands mark.

[0022] Preferably, the above-mentioned image processing and recognition module adopts a control computer PC.

[0023] Preferably, the above-mentioned image acquisition module includes an industrial camera 1 and an image acquisitio...

Embodiment 3

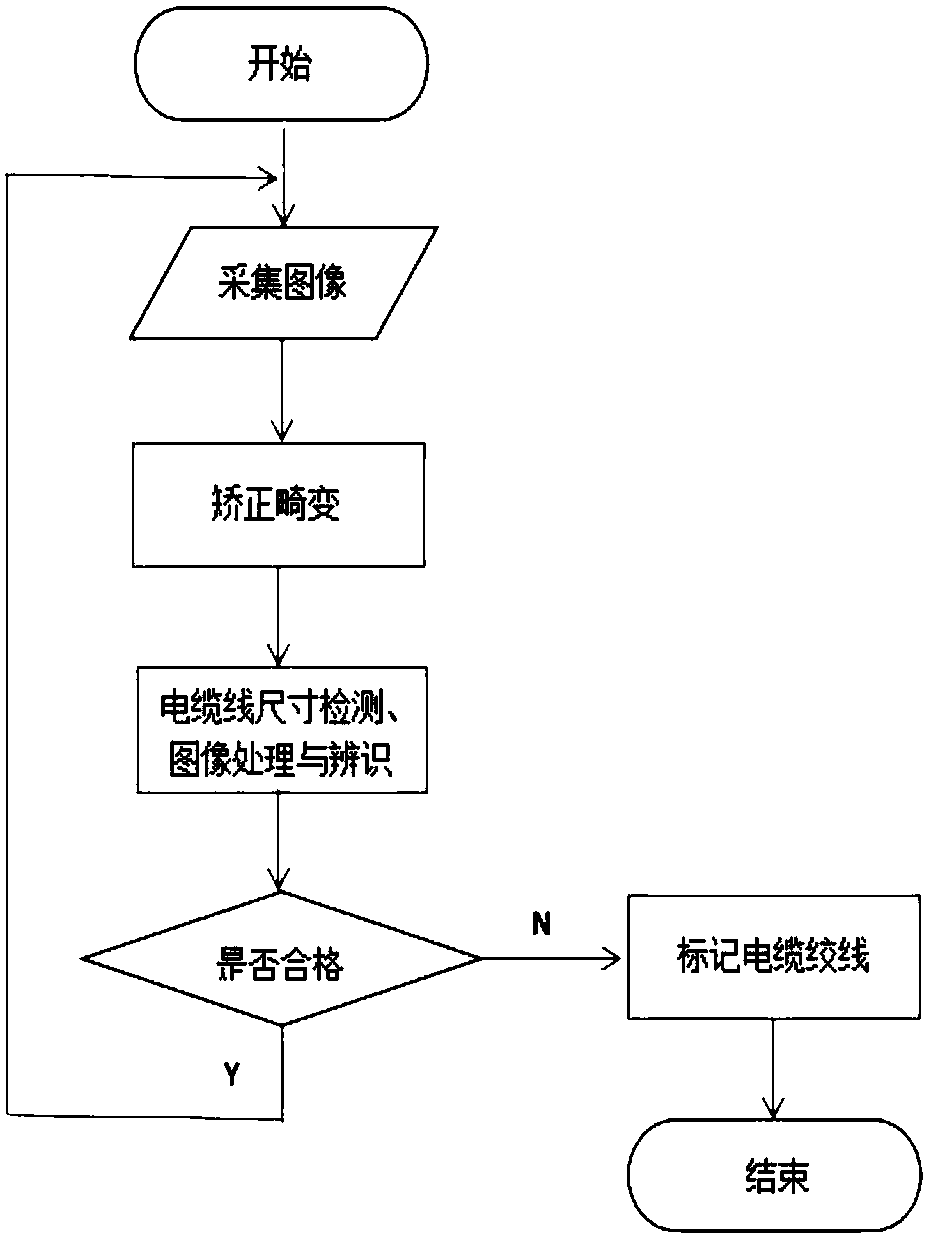

[0027] Embodiment 3: a detection method of a cable strand quality detection system, the method comprises the following steps:

[0028] (1) After the control computer is started and the system is running, the three industrial cameras in the image acquisition module collect the cable strand image online, and after each industrial camera collects a frame of image, it is immediately transmitted to the corresponding image acquisition card;

[0029] (2) The image acquisition card immediately transmits the received high-quality cable strand image to the image processing and identification module, that is, the control computer PC;

[0030] (3) Before identification, it is necessary to calibrate the industrial camera, that is, to correct the radial distortion of the camera. The qualified cable strands are collected through the image acquisition system, and the control computer PC processes the images of the qualified cable strands to obtain the radial distortion. Distortion correction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com