Method for manufacturing water convolvulus root-knot nematode giant cell paraffin sections

A technology of paraffin sectioning and water spinach, which is applied in the field of making paraffin sectioning of spinach root-knot giant cells, which can solve the problems of unseen giant-cell paraffin sectioning of water spinach root knots, and achieve the effects of improving sectioning efficiency, improving dyeing effect, and ensuring section quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for making paraffin sections of spinach root knot giant cells, comprising the following steps:

[0053] (1) Take materials

[0054] Cut the collected root knots into small sections of 0.5-1cm;

[0055] (2) vacuuming

[0056] According to the size of the material, it is equipped with syringe barrels of different sizes. First, lift the pump out, hold the syringe with your left hand and hold the needle socket with your index finger, then pour in the FAA fixative and materials, insert the syringe and turn the syringe upside down so that the needle socket is facing upwards, then remove the index finger and push the pump Insert until the fixative begins to emerge from the needle hole. At this time, there are only fixative and materials in the cylinder without other gaps. Finally, press the needle hole with your index finger, and pull out the cylinder with your right hand for 2-3 times in a row. is extracted;

[0057] (3) Fixed

[0058] Put the material into a fi...

Embodiment 2

[0090] A method for making paraffin slices of spinach root knot giant cells, the method of the present embodiment is the same as that of embodiment 1, except that in step (13), two slice angles are adopted: transverse cutting and longitudinal cutting, and the slice thickness is 10 μm.

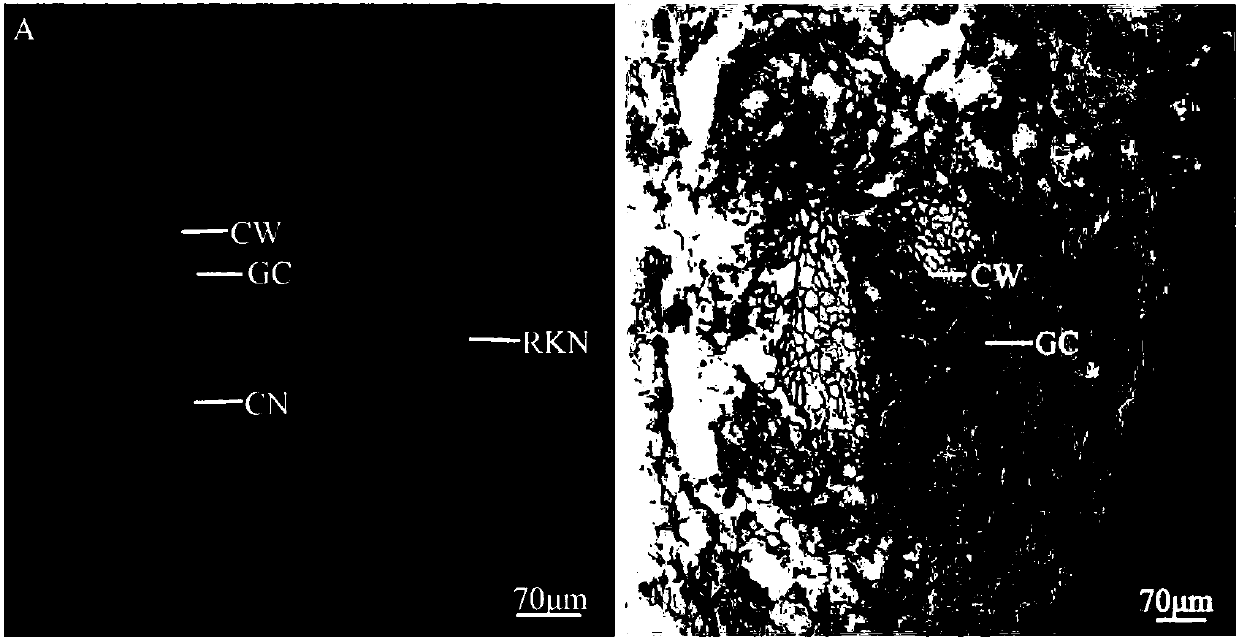

[0091] The results showed that the pear-shaped root-knot nematodes were present in the slices obtained by cross-sectioning the root-knot nematode and had a complete structure, and giant cells were distributed near the head of the root-knot nematode (see figure 2 -A); No piriform root-knot nematodes and giant cells appeared in the slice obtained by cutting the root knot longitudinally (see figure 2 -B). Therefore, the present invention finally uses a cross-section method to observe the histopathological structure of giant cells and root-knot nematodes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com