Integrated multifunctional ink transporting device for flexographic printing

A flexographic printing, multi-functional technology, applied in the general parts of printing machinery, printing, printing machines, etc., can solve the problems of low work efficiency, blockage, ink quality degradation, etc., to change waste and odor emission, prevent Damage to parts, effect of reducing volatilization area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

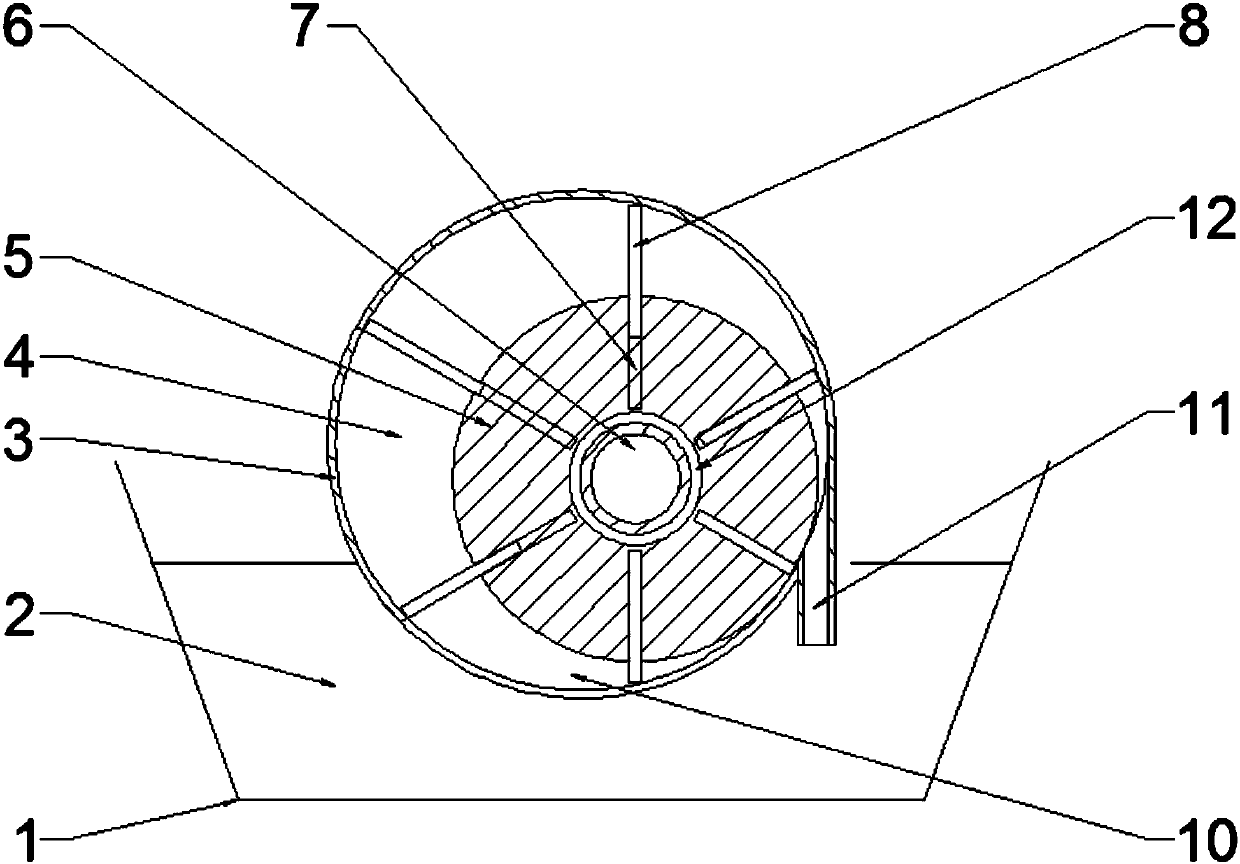

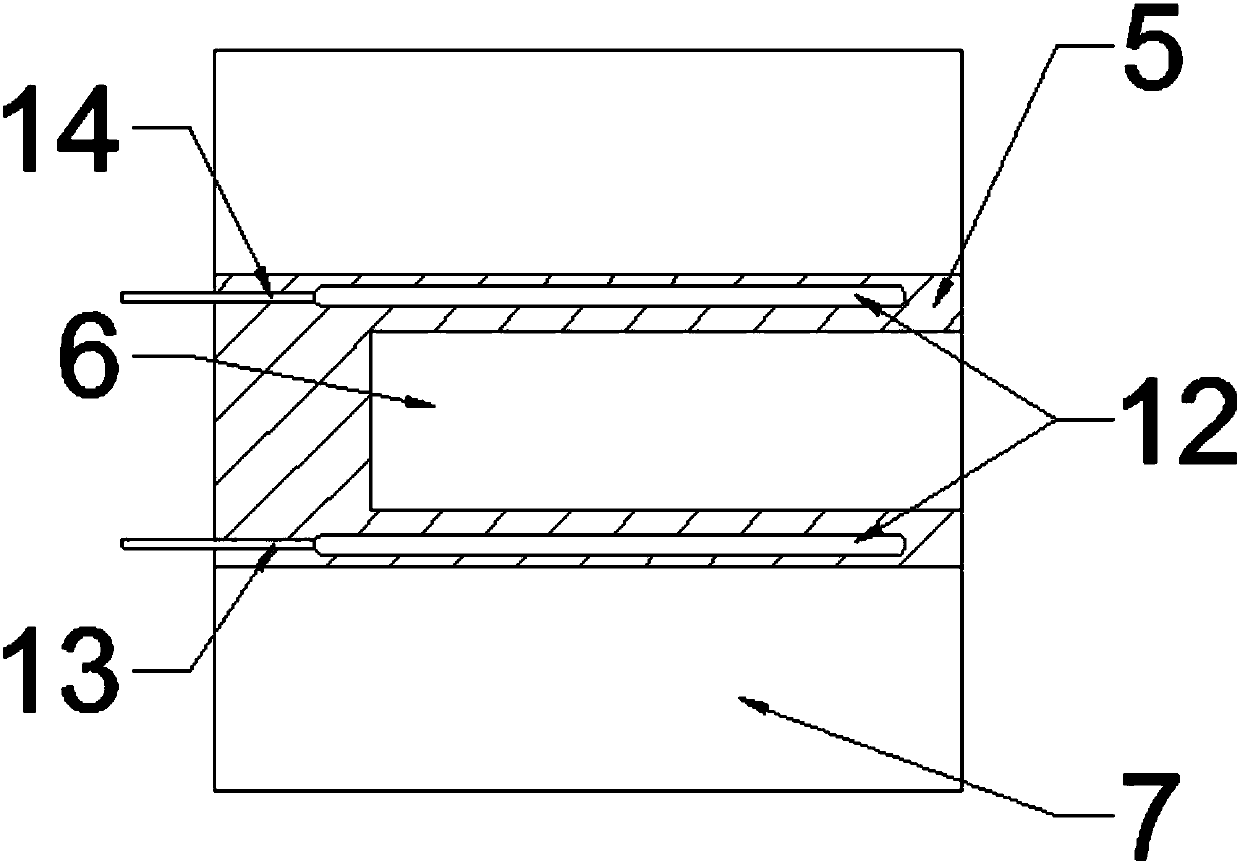

[0026] This embodiment combines figure 1 , figure 2 and image 3 As shown, the integrated multifunctional flexographic printing inking device includes an ink fountain 1, the ink fountain 1 is equipped with ink 2, and a cylindrical ink fountain roller, the ink fountain roller is partially immersed in the ink 2, and the ink fountain roller From the outside to the inside, it includes a casing 3, an ink flow chamber 4 and a rotatable hollow cylindrical rotor 5. The curved wall of the casing 3 is provided with a number of ink outlet holes 9 communicating with the ink flow chamber 4. The ink outlet The holes 9 are arranged in a row and evenly distributed on the curved wall of the casing 3;

[0027] The rotor 5 is inscribed on the inner wall of the housing 3 obliquely below, and the rotor 5 is coaxially provided with a rotating shaft 6 and an annular cavity 12, the cavity 12 is arranged on the periphery of the rotating shaft 6, and the side of the cavity 12 The water inlet pipe 1...

Embodiment 2

[0039] This embodiment is further improved based on embodiment 1, as figure 1 As shown, the height of the soaked part of the ink fountain roller is higher than the maximum height of the ink inlet 10 and the ink return port 11 .

[0040] During use, the height of the soaked part of the ink fountain roller is higher than the maximum height of the ink inlet 10 and the ink return port 11, so that the ink fountain roller can absorb ink to the maximum every time, thereby improving efficiency, and the ink return is also directly in the ink fountain The ink of 1 is carried out under the liquid surface of 2 to prevent splashing and the distribution of ink mist.

Embodiment 3

[0042] This embodiment is further improved based on any one of Embodiments 1-2, such as figure 1 As shown, the rotating shaft 6 is connected with a variable frequency motor.

[0043] During use, the running speed of the rotating shaft 6 can be adjusted through the frequency conversion motor, thereby adjusting the ink output speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com