Directly connected drainpipe floor drain and its installation method

A technology for drainage pipes and floor drains, applied in water supply devices, drainage structures, waterway systems, etc., can solve problems such as floor seepage, achieve the effects of speeding up construction progress, avoiding openings, and reducing construction procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

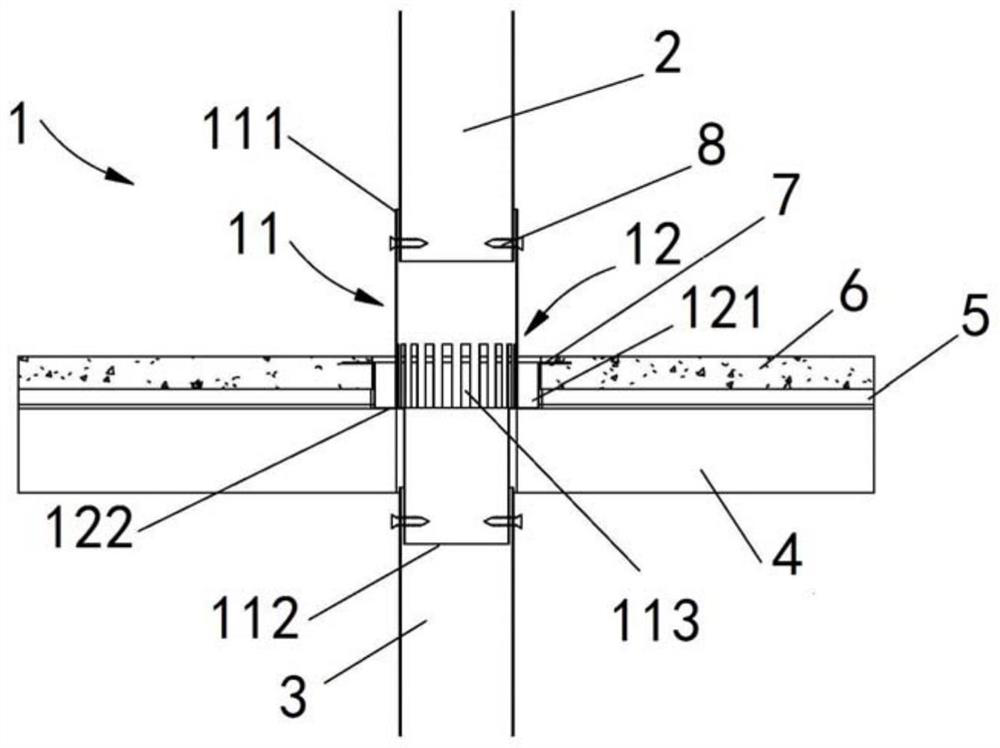

[0029] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings.

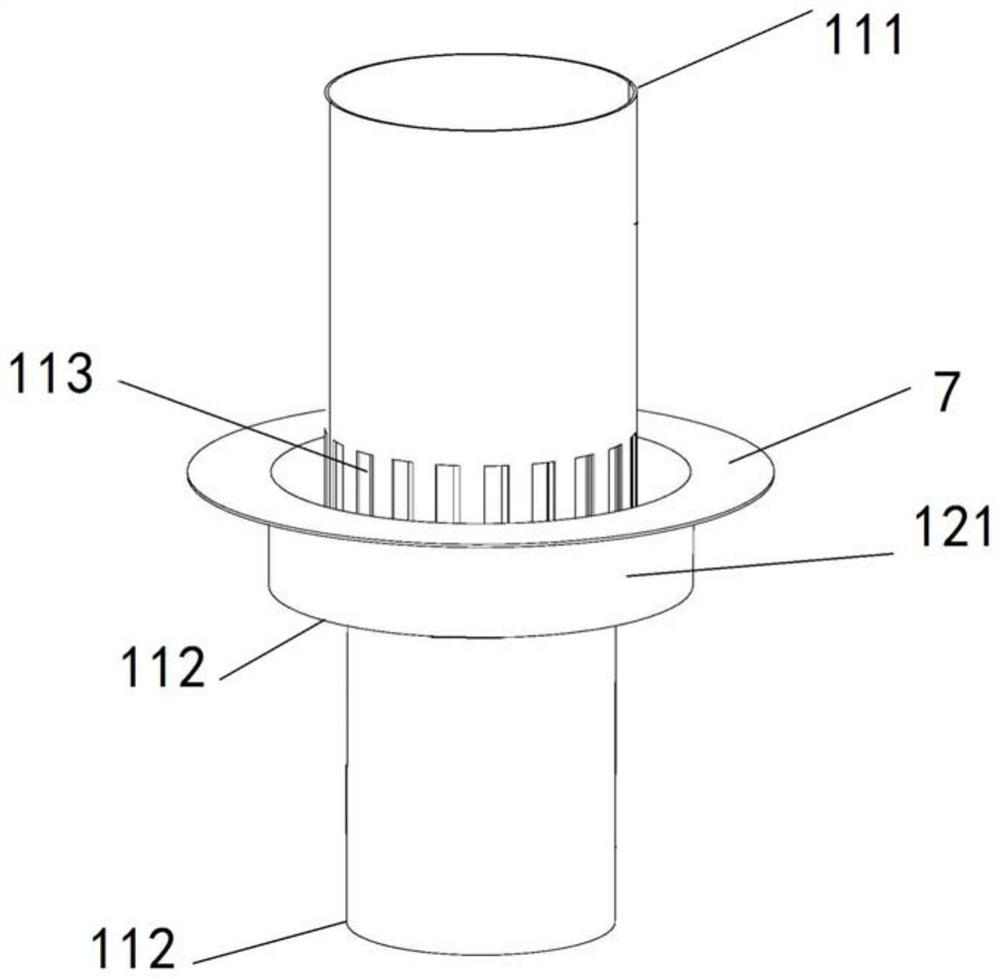

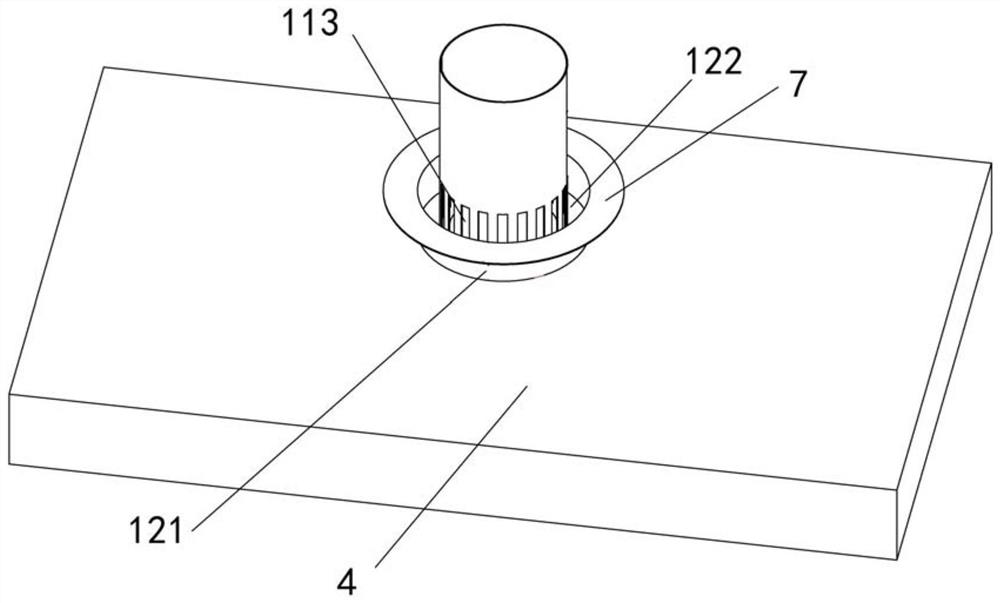

[0030] see figure 1 , figure 2 As shown, the present invention provides a floor drain directly connected to the drain pipe. The floor drain 1 is placed in the reserved drain pipe hole of the floor structure and connected to the upper drain pipe 2 located on the upper side of the floor structure and the drain pipe located on the floor structure. The lower drainpipe 3 on the lower side, the floor drain includes a body 11 and a supporting structure 12 .

[0031] The body 11 is shaped like a cylinder and has an upper port 111 and a lower port 112, the upper port 111 is connected to the upper drain pipe 2, and the lower port 112 is connected to the lower drain pipe 3. ; The middle surface of the body 11 is provided with a leaking gate 113 extending axially along its cylindrical shape.

[0032] In the embodiment of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com