Reactive dyeing method for figured sea-island super-fine fiber suede leather and hair

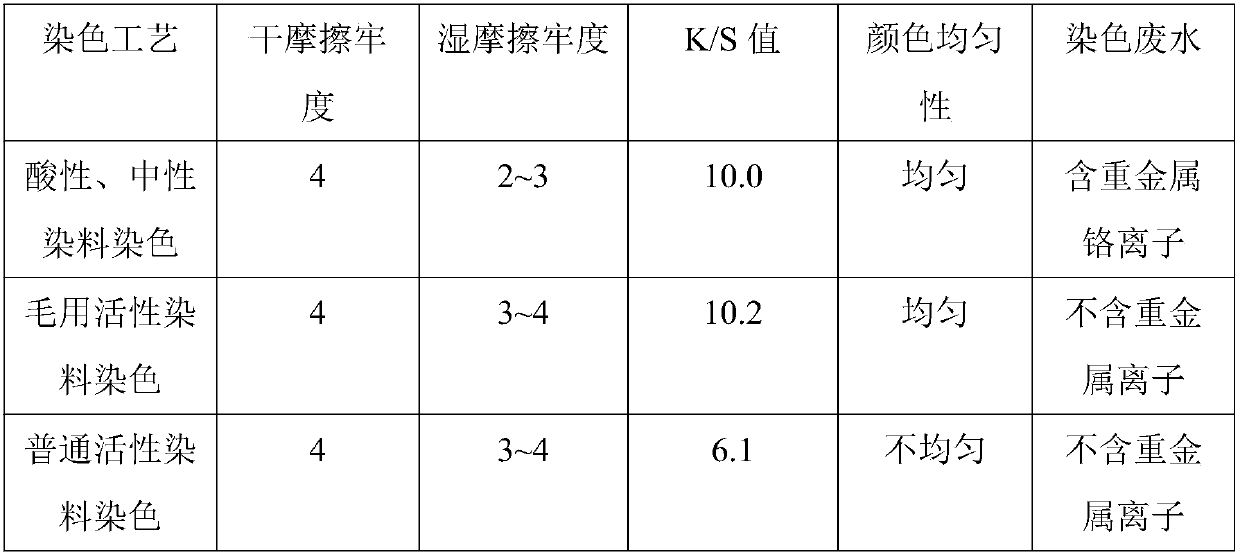

A technology of reactive dyes and microfibers for wool, which can be used in dyeing, textiles, and papermaking. It can solve the problems of poor color fastness and heavy metal pollution, and achieve the effect of low wet rubbing fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] (1) Put Dingshima microfiber suede and reactive dyes for wool in the dyeing bath, the bath ratio is 1:15, adjust the pH to 3 with acetic acid, raise the temperature from room temperature to 90 °C at a rate of 1 °C / min, and keep warm 10min, then lowered to 20°C at 1°C / min;

[0015] The weight of reactive dye A for wool is 2% of the fabric;

[0016] Described wool reactive dyestuff is selected from Huntsman wool reactive dyestuff, trade name is Lan Nasu (LANASOL);

[0017] (2) Use acetic acid to adjust the pH of the dyeing bath to 3, and fix the color at 20°C for 20 minutes to obtain dyed Dingshima microfiber suede.

Embodiment 2

[0019] (1) Put Dingshima microfiber suede and reactive dyes for wool in the dyeing bath, the bath ratio is 1:30, the pH is adjusted to 7 with acetic acid, the temperature is raised from room temperature to 120 °C at a rate of 2 °C / min, and the temperature is kept 70min, then lowered to 60°C at 3°C / min;

[0020] The weight of reactive dye A for wool is 5% of fabric;

[0021] (2) Use acetic acid to adjust the pH of the dyeing bath to 9, and fix the color at 70°C for 60 minutes to obtain dyed Dingshima microfiber suede.

Embodiment 3

[0023] (1) Put Dingshima microfiber suede and reactive dyes for wool in the dyeing bath, the bath ratio is 1:20, adjust the pH to 5 with acetic acid, raise the temperature from room temperature to 100 °C at a rate of 1.5 °C / min, and keep warm 40min, then lowered to 40°C at 2°C / min;

[0024] The weight of reactive dye A for wool is 3% of fabric;

[0025] (2) Use acetic acid to adjust the pH of the dyeing bath to 7, and fix the color at 40°C for 40 minutes to obtain dyed Dingshima microfiber suede.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com