Porous graphene-carbon nanotube composite fiber and its rapid preparation method

A carbon nanotube composite and porous graphene technology, which is applied in fiber processing, fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of high equipment requirements, complicated preparation process, long preparation cycle, etc., and achieve cost reduction and high process efficiency convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) Mix the graphene oxide dispersion with a concentration of about 5 mg / ml and the carbon nanotube SDS aqueous dispersion with a concentration of about 0.1 mg / ml at a volume ratio of 1:1, ultrasonicate, and stir for 0.5 h;

[0053] (2) The solution prepared in step (1) is injected into 25°C through a syringe with a spinneret inner diameter of about 200 μm, and the mass concentration is 5% CaCl 2 In the coagulation bath, obtain fibrous composite fibers, and soak the fibers in the coagulation bath for 30 minutes;

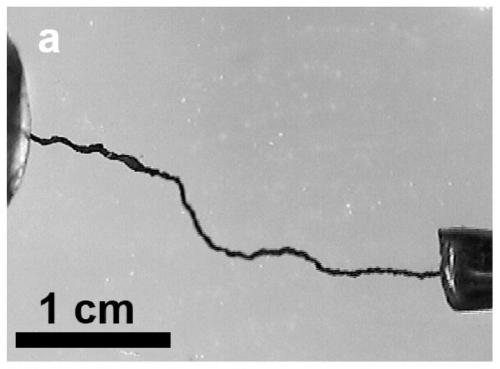

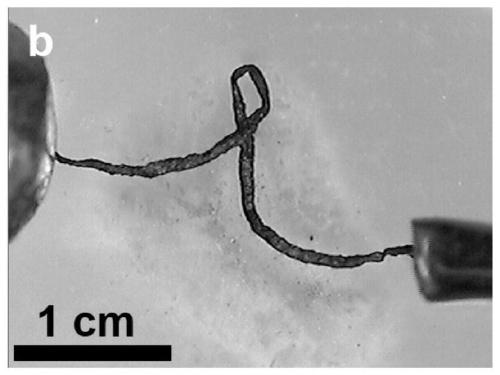

[0054] (3) the molded fiber obtained in step (2) (see Figure 1a , Figure 1c ) was transferred to 35% HI acid, and chemically reduced at 90°C for 6h, then washed with water for 3 times, and vacuum-dried at 25°C for 3h;

[0055] (4) The fiber obtained in step (3) is fixed on a glass slide, and in the air, a DC voltage of 10V / cm is applied to both ends of the fiber for 5 seconds to finally obtain the expanded porous graphene-carbon nanotube composite fiber (s...

Embodiment 2

[0057] (1) Mix 5mg / ml graphene oxide dispersion with 0.2mg / ml carbon nanotube SDS aqueous dispersion at a volume ratio of 1:1, ultrasonicate, and stir for 0.5h;

[0058] (2) The solution prepared in step (1) is injected into a syringe with a spinneret inner diameter of about 200 μm to 25° C., and the mass concentration is 5% CaCl 2 In the coagulation bath, obtain the fibrous composite fiber, and make the fiber soak in the coagulation bath for 30 minutes;

[0059] (3) Transfer the molded fiber obtained in step (2) to 35% HI acid, and perform chemical reduction at 90°C for 6h, then wash it with water for 3 times, and dry it in vacuum at 25°C for 3h;

[0060] (4) The fiber obtained in step (3) is fixed on a glass slide, and in the air, a DC voltage of 10V / cm is applied to both ends of the fiber for 5 seconds to finally obtain an expanded porous graphene-carbon nanotube composite fiber.

Embodiment 3

[0062] (1) Mix 5mg / ml graphene oxide dispersion with 0.2mg / ml carbon nanotube SDS aqueous dispersion at a volume ratio of 1:1, ultrasonicate, and stir for 0.5h;

[0063] (2) The solution prepared in step (1) is injected into a syringe with a spinneret inner diameter of about 200 μm to 25° C., and the mass concentration is 5% CaCl 2 In the coagulation bath, obtain the fibrous composite fiber, and make the fiber soak in the coagulation bath for 30 minutes;

[0064] (3) Transfer the molded fiber obtained in step (2) to 35% HI acid, and perform chemical reduction at 90°C for 6h, then wash it with water for 3 times, and dry it in vacuum at 25°C for 3h;

[0065] (4) Fix the fiber obtained in step (3) on a glass slide, and place it in an inert atmosphere, and apply a DC voltage of 15V / cm to both ends of the fiber for 5 seconds to finally obtain expanded porous graphene-carbon nanotube composite fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com