A kind of ultra-low water content carbon dioxide fracturing fluid and its preparation method

A carbon dioxide and fracturing fluid technology, applied in the field of fracturing fluid, can solve problems such as retention, affecting post-fracturing stimulation, fracturing fluid thickening and sand-carrying performance difficulties, etc., to increase viscosity, increase construction sand ratio, and thicken significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides an ultra-low water content carbon dioxide foam / carbon dioxide anhydrous fracturing fluid, which includes: 10% liquid water, 0.01% hydrophobic group polyacrylamide GRF-1H based on its total weight of 100%. , 40% gaseous carbon dioxide, and the balance liquid carbon dioxide.

[0032] The ultra-low water content carbon dioxide foam / carbon dioxide fracturing fluid of this embodiment can be prepared as follows:

[0033] At room temperature, the hydrophobic group polyacrylamide GRF-1H is uniformly dispersed in water according to the proportion, and after stirring for 15 minutes at a temperature of 25°C, the GRF-1H solution is left in a water bath at a temperature of 30°C for 4 hours;

[0034] Mix the dissolved GRF-1H solution with carbon dioxide gas to form carbon dioxide foam;

[0035] Mix with liquid carbon dioxide in high pressure pipeline in proportion to obtain ultra-low water content carbon dioxide foam / carbon dioxide fracturing fluid.

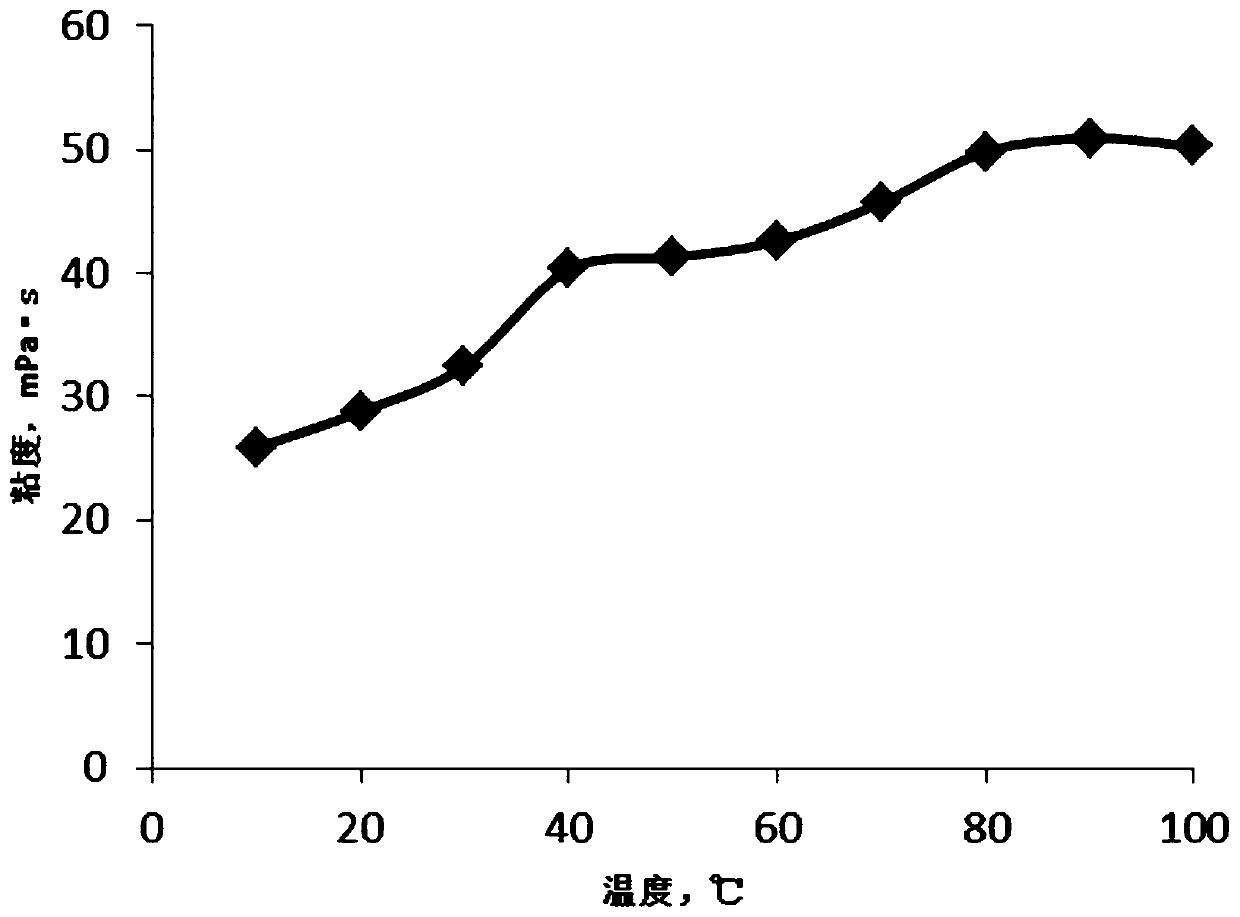

[0036...

Embodiment 2

[0039] This embodiment provides an ultra-low water content carbon dioxide foam / nitrogen fracturing fluid, which includes: 10% liquid water, 0.02% hydrophobic group polyacrylamide GRF-1H, 40% based on its total weight of 100%. % nitrogen, and the balance liquid carbon dioxide

[0040] The ultra-low water content carbon dioxide foam / nitrogen fracturing fluid of this embodiment can be prepared as follows:

[0041] At room temperature, the hydrophobic group polyacrylamide GRF-1H is uniformly dispersed in water according to the proportion, and after stirring for 15 minutes at a temperature of 25°C, the GRF-1H solution is left in a water bath at a temperature of 30°C for 4 hours;

[0042] Mix the dissolved GRF-1H solution with carbon dioxide gas to form a carbon dioxide foam system;

[0043] Mix with nitrogen in high pressure pipeline in proportion to obtain ultra-low water content carbon dioxide foam / nitrogen fracturing fluid.

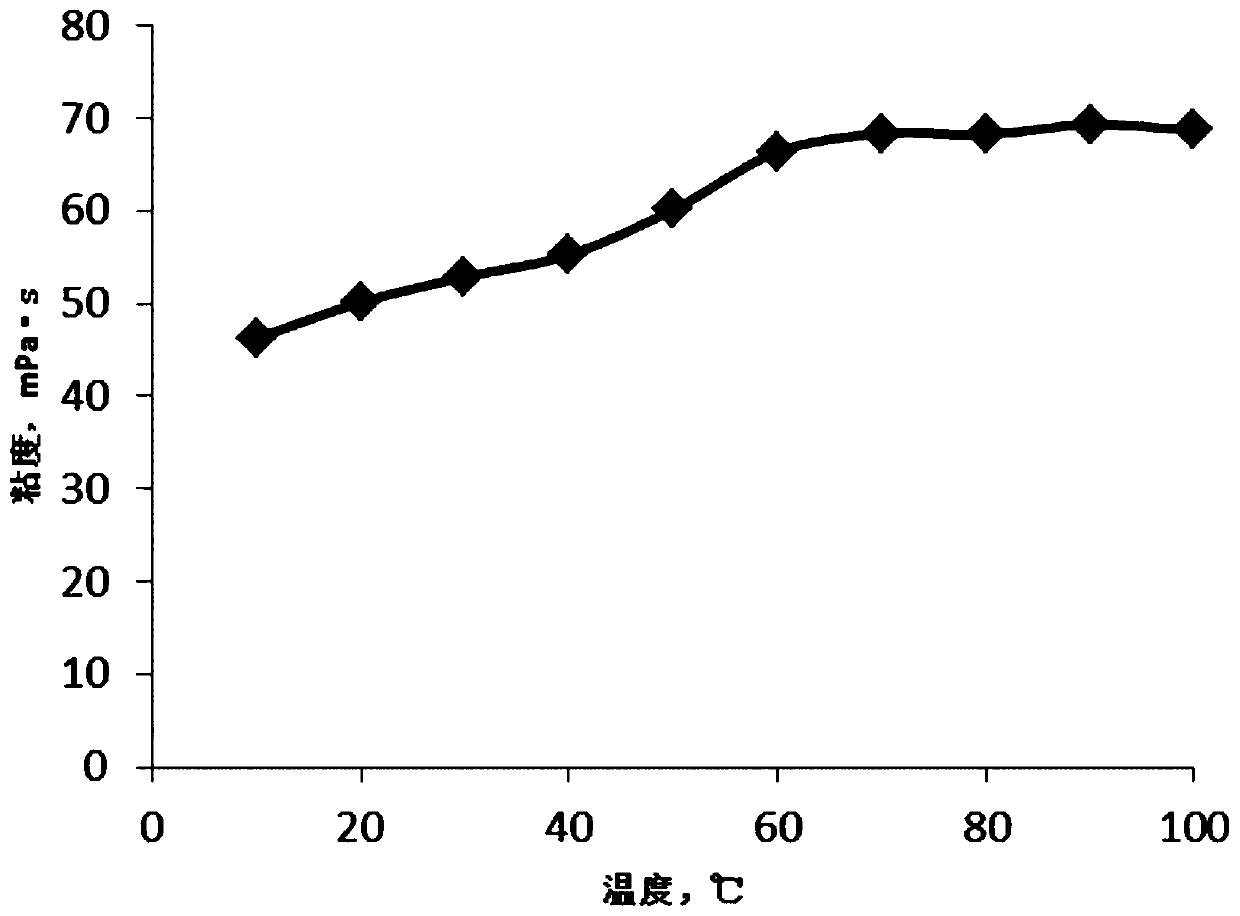

[0044] The fracturing performance test of the ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com