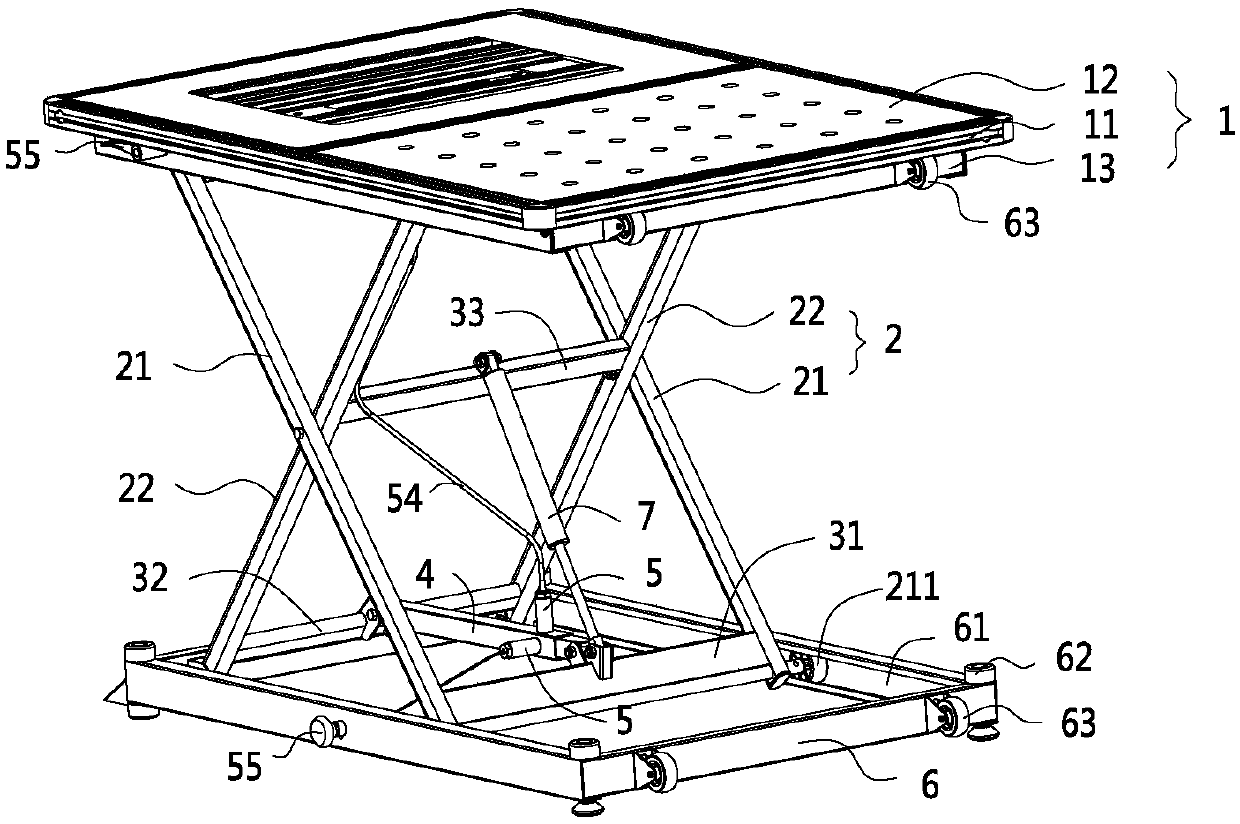

Lifting working platform

A technology for raising and lowering workbenches and operating platforms, which is applied in the direction of lifting frames and lifting devices, which can solve the problems of high manufacturing cost, inconvenient, and affecting work efficiency, and achieve the effect of low cost, simple structure, and good coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

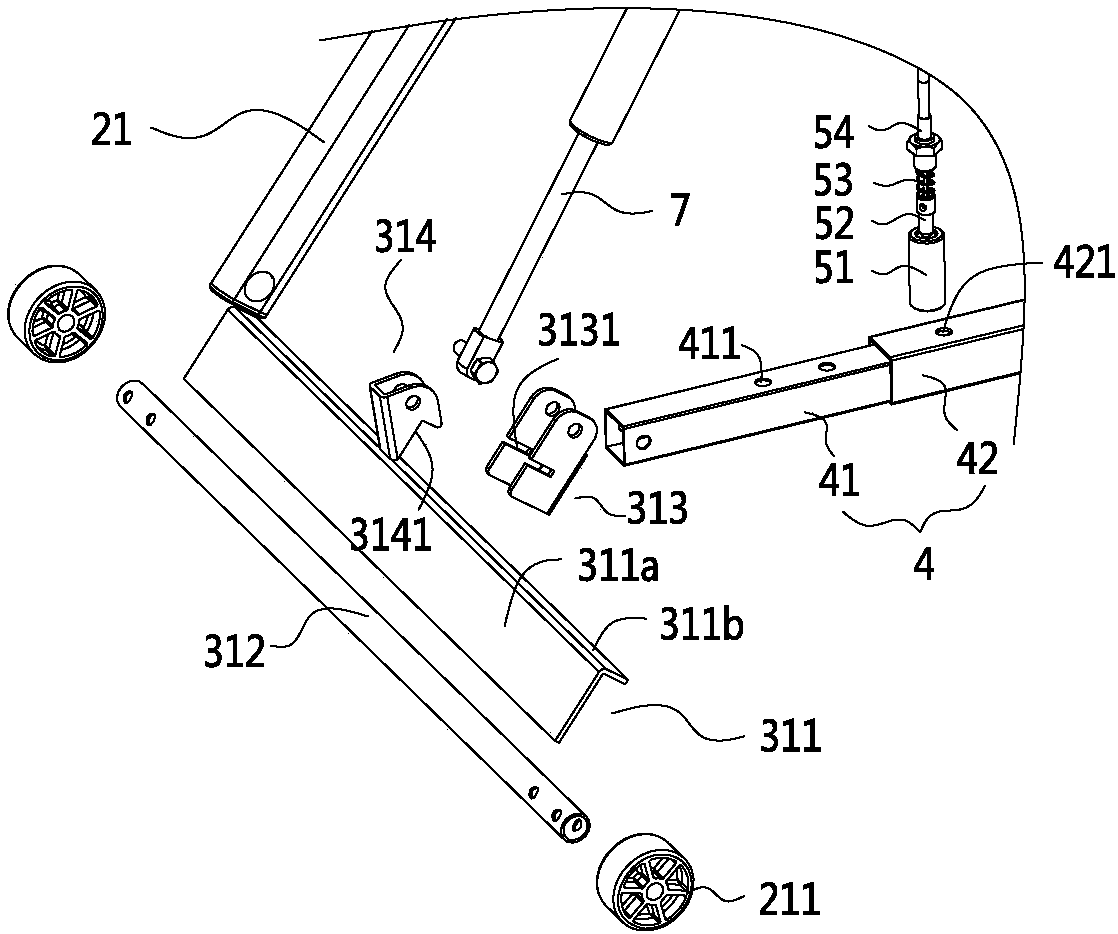

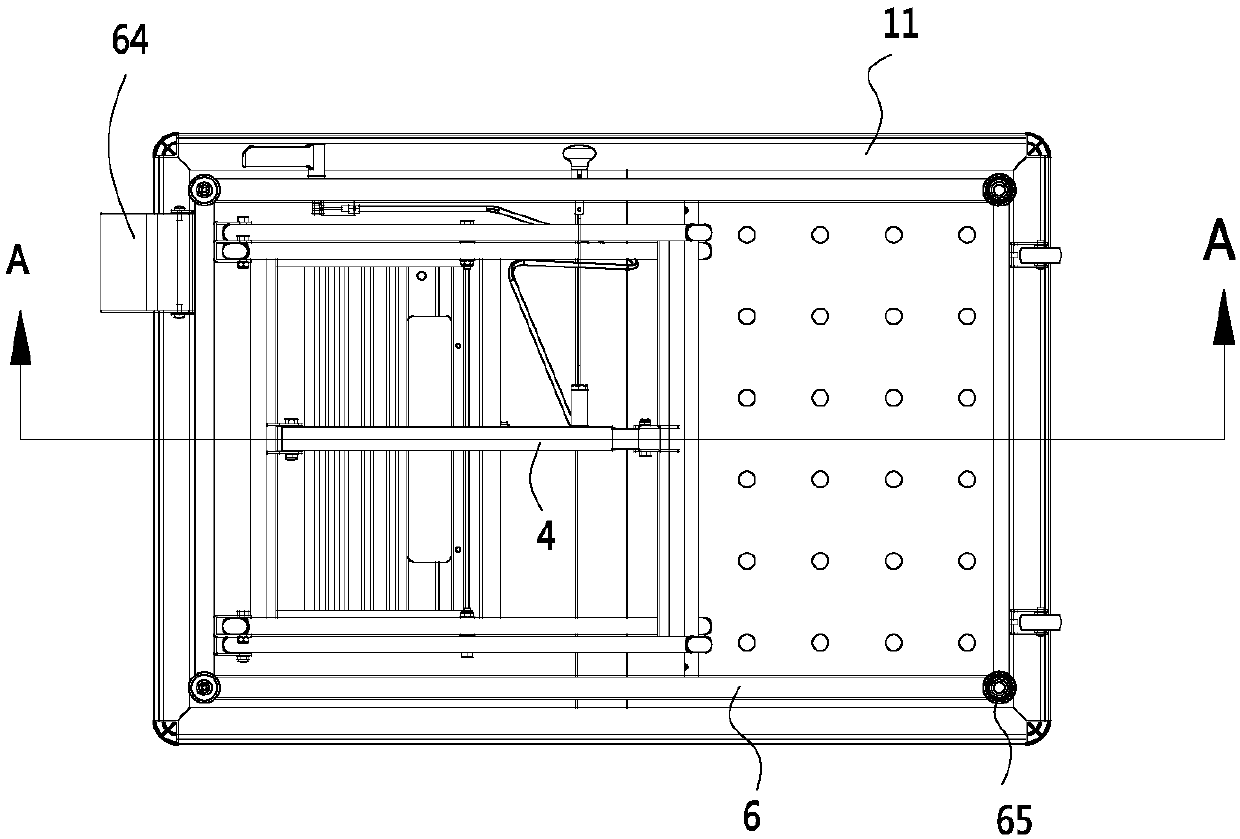

Examples

Embodiment 2

[0069] The difference from Embodiment 1 is that one side of the lifting fork in Embodiment 1 is fixedly hinged with the operating platform and the base, while in this embodiment the entire lifting fork is slidingly connected with the operating platform and the base, that is, the first The top end of the first fork rod is slidably connected with the operation platform, and the bottom end is slidably connected with the base; the top end of the second fork rod is slidably connected with the operation platform, and the bottom end is slidably connected with the base.

Embodiment 3

[0071] The difference from Embodiment 1 is that in this embodiment, the first connecting rod and the lifting fork, and the second connecting rod and the lifting fork are all rotationally connected, that is, the first connecting rod and the first fork The rods are connected in rotation, the second connecting rod is connected in rotation with the second fork rod, and the bushing is fixedly connected with the first connecting rod and the second connecting rod.

[0072] The third connecting rod can be selected to be rotationally connected with the second fork rod, while the telescopic element is fixedly connected with the third connecting rod. Fixedly connected, the telescopic element is hinged with the third connecting rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com