Implementation method of reinforcement cage forming device for pile hole foundation

A steel skeleton and forming device technology, applied in the field of building construction, can solve the problems that the strength of pile holes cannot meet the requirements of building construction, the effect of transverse reinforcement welding is not ideal, and the distribution of transverse reinforcement is uneven, so as to avoid swing and radial swing. Eliminate and improve the effect of distribution uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

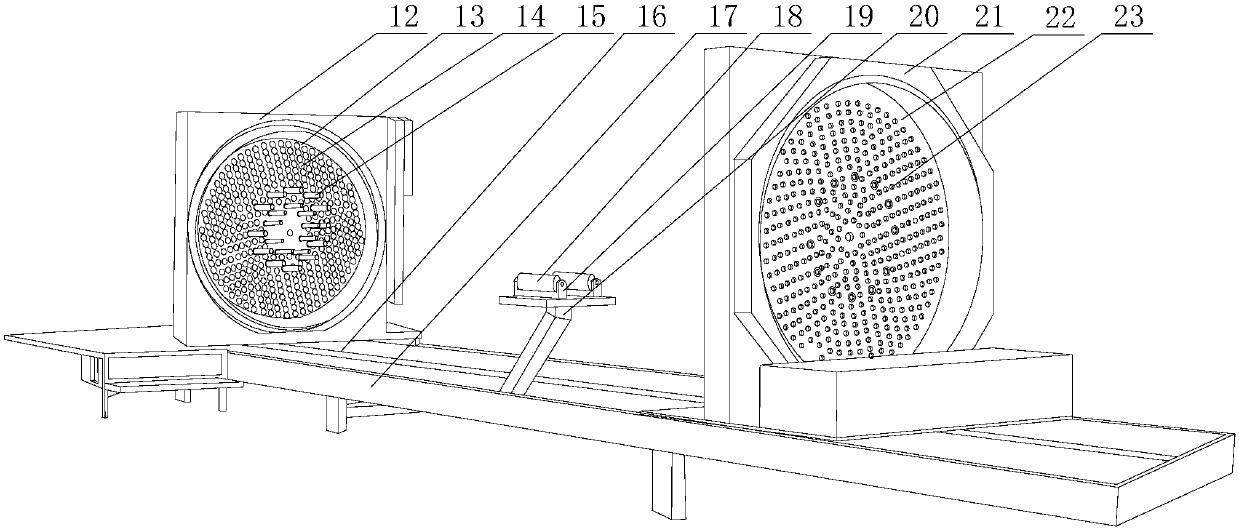

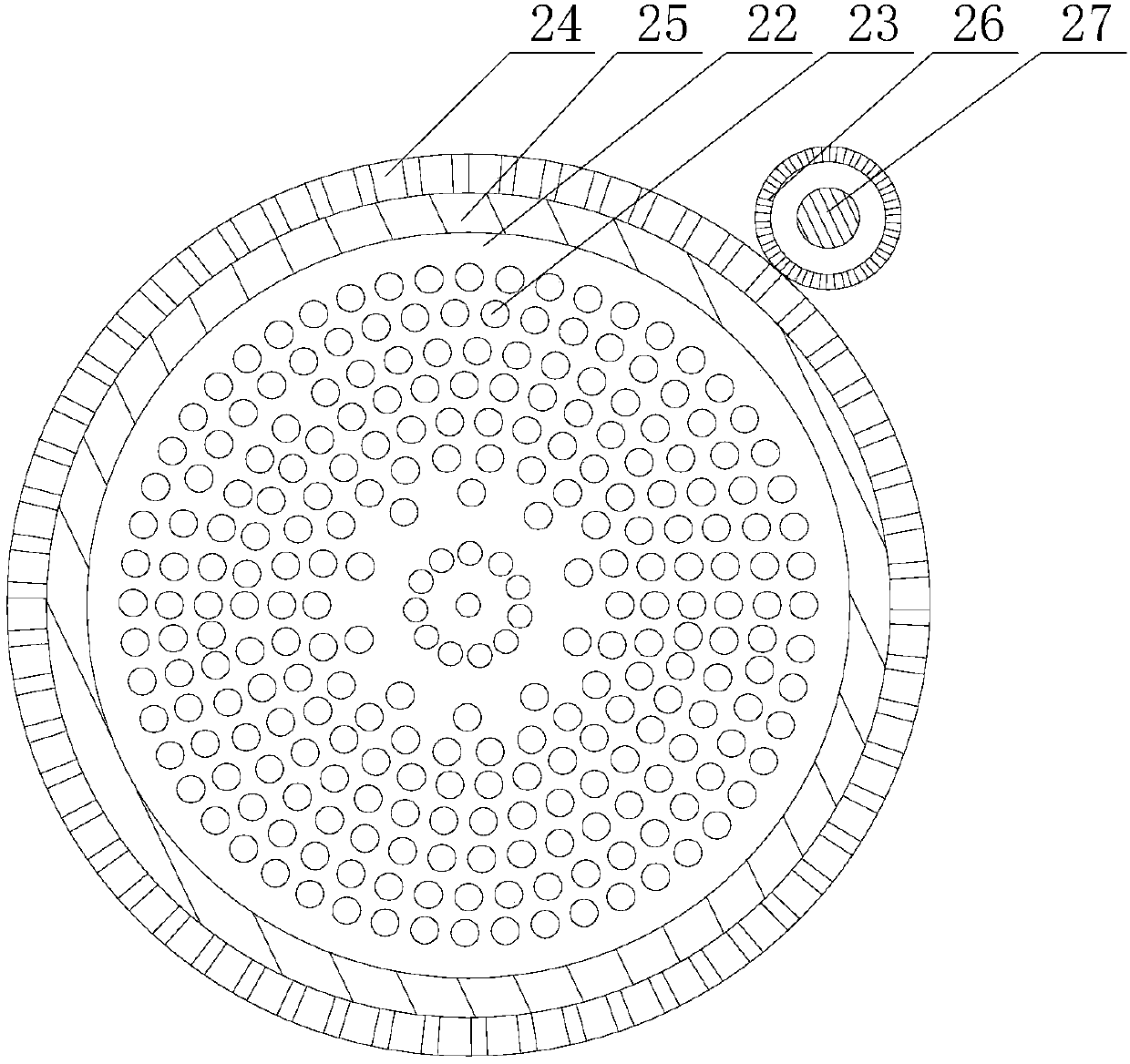

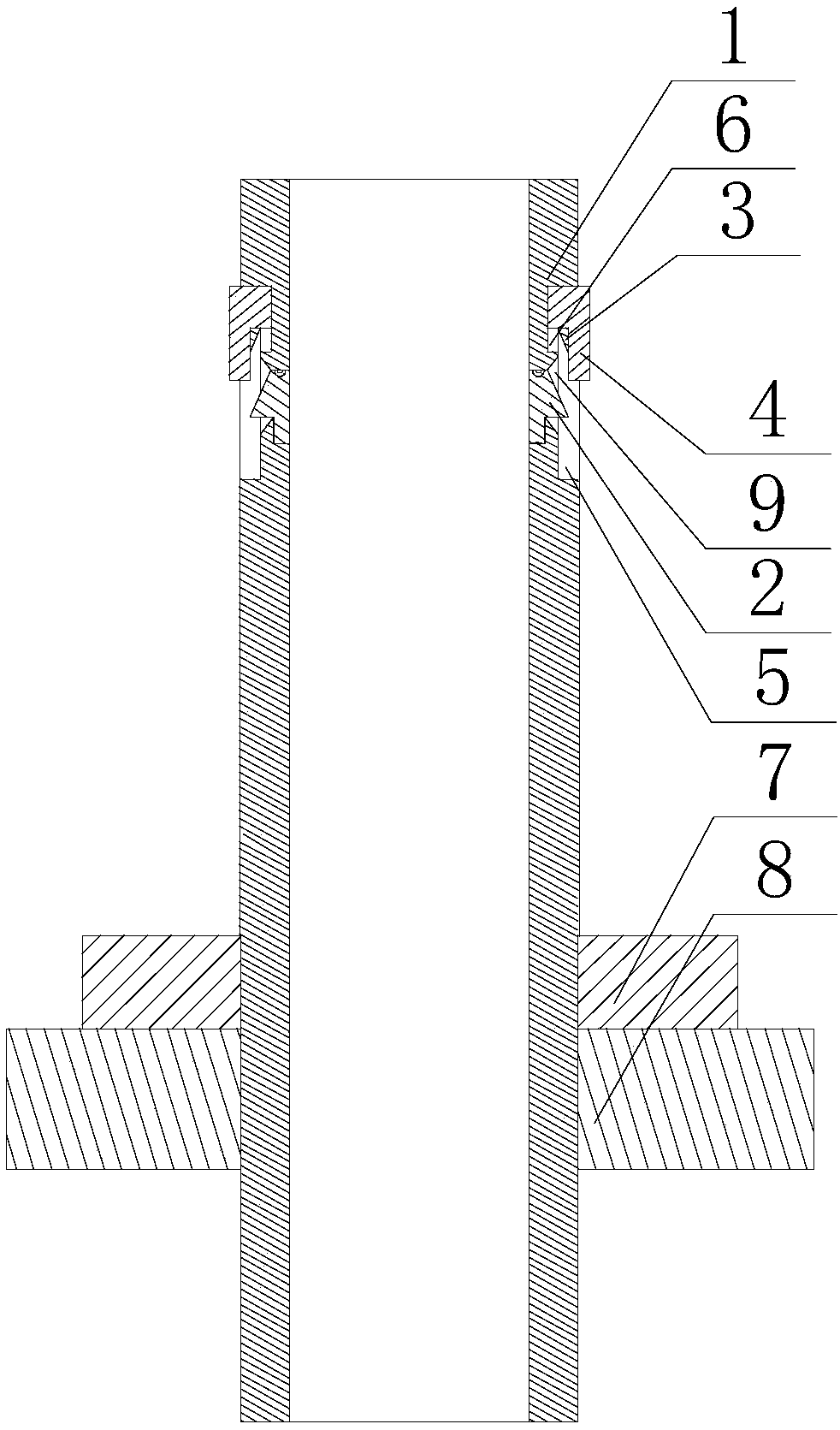

Embodiment 1

[0029] Such as Figure 1~5 As shown, this embodiment includes the following steps: including the following steps: first, fix a plurality of fixing components on the first turntable and the second turntable respectively, so as to form two concentric and equal-diameter circles; Adjust the distance between the first support plate and the second support plate according to the length, and then insert the multiple longitudinal ribs required by the reinforcement cage into the butt holes and the fixing components on the mounting holes in sequence, and start the machine fixed on the second turntable. The motor, the motor drives the gear to mesh with the toothed belt, so that the second turntable starts to rotate inside the two bearings, the first turntable is linked through the longitudinal ribs, and the first turntable also rotates synchronously while the second turntable rotates; the transverse ribs According to the spiral trajectory, it is distributed on the skeleton structure forme...

Embodiment 2

[0034] Such as Figure 1~5 As shown, in this embodiment, transition arcs 11 are respectively provided on both sides of the contact block 10. When the pressure block 2 rotates along the circumferential direction of the annular groove 9 to contact with the contact block 10, the inner side wall of the pressure block 2 and the A smooth transition is realized between the outer side walls of the contact block 10 . When the pressure ring 4 is adjusted to be in contact with the outer side wall of the contact block 10, since the inner peripheral wall of the protrusion 3 is smooth, the two ends of the contact block 10 on the circumferential track of the limit groove 5 are likely to collide with the inner peripheral wall of the protrusion 3. Scratching causes the protrusion 3 to be damaged, so that the adjustment accuracy of the protrusion 3 in the later period is reduced. For this, the applicant sets excessive arcs at the two ends of the protrusion 3, so that the inner wall of the protr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com