Micro LED device and preparation method therefor, and display apparatus

A LED device, miniature technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of high cost and long transfer process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] A method for preparing a micro-LED device, comprising the following steps:

[0018] S1: preparing nano-LED particles;

[0019] S2: providing nano conductive particles and an adhesive, mixing the nano LED particles, the nano conductive particles and the adhesive to obtain a first mixture;

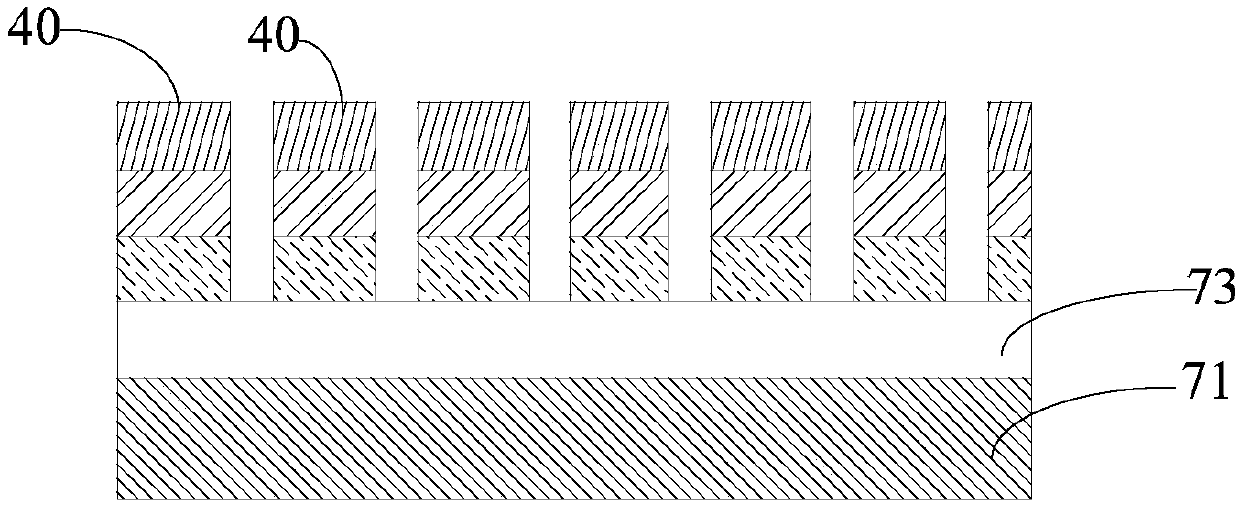

[0020] S3: providing a substrate, and forming a first electrode layer on the substrate;

[0021] S4: coating the first mixture on the first electrode layer, and performing curing treatment to form a composite layer;

[0022] S5: forming a second electrode layer on the composite layer to obtain the micro LED device.

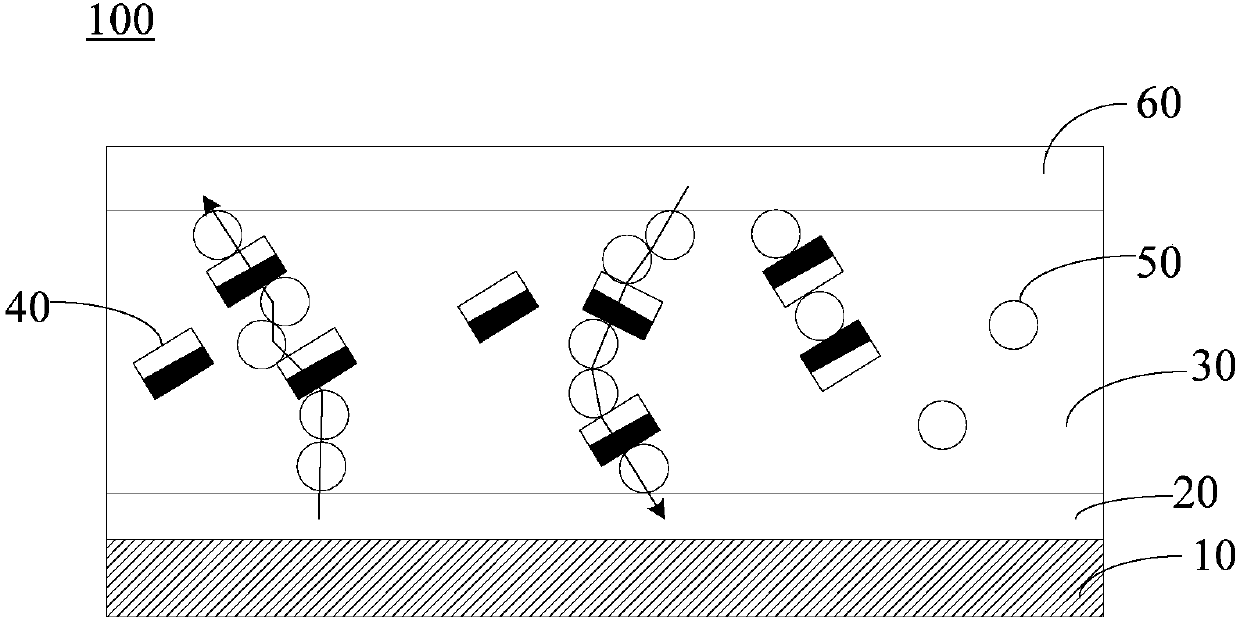

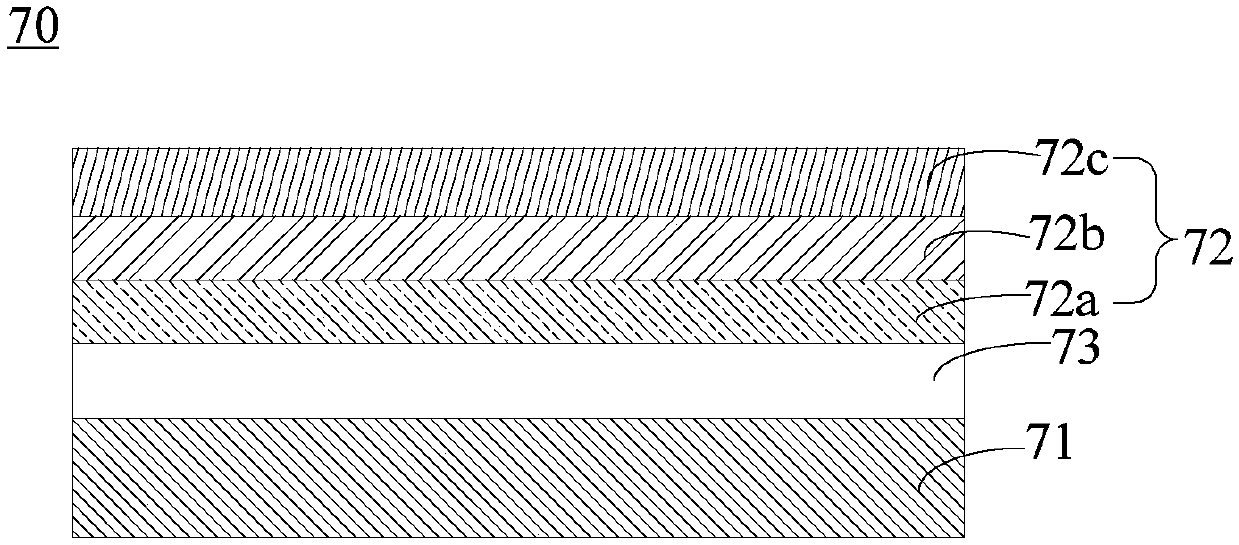

[0023] see figure 1 , the micro LED device 100 prepared by the above method includes the substrate 10, the first electrode layer 20, the composite layer 30 and the second electrode layer 60 which are stacked in sequence, and the micro LED device 100 also includes the substrate dispersed in the composite layer 30. Nano LED particles 40 and nano conductive particles 50 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com