A method for detecting heavy metal content in activated carbon

A heavy metal and activated carbon technology, which is applied in material analysis by observing the influence of chemical indicators, and analysis by chemical reaction of materials, etc., can solve problems such as interference with final colorimetry, difficulty in drawing detection conclusions, and easy discoloration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

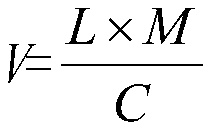

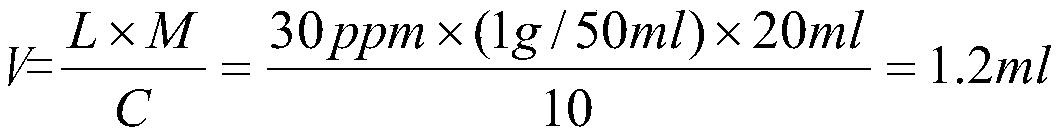

[0023] Taking the heavy metal index of activated carbon not greater than 30ppm as an example, the determination of heavy metal content in activated carbon samples is illustrated:

[0024] 1) Preparation of the test solution

[0025] Take 1.0g of activated carbon, add 20ml of 3mol / L hydrochloric acid and 5ml of bromine test solution, boil for 5 minutes, filter, wash the filter residue with 50ml of boiling water, combine the filtrate and washing solution, and evaporate to near dryness. Then add 1ml of 1mol / L hydrochloric acid, 20ml of water, 5ml of sulfurous acid, and boil the solution until all SO is removed. 2 . Dilute to 50ml with water. Take 20ml of the above solution, put it in a 50ml colorimetric tube, add water to make 25ml, use a pH meter or short-range pH test paper as an external indicator, adjust the pH to 3.0-4.0 with 1mol / L acetic acid, and dilute to 40ml with water.

[0026] 2) Preparation of standard solution

[0027] Take 1.2ml of 10ppm lead standard solution...

Embodiment 2

[0044] Establishment of methodology

[0045] 1 Choice of different color eliminators

[0046] 1.1 Using VC as masking agent

[0047] Take 1.0g of activated carbon, add 10ml of dilute hydrochloric acid and 5ml of bromine test solution, boil for 5min, filter, wash the filter residue with 35ml of boiling water, combine the filtrate and lotion, add an appropriate amount of water to make 50ml, shake well, take 20ml of the test solution In a 50ml colorimetric tube, add 1 drop of phenolphthalein indicator solution. And add ammonia test solution dropwise until the solution is light red, add 2ml of pH3.5 acetate buffer solution and appropriate amount of water to make 25ml, add 0.5g of vitamin C to dissolve.

[0048] Standard solution: Take 1.2ml of 10ppm lead standard solution, put it in a 50ml colorimetric tube, add 2ml of pH3.5 acetate buffer, add water to dilute to 25ml, add 0.5g of vitamin C to dissolve.

[0049] Monitoring solution: Take 20ml of the test solution and place it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com