Rear panel assembly for silencing box shell structure

A structure and box technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of complex processing and assembly, poor reliability, low production efficiency, etc., and achieve simple processing technology, simple structure and sound insulation good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

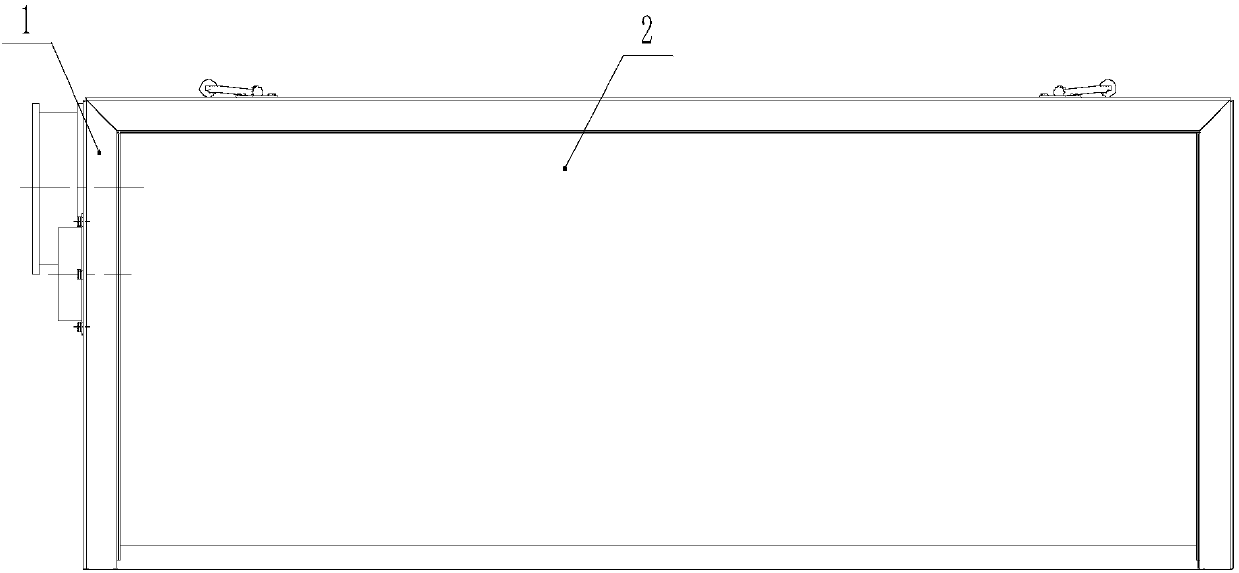

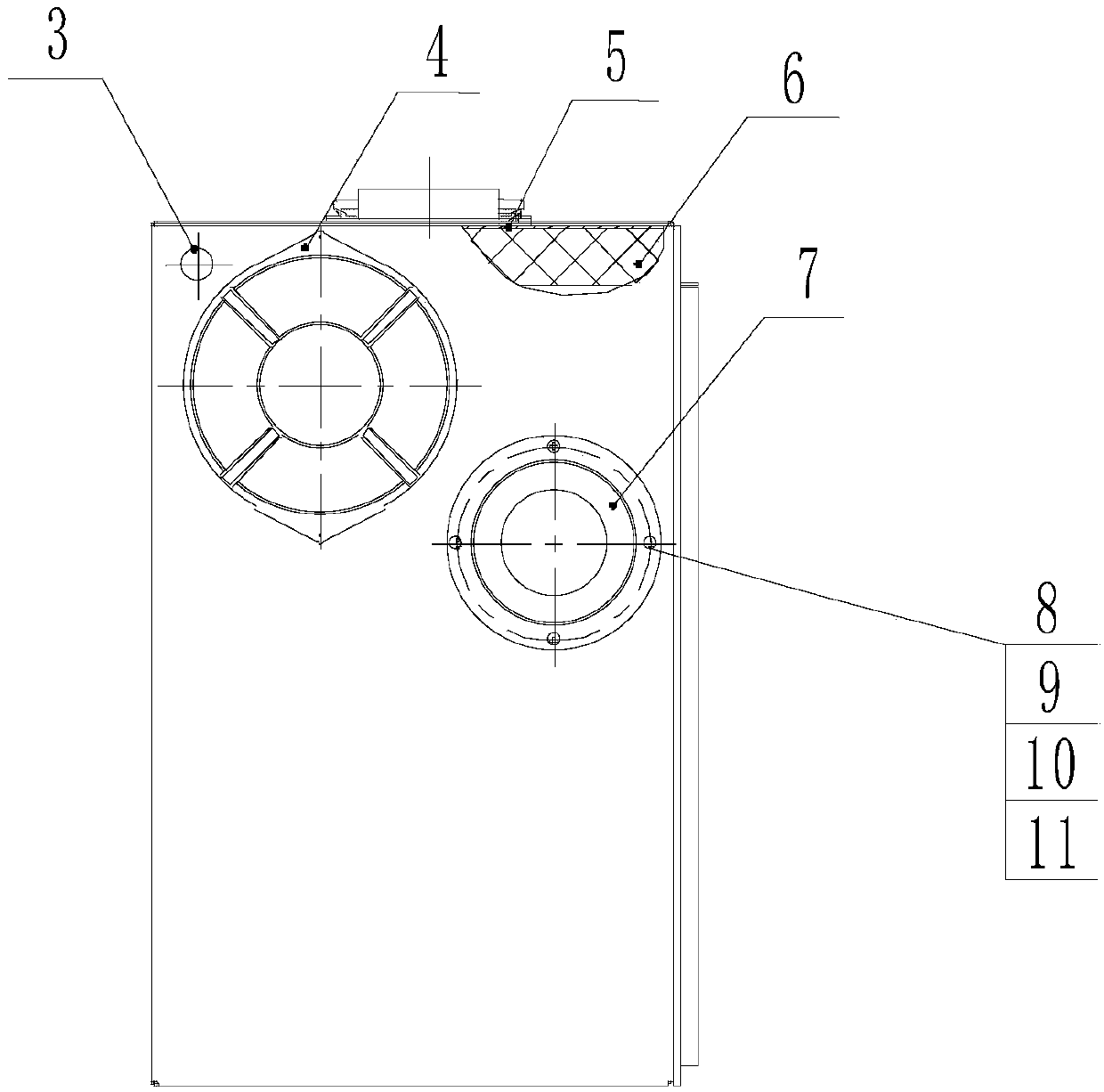

[0021] A rear panel assembly for the shell structure of a silent box, including: rubber strip 1, rear panel 2, protective coil 3, axial flow fan 4, upper damping plate 5, upper sound-absorbing cotton 6, exhaust sealing device 7, cross groove Pan head screw 8, washer 9, spring washer 10, nut 11, handle 12, blind rivet 13, rear sound-absorbing cotton 14, rear damping plate 15, side damping plate 16 and side sound-absorbing cotton 17, the rubber strip 1 fixed Installed on the front side of the back wall 2, the protective coil 3 is installed in the mounting hole on the left side of the back wall 2, and the axial flow fan 4 is fixedly installed on the left side of the back wall 2, so The exhaust sealing device 7 described above is installed on the left side of the rear wall 2 through the cross recessed pan head screw 8, the washer 9, the spring washer 10 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com