Method for placing waste concrete and sealing and storing carbon dioxide in old abandoned mine shaft

A waste concrete and carbon dioxide technology, applied in mining equipment, earthwork drilling, safety equipment, etc., to reduce the greenhouse effect, increase storage capacity, strengthen absorption and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below.

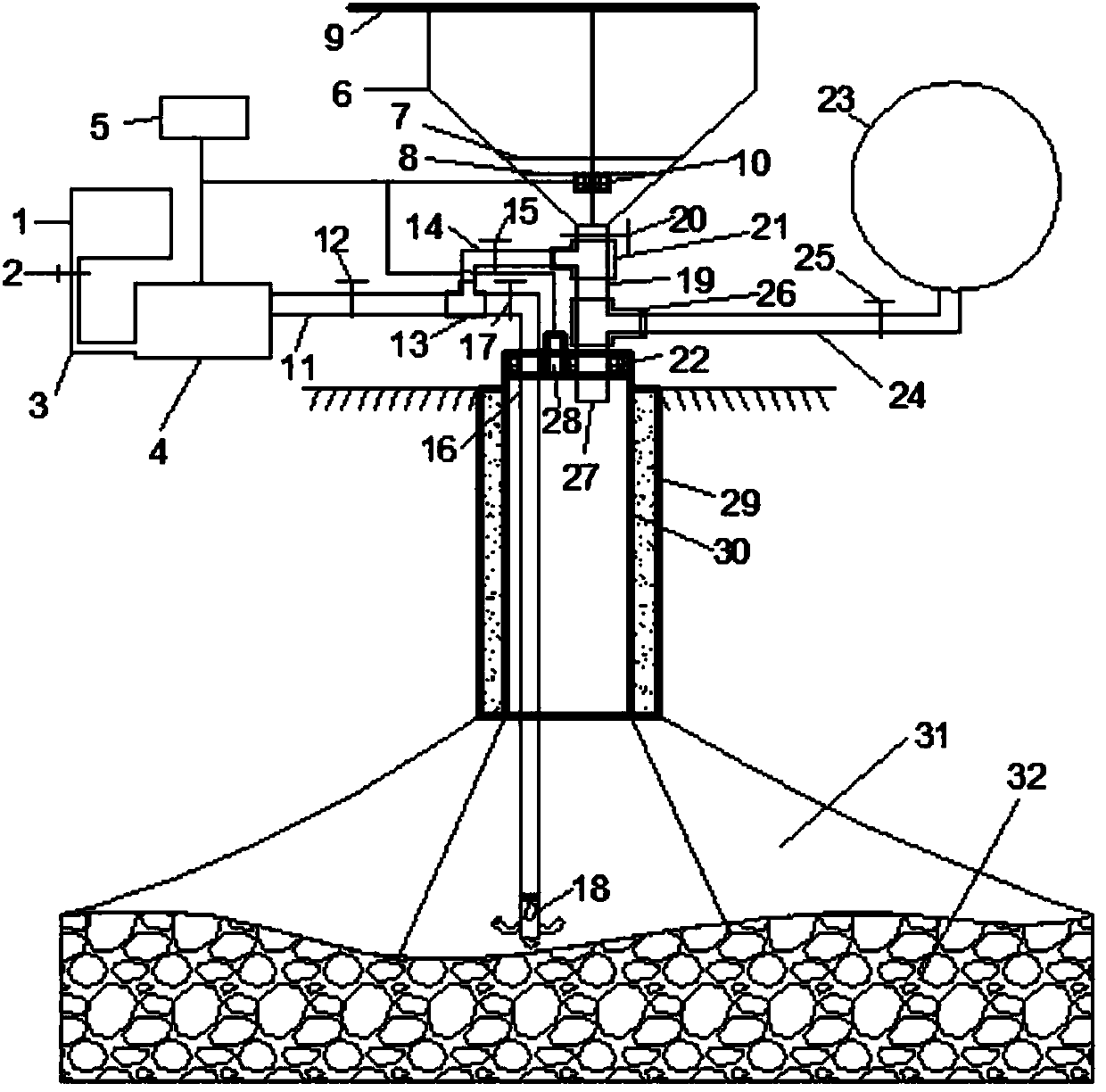

[0021] Such as figure 1 As shown, the present invention includes a water storage tank 1, a first pipeline 3, a pulsating pump 4, a controller 5, a hopper 6, a large aperture screen 7, a small aperture screen 8, a vibrator 10, a second pipeline 11, the first three Through valve 13, third pipeline 14, fourth pipeline 16, fifth pipeline 19, second three-way valve 21, high-pressure sealing cover 22, carbon dioxide storage device 23, carbon dioxide delivery pipe 24, third three-way valve 26. The sixth pipeline 27 and the laser range finder 28, the water storage tank 1 communicates with the inlet of the pulsation pump 4 through the first pipeline 3, and the outlet of the pulsation pump 4 communicates with the first three-way valve 13 through the second pipeline 11. One port of the first three-way valve 13 communicates with one end of the third pipeline 14 and one end of the fourth pipeline 16 respectively, and the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com