Method for producing lightweight concrete product based on calcium carbide slag desulphurization

A technology of lightweight concrete and manufacturing methods, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as environmental damage and large energy consumption, and achieve high energy consumption, cost reduction, and savings The effect of production line investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] (1) pulping

[0056] According to the following formula, each component was mixed uniformly to obtain a desulfurizer, and then added to waste water (from a chemical plant, with a pH of 10) to obtain a desulfurizer slurry. The weight ratio of desulfurizer to waste water is 1:9.

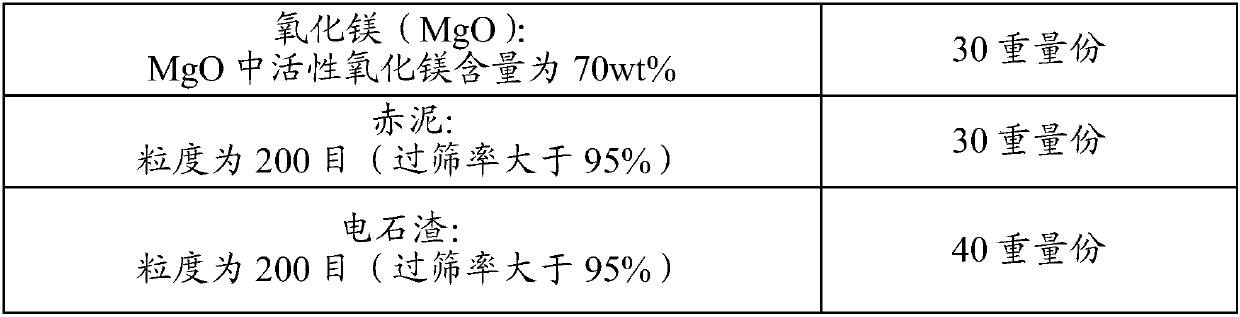

[0057] The formula of desulfurizer is as follows:

[0058]

[0059] (2) Desulfurization

[0060] The flue gas and the desulfurizer slurry are reversely contacted to undergo physical and chemical reactions to obtain the absorption slurry. Refer to Table 1 for desulfurization working condition parameters.

[0061] Table 1. Desulfurization working condition parameters

[0062] serial number

parameter

unit

value

1

Inlet flue gas volume (working condition)

m 3 / h

800000

2

Inlet flue gas volume (standard condition)

N m 3 / h

541935

3

Inlet smoke temperature

℃

130

4

SO2 inlet concentration

mg / Nm 3

800

...

Embodiment 2

[0070] A lightweight concrete product was prepared in the same manner as in Example 1 except for the following formulation and procedure.

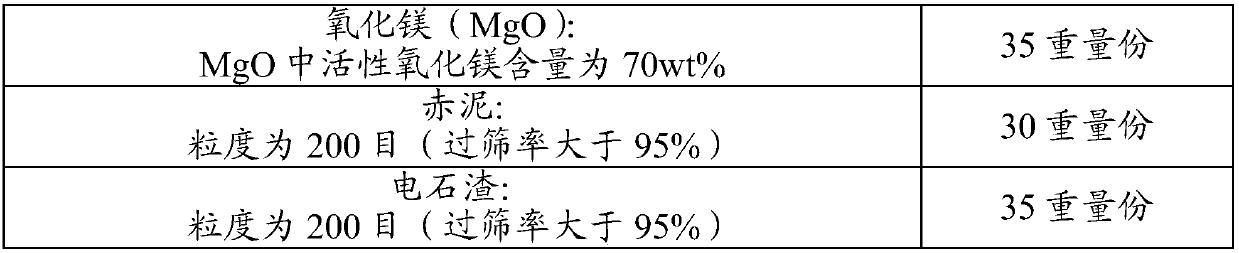

[0071] The formula of desulfurizer is as follows:

[0072]

[0073] In the mixer, at first 30 parts by weight of fine aggregate, 150 parts by weight of desulfurization slurry, 80 parts by weight of fly ash (main component 50wt% SiO 2 , 25 wt% Al 2 o 3 , 9wt% CaO), 80 parts by weight of construction waste powder and 40 parts by weight of magnesium oxide stirred for 5 minutes, then added 35 parts by weight of coarse aggregate and continued to stir for 10 minutes. The average particle size of all raw materials is less than 20mm.

[0074] The desulfurization effect of Example 2 is shown in Table 2, and the performance test results of the lightweight concrete products of Example 2 are shown in Table 3.

Embodiment 3

[0076] A lightweight concrete product was prepared in the same manner as in Example 1 except for the following formulation and procedure.

[0077] The formula of desulfurizer is as follows:

[0078]

[0079] In the mixer, at first 30 parts by weight of fine aggregate, 140 parts by weight of desulfurization slurry, 40 parts by weight of fly ash (main component 50wt% SiO 2 , 25 wt% Al 2 o 3 , 9wt% CaO), 100 parts by weight of construction waste powder and 60 parts by weight of magnesium oxide were stirred for 5 minutes. Then add 40 parts by weight of coarse aggregate and continue stirring for 10 minutes. The average particle size of all raw materials is less than 20mm.

[0080] The desulfurization effect of Example 3 is shown in Table 2, and the performance test results of the lightweight concrete products of Example 3 are shown in Table 3.

[0081] The flue gas desulfurization statistical table of each embodiment of table 2

[0082] Flue gas parameters

[008...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com