Intelligent grapheme 3D printer

A 3D printer and graphene technology, applied in manufacturing auxiliary devices, processing data acquisition/processing, additive processing, etc., can solve problems such as machine idling, motor overheating, and long working hours, so as to reduce the feeding speed and avoid The effect of continuously increasing and reducing the chance of idling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

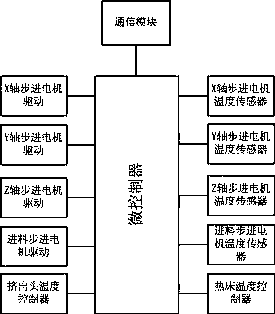

[0017] Such as figure 1 Shown, a kind of intelligent graphene 3D printer, comprises control module and terminal, is characterized in that: described control module also comprises micro-controller, communication module, extrusion head temperature controller, heated bed temperature controller, extrusion head Heating circuit, heated bed heating circuit, X-axis stepping motor drive, Y-axis stepping motor drive, Z-axis stepping motor drive, feeding stepping motor drive, X-axis motor temperature sensor, Y-axis motor temperature sensor, Z-axis Motor temperature sensor and feed motor temperature sensor; the communication module, extrusion head temperature controller, hot bed temperature controller, X-axis stepping motor drive, Y-axis stepping motor drive, Z-axis stepping motor drive,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com