Multipurpose cold press convenient to load and unload

A cold press, a convenient technology, applied in the field of cold presses, can solve the problems of lower platen collision, non-adjustable distance, and adjustment of the lower platen for processing plates, etc., to achieve adjustable distance between hydraulic cylinders, convenient loading and unloading of plates, The effect of convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

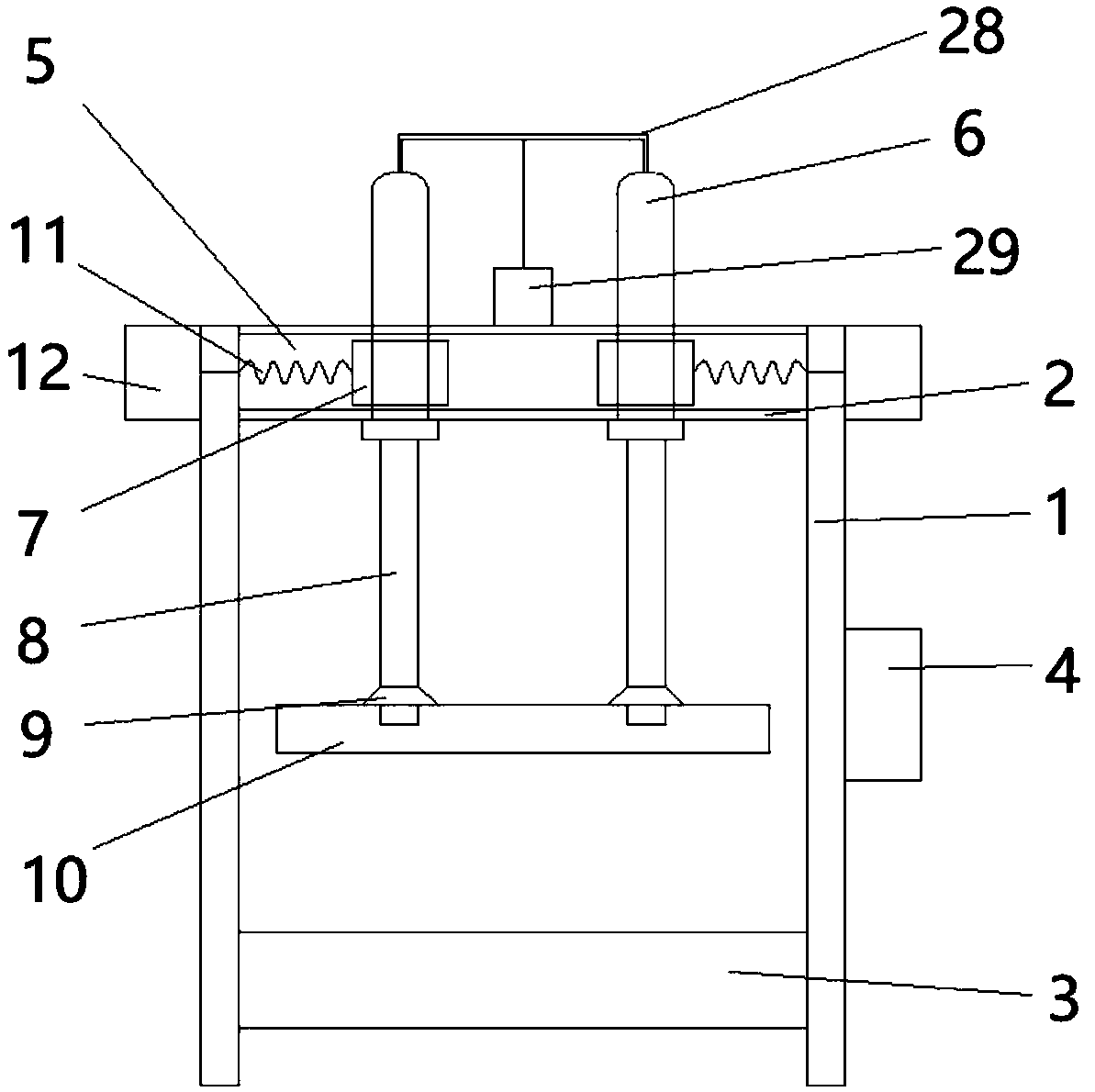

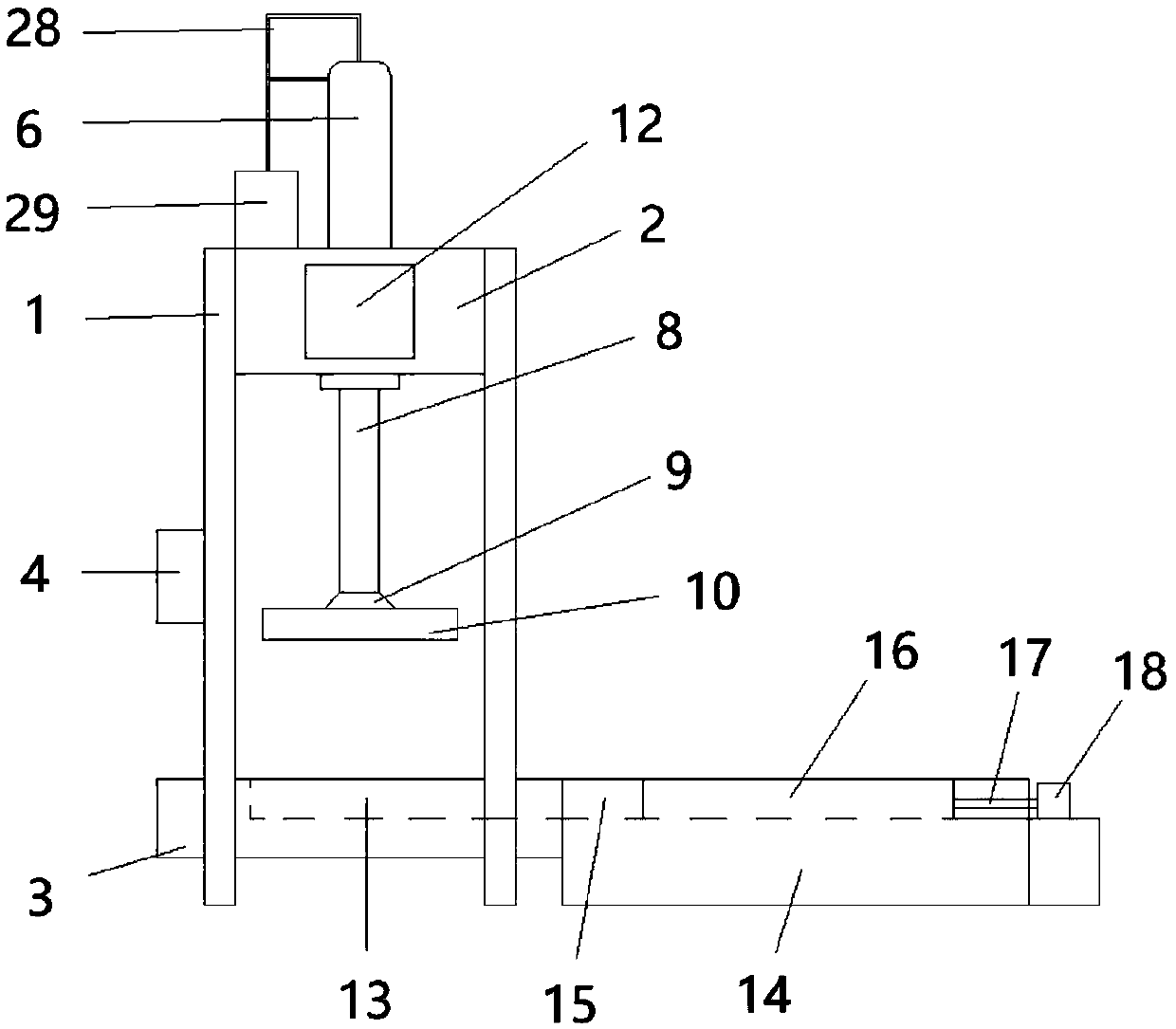

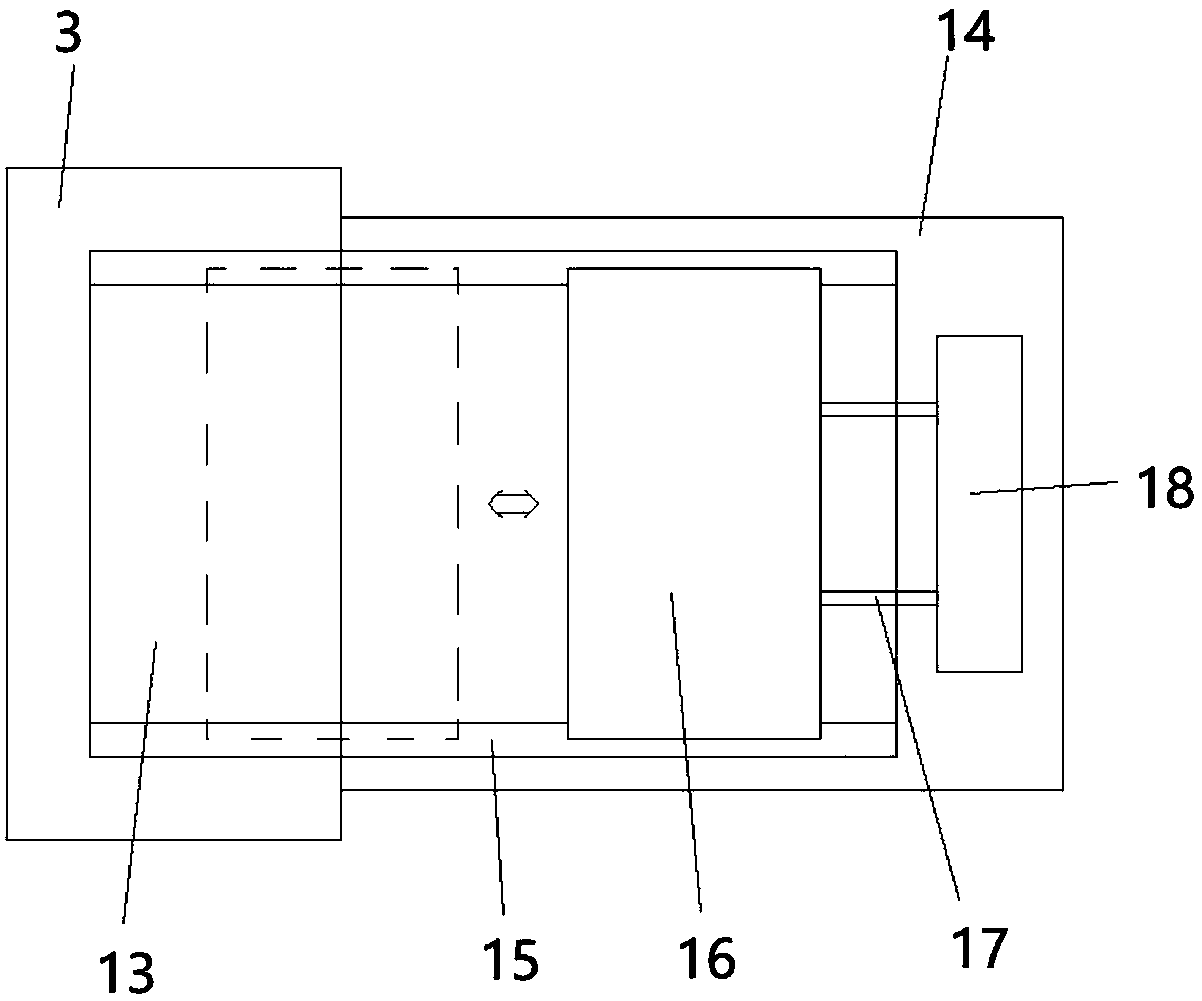

[0017] Embodiment: a kind of convenient multi-purpose cold press machine for loading and unloading, the structure is as follows Figures 1 to 7 As shown, it includes a pair of columns 1, an upper top plate 2 and a lower bottom plate 3 are respectively arranged between the columns 1, and an electric control cabinet 4 is arranged on the column 1; 2. There is a pair of hydraulic cylinders 6 above. The hydraulic cylinders 6 are connected to the first slideway 5 through the slider 7 arranged in the first slideway 5. The piston rod 8 is connected to the bottom of the hydraulic cylinder 6. The bottom of the piston rod 8 is pressed The block 9 is connected with a lower pressing plate 10, and the slider 7 is connected with a first push rod motor 12 through a screw rod 11; the surface of the lower base plate 3 is provided with a cuboid indentation 13, and one side of the lower base plate 3 is provided with a material placement platform 14, The material placement platform 14 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com