Cold heading forming process for manufacturing dowel slotted screws and cold heading module

A forming process and cold heading technology, which is applied in the field of double-head cut-tail grooved screw manufacturing, can solve the problems of low processing efficiency, low part strength, long production cycle, etc., and achieve high production efficiency, complete metal flow lines, Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

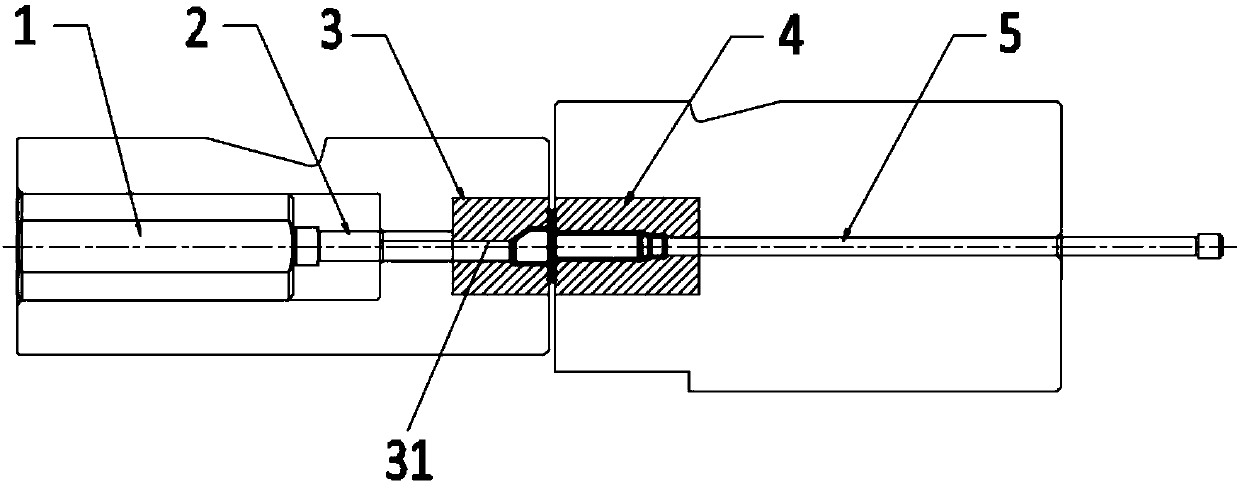

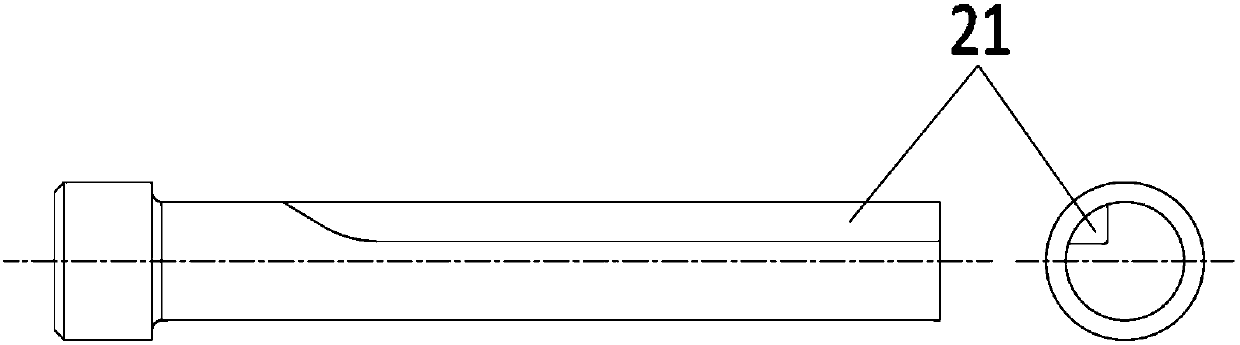

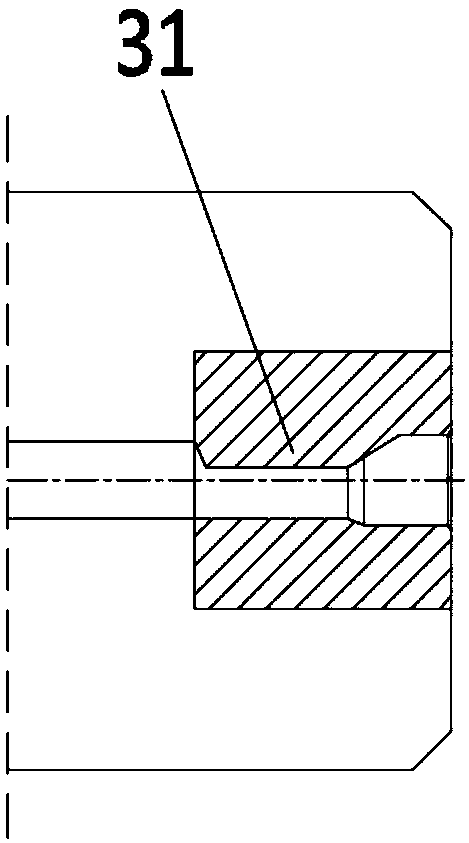

[0021] like Figure 1 to Figure 3 As shown in the figure, this embodiment provides a cold heading forming process for manufacturing a double-head cut-tail groove screw, which is specifically carried out according to the following steps: 1. Prepare raw materials: cut the wire rod with scissors; 2. Cut the wire rod in step 1 , perform the first strong beam to form the third threaded part C; 3. The parts processed in step 2 are subjected to the second strong beam to form the second threaded part B; 4. The parts processed in step 3 are processed by cold heading The first threaded part A of the die bundle, the cutting tail groove E and the upsetting flange, wherein the cold heading die includes a die spacer 1, a die ejector pin 2, a die inner die 3, a main die inner die 4 and a main die ejector pin 5, and the die The inner wall of 3 is provided with a convex edge block 31, and the right end of the convex edge block 31 is provided with a chamfered edge, and the chamfered edge and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com