Pipe bending tool and pipe bending method

A technology of pipe bending and tools, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems that the bending pipe cannot meet the assembly requirements and the size of the parts is difficult to guarantee, and achieves beneficial cost control, guaranteed accuracy, and versatility. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

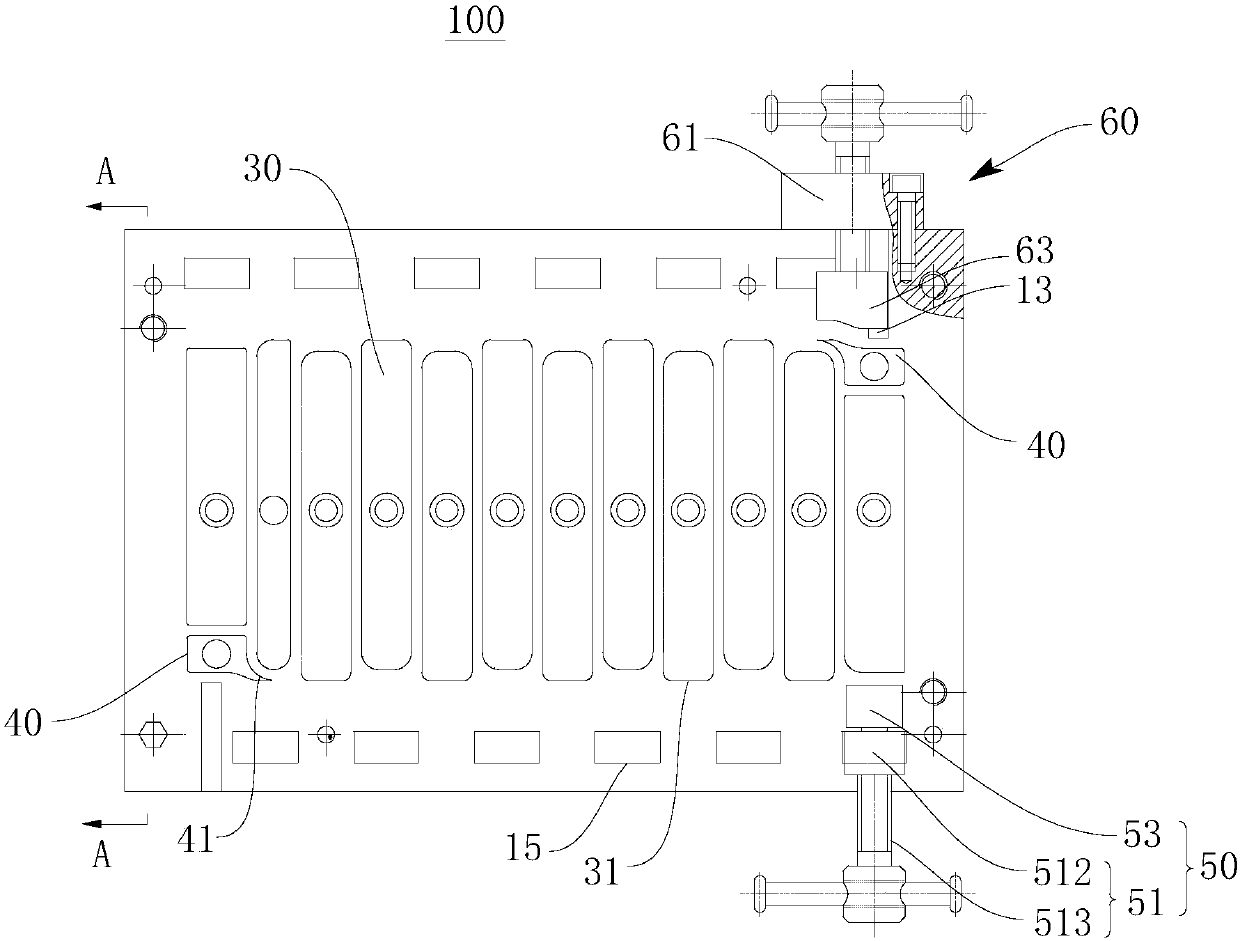

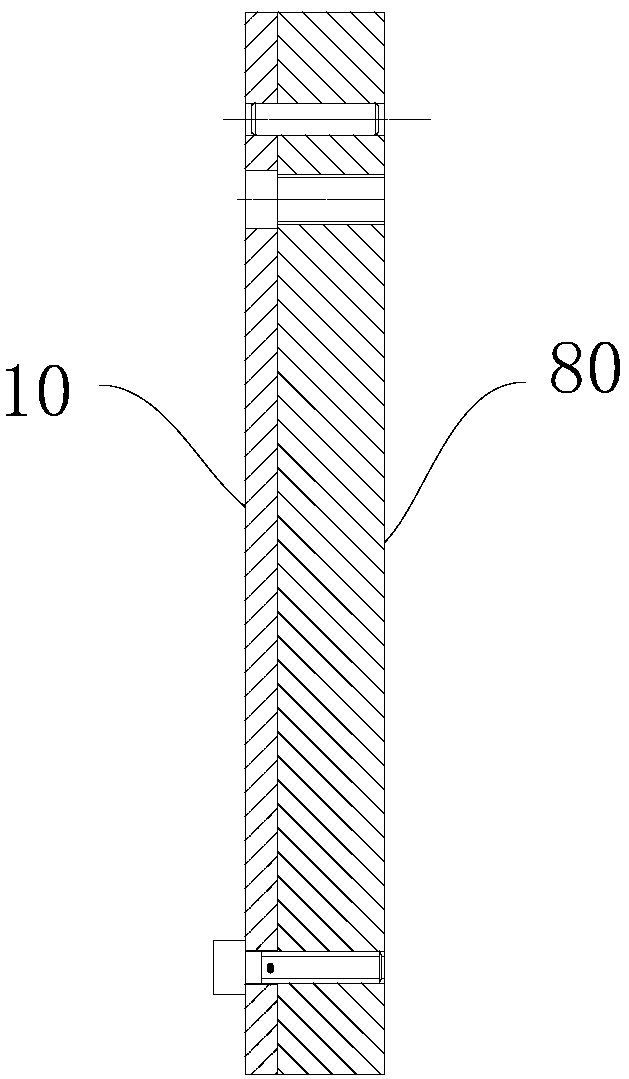

[0048] Please refer to Figure 1 to Figure 8 , this embodiment provides a pipe bending tool 100 and a pipe bending method. The pipe bending tool 100 includes:

[0049] The positioning plate 10, the positioning plate 10 has a concave groove 11, the length and width of the concave groove 11 are set according to the size requirements of the product to be bent;

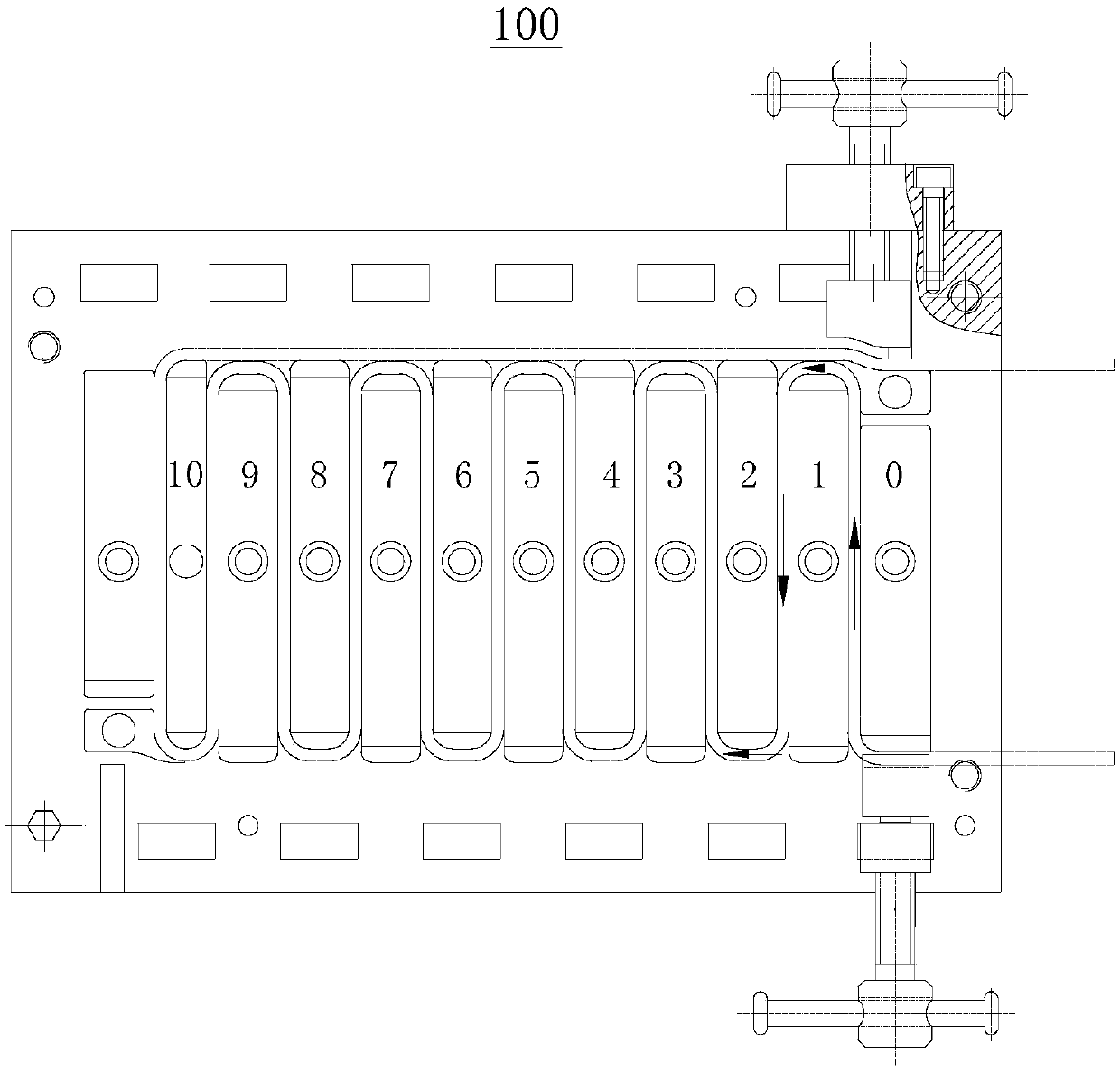

[0050] The first mold core 30, the first mold core 30 fits with the concave groove 11 and is detachably connected with the positioning plate 10, the first mold core 30 includes a bent pipe part 31, and the shape of the bent pipe part 31 depends on the bending of the product to be bent. The shape setting of the fold;

[0051] The second mold core 40, the second mold core 40 includes a guide part 41 for limiting the direction of the thin-walled tube; and

[0052] A fastening device 50, the fastening device 50 is used to push the thin-walled tube and make the thin-walled tube adhere to the elbow portion 31 of the first mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com