Pipeline dredging device for laying power construction cables

A technology for electric power construction and cables, which is applied in the field of dredging devices and dredging devices for cable laying in electric power construction. , Improve the effect of dredging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

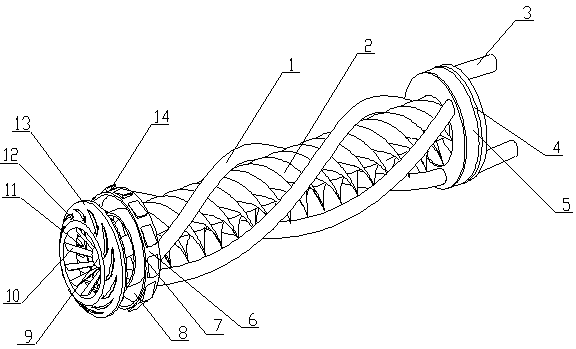

[0027]A pipeline dredging device for electric power construction cable laying of the present invention is realized in the following way: when in use, first judge through the pipeline to determine the position of the hard foreign matter, put the cutting disc (13) into the nozzle closest to the foreign matter, and place the ring The two air intake pipes (3) on the air outlet box communicate with the external high-pressure air source, and the high-pressure air enters the annular air storage box (5) through the air intake pipe (3), and then enters the annular drive box (6) through the spiral conduit (1) ), when the high-pressure gas is at the other end of the spiral conduit (1), they cooperate with each other to form a cyclone, which drives the rotary blade (11) in the annular drive box (6) to rotate, and drives the cutting disc (13) to rotate through the rotary blade (11) Carry out cutting to crush the hard foreign matter step by step. At the same time, the cutting disc (13) drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com