Automatic mechanical arm sorting system based on image recognition

An automatic sorting system and image recognition technology, applied in sorting, manipulators, program control manipulators, etc., can solve problems such as inability to sort and sort various workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

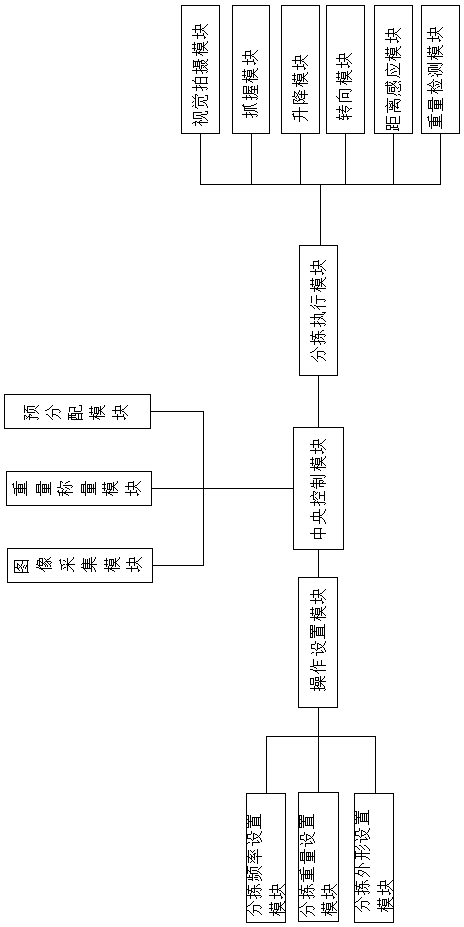

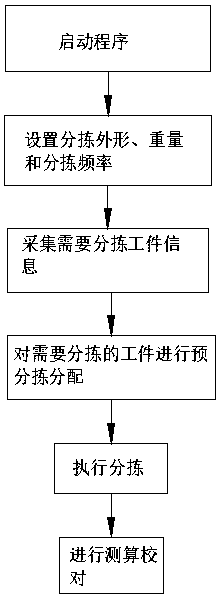

[0015] refer to Figure 1-2 , an image-recognition-based robotic arm automatic sorting system, including a central control module, the central control module is connected to an operation setting module, a sorting execution module, an image acquisition module, a weighing module and a pre-allocation module through signal lines, respectively, The operation setting module includes a sorting frequency setting module, a sorting weight setting module and a sorting shape setting module. The image acquisition module collects the image shape information of the workpiece to be sorted, and the weighing module is used to weigh the quality of the workpiece to be sorted. The pre-al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com