A kind of plant polyphenol modified polymer film and its preparation method and application

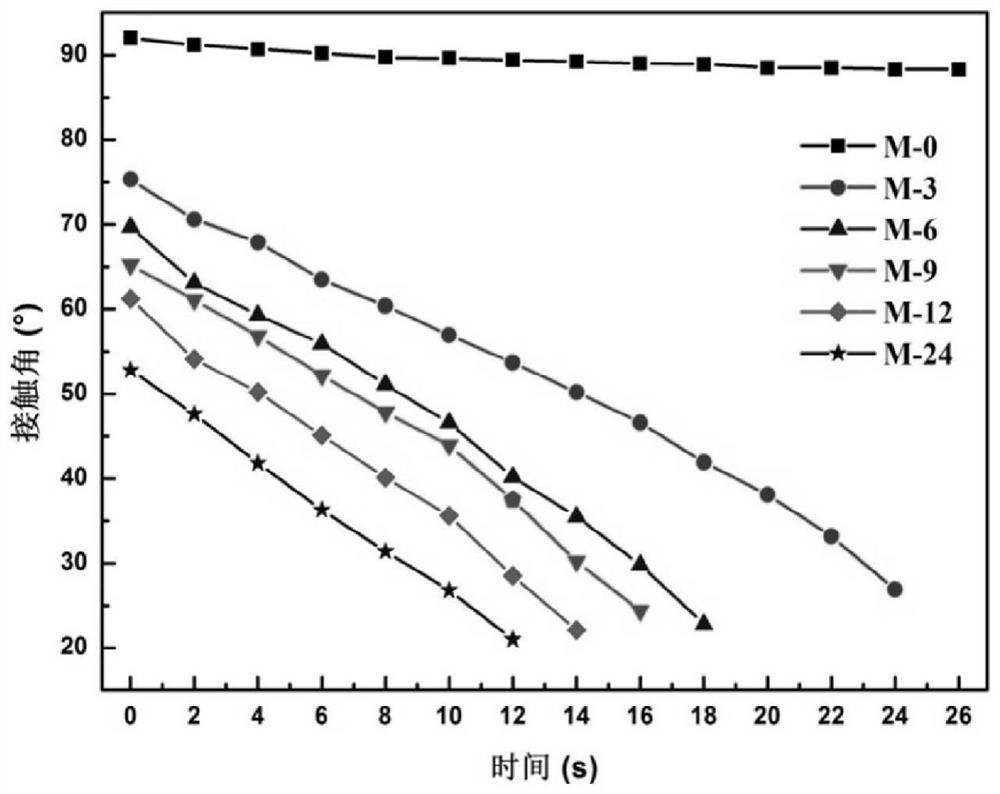

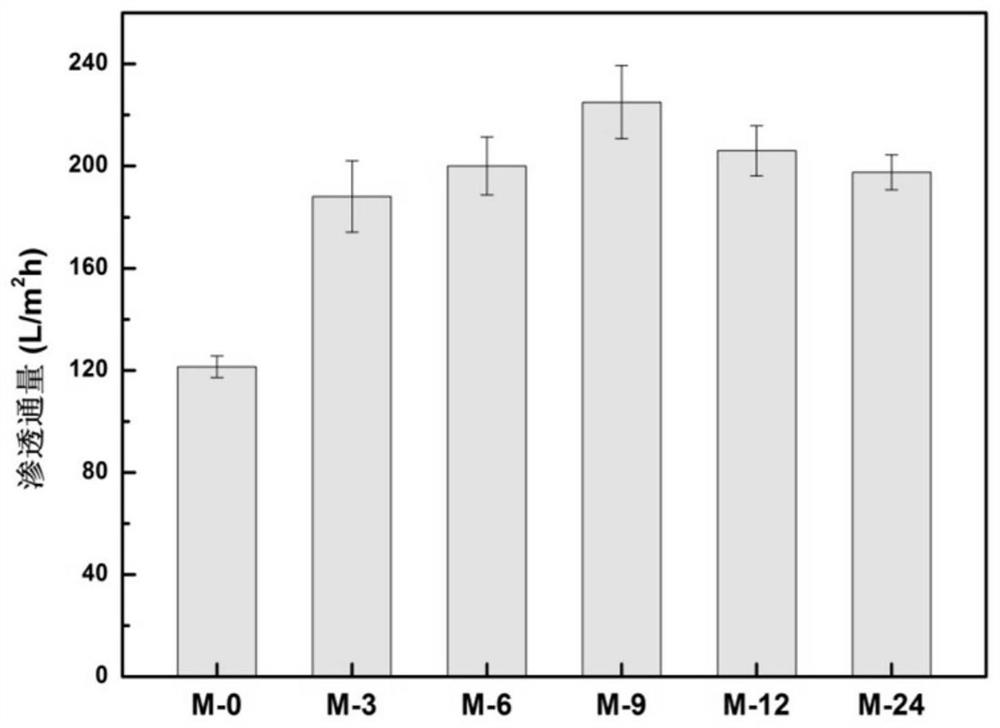

A technology for polymer membranes and plant polyphenols, applied in chemical instruments and methods, membranes, membrane technologies, etc., can solve the problems of easy fouling of polymer membranes, uncontrollable hydrophilization modification, etc., so as to maintain the permeate flux. , good advancement and practicability, the effect of hydrophilic improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation of embodiment 1 Phyto Dove modified polymer film

[0048] 1) Polymer film pretreatment: immerse the polymer film in a beaker containing absolute ethanol for 0.5 h, then soak in deionized water for 0.5 h, and repeat this process 3 times. After treatment, the membrane was placed in deionized water for later use. Wherein, the polymer film is a polyvinylidene fluoride film.

[0049] 2) Prepare a plant polyphenol mixed solution: prepare a Tris buffer solution with a concentration of 1 g / L and a pH of 8.5. Add 1 g of plant polyphenols and 35.06 g of sodium chloride into 1 L of Tris buffer solution, stir for 5 minutes to fully dissolve, and obtain a uniform mixed solution of plant polyphenols; wherein, the plant polyphenols are tannic acid.

[0050] 3) Preparation of plant polyphenol-modified polymer film: immerse the pretreated polymer film in a beaker containing plant polyphenol mixed solution, place it in a constant temperature water bath oscillator at 25°...

Embodiment 2

[0052] The preparation of embodiment 2 Phytopolyphyll modified polymer film

[0053] (1) Polymer membrane pretreatment: immerse the polymer membrane in a beaker containing absolute ethanol for 0.6h, then soak it in deionized water for 0.6h, and repeat this 3 times; The film was placed in deionized water for use. Wherein, the polymer film is a polytetrafluoroethylene film.

[0054] (2) Configure plant polyphenol mixed solution: add plant polyphenol and metal salt to tris (Tris) buffer solution, stir for 3 minutes, get plant polyphenol mixed solution, make the plants of plant polyphenol mixed solution more The final concentration of phenol is 2.5g / L, and the final concentration of metal salt is 20g / L; wherein the Tris buffer solution solution concentration is 2g / L, and the HCl or NaOH aqueous solution with a concentration of 0.1mol / L is used to adjust the pH to 8.0; wherein the plant polyphenol It is a mixture of caffeic acid and cinnamic acid; the metal salt is a mixture of m...

Embodiment 3

[0057] The preparation of embodiment 3 Phyto Dove modified polymer film

[0058] (1) Polymer membrane pretreatment: immerse the polymer membrane in a beaker containing absolute ethanol for 0.5h, then soak it in deionized water for 0.5h, and repeat this twice; The film was placed in deionized water for use. Wherein, the polymer membrane is a polysulfone membrane.

[0059] (2) Configure plant polyphenol mixed solution: add plant polyphenol and metal salt to Tris (Tris) buffer solution, stir for 1min, get plant polyphenol mixed solution, make the plants of plant polyphenol mixed solution more The final concentration of phenol is 0.5g / L, and the final concentration of metal salt is 5g / L; the concentration of Tris buffer solution is 0.5g / L, and the pH is adjusted to 7.0 with HCl or NaOH aqueous solution with a concentration of 0.1mol / L; Phenol is a mixture of rosein, anthocyanin and catechin; the metal salt is a mixture of ferric chloride and aluminum chloride.

[0060] (3) Prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com