Water tank device for silk reeling and picking

A water tank and tank body technology, which is applied in the direction of silk reeling, can solve the problems of affecting the silk production rate, thread tearing, difficult shaking and other problems, and achieve the effects of improving silk production rate, accurate sensing, and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

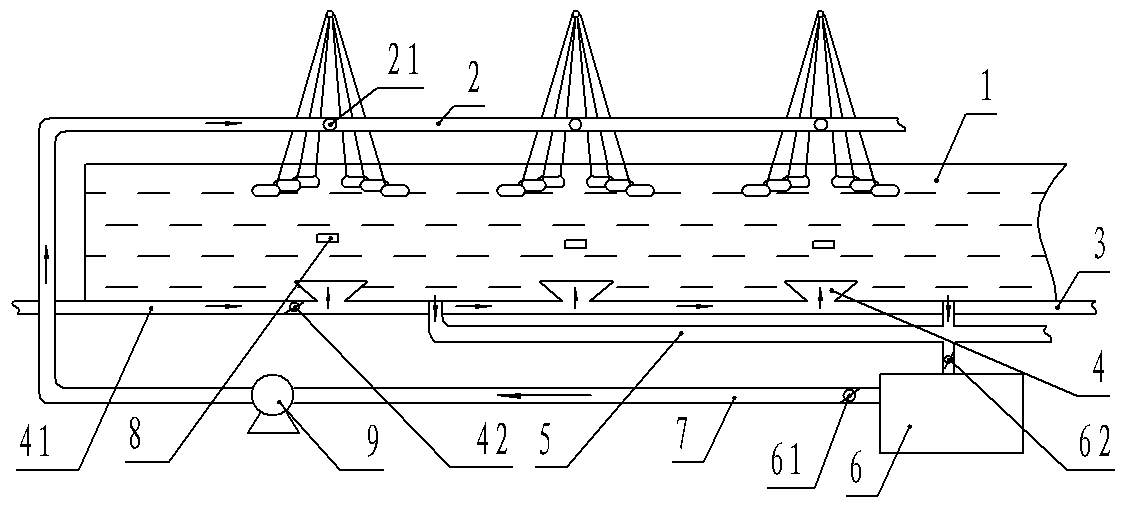

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

[0013] figure 1 The shown silk reeling flume device includes a tank body 1, and the middle and lower part of the wall body of the tank body 1 is provided with a water outlet, and the water outlet is connected with the water outlet pipe 5, and the water outlet pipe 5 is connected with the water inlet pipe of the purified water tank 6, The water inlet pipe of the purified water tank 6 is provided with a first electromagnetic valve 62; the purified water tank 6 has a water outlet, and the water outlet of the purified water tank 6 communicates with the outlet pipe 7 of the purified water tank 6, and the outlet pipe 7 is provided with a pump 9 and a first Two solenoid valves 61; the outlet pipe 7 is connected with the water inlet pipe 2 of the tank body 1; the tank body 1 is provided with a liquid concentration sensor 8 for sensing the concentration of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com