Device for carrier tape bagging and cover tape offset correction after chip package test and process thereof

A technology of chip packaging and deviation correction device, which is applied in packaging, packaging machines, packaging protection, etc., can solve the problems of cover tape detachment and wire drawing, and achieve the effects of avoiding deviation, obvious deviation correction effect, and reducing the volume of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

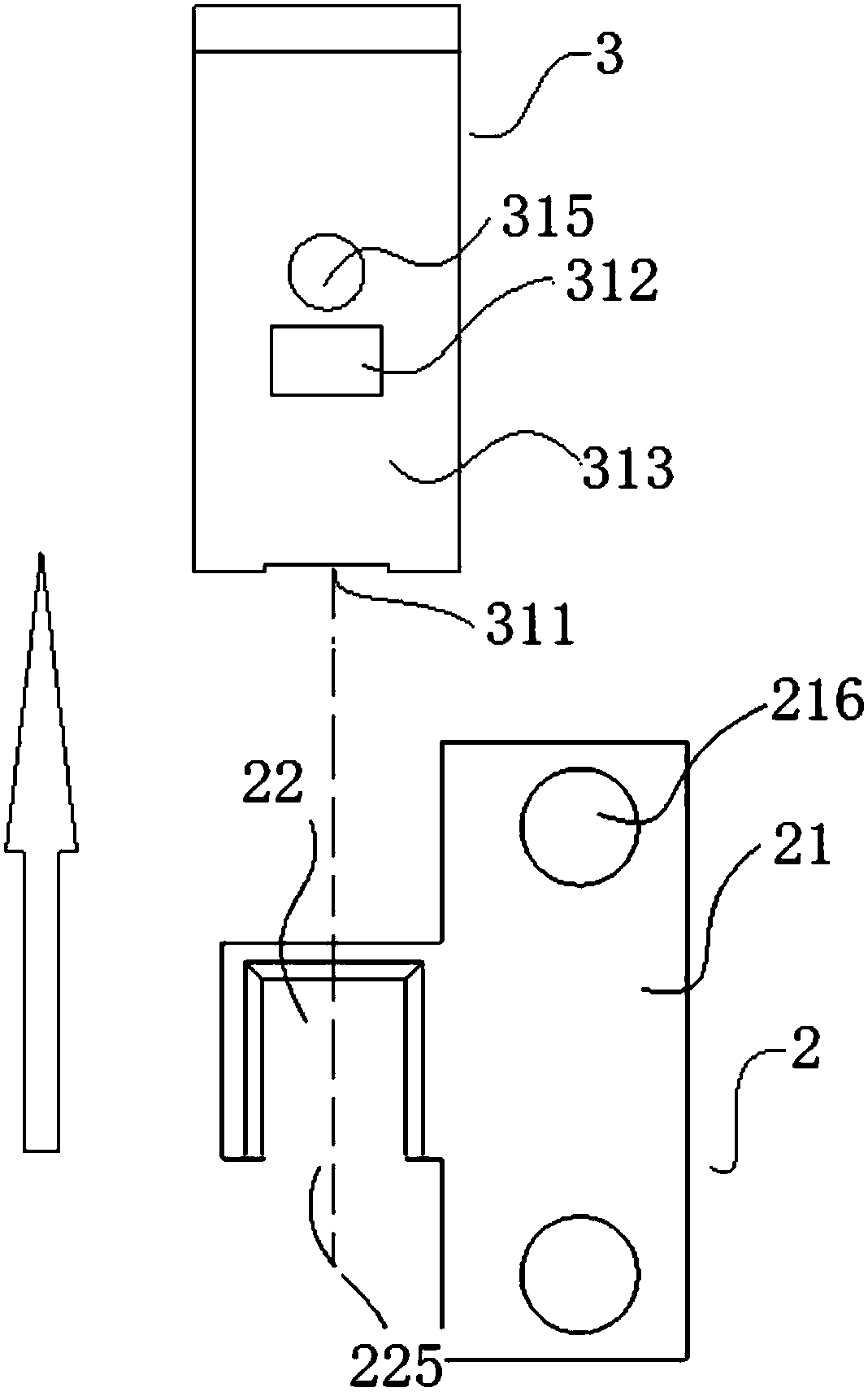

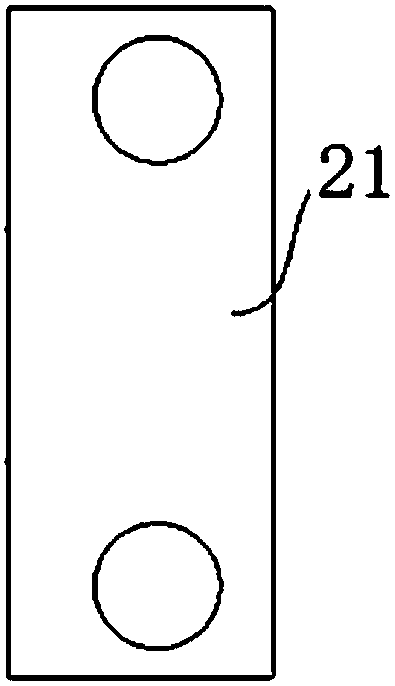

[0059] After the chip packaging test of this embodiment, the carrier tape is put into the bag and the cover tape deflection correction device, such as figure 1 As shown, it includes the carrier tape bagging mechanism 2 and the cover tape offset prevention mechanism 3 arranged in the process order, wherein: as Figure 4 As shown, the carrier tape pocketing mechanism 2 includes a square pressing plate 21 and a braiding window 22 extending from the middle of the square pressing plate 21 to the running direction of the carrier tape; the square pressing plate 21 and the braiding window 22 are fixedly connected as one, through The braiding window guides the suction nozzle to put the chip into the POCKET of the carrier tape, which prevents the pin from touching the edge of the POCKET and causing the pin to become warped; the bottom of the braiding window 22 is opened as an outer opening 225, so that Install other devices in the installation space, such as detection devices; Figure...

Embodiment 2

[0061] The carrier tape of the present embodiment after the chip packaging test is put into the bag and the cover tape deflection correction device, the basic structure is the same as that of embodiment 1, the difference and improvement are that the shape and size of the bottom of the braiding window 22 are consistent with the opening of the bag of the carrier tape, Both are 3.3X3.2mm, forming a straight drop microchannel of the chip to avoid secondary offset when the chip is placed; the soft connection is realized through the cooperation of the elastic mechanism and the directional track mechanism, the elastic mechanism achieves the purpose of buffering, and the directional track realizes The purpose of avoiding offset; the depth of the cover tape groove 311 is greater than the thickness of the cover tape. In this embodiment, the platen groove 311 is 10dmm deep, and the cover tape is 6dmm thick, so as to ensure that the cover tape does not shake back and forth in the cover tape...

Embodiment 3

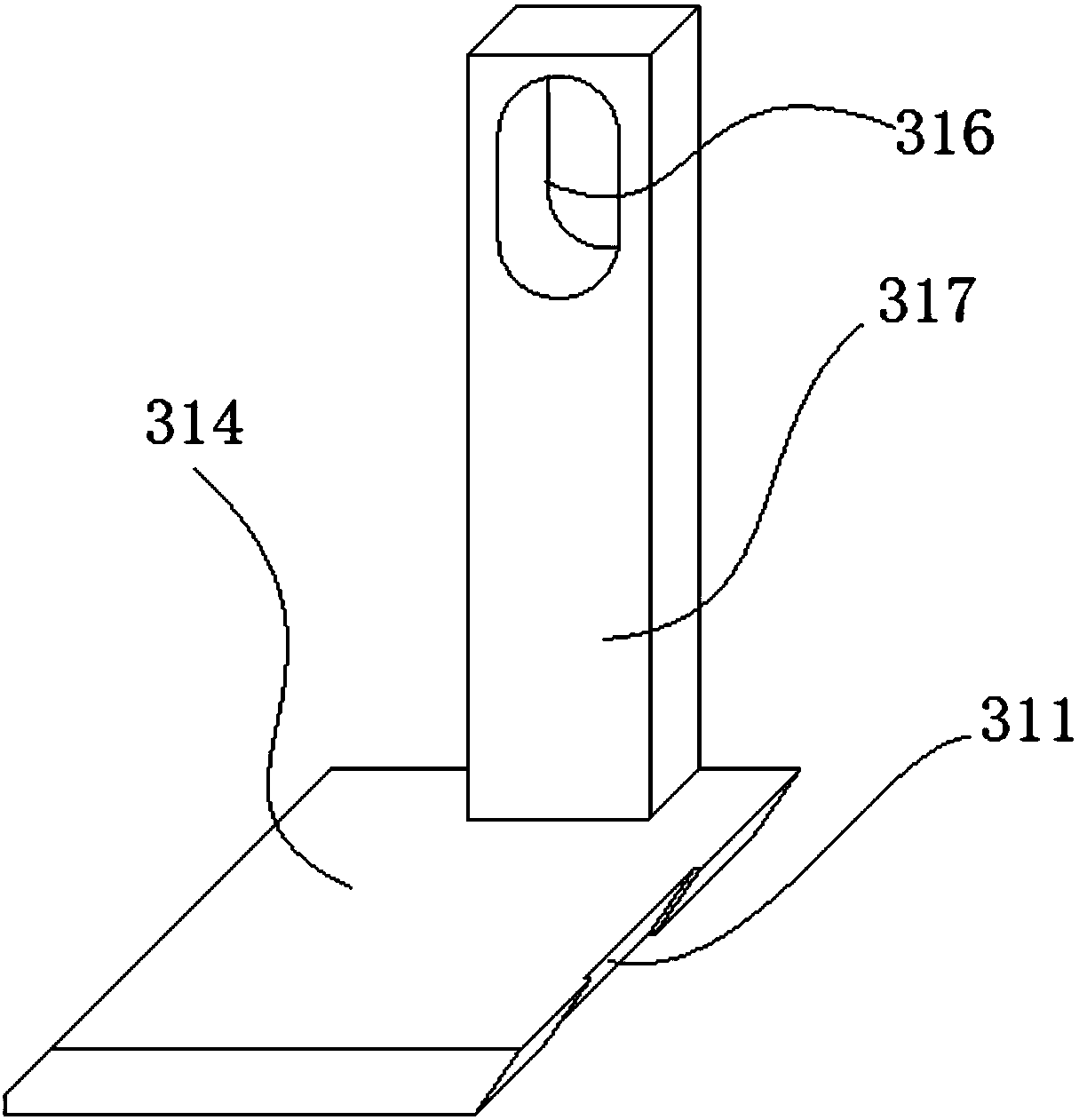

[0063] The basic structure of the carrier tape into the bag and the cover tape deflection correcting device after the chip package test of this embodiment is the same as that of Embodiment 2, the differences and improvements are as follows: Figure 5 As shown, the braiding window 22 includes a square area 221 at the bottom and a receiving area 222 at the upper part. The angle of chip placement is corrected through the receiving interface to prevent the pin from touching the edge of the POCKET. The thickness ratio of the two is 2-4:6- 8. In this embodiment, the thickness ratio of the two is 3:7, and the thickness of the receiving area is larger, almost twice as large, providing a relatively large operating space for deviation correction; the upper surface of the pressure plate 31 is fixed with a vertical pressure plate public rail rod 312; the bottom surface of the support 32 is provided with a support female rail hole 321 that cooperates with the pressing plate male rail rod 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com