Production process of novel cobblestone prefabricated members

A production process and cobblestone technology, which is applied to the pavement paved with prefabricated blocks, manufacturing tools, ceramic molding machines, etc., can solve the problems of low level of mosaic technology, simple and crude patterns, high labor intensity, etc., and achieve simple construction technology Convenient, highly ornamental, beautiful pattern effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

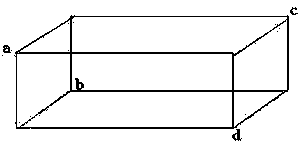

[0021] see figure 1 , the present invention provides a technical solution: a production process of a novel cobblestone prefabricated part, including making a mosaic cobblestone prefabricated part, comprising the following steps:

[0022] ①The parquet cobblestone prefabricated parts are produced in a factory, and molds of different shapes and sizes are made according to customer needs. The molds can be made of bamboo, wood, metal, plastic and other materials. figure 1 It is a rectangular mold.

[0023] ②Please ask professional artists or painters to draw artistic patterns according to the color and size of the pebbles used in advance, and print or etch the pattern on the bottom of the mold. Workers arrange pebbles of different colors and sizes closely according to the pattern requirements at the bottom of the mold, and spread them all over the bottom of the mold, and fill the mold with cement fine sand concrete slurry or colloid in a ratio of 1:1 to 1:1.5, and wait until the...

Embodiment 2

[0027] The invention provides a technical solution: it is necessary to make a prefabricated mosaic cobblestone that can seep water. After the cobblestone is tightly covered with the bottom of the mold and before the concrete slurry or colloid is poured, insert the cobblestone into the gap between the cobblestone and the cobblestone from top to bottom. Thin rods made of degradable material (the length of the thin rod is the same as the thickness of the pebble preform), and then the mold is filled with concrete slurry or glue. After the mosaic cobblestone prefabricated parts are put into use, the thin rods gradually degrade to form seepage channels. Or use a hollow thin rod, and the two ends of the thin rod are blocked with degradable materials.

[0028] Pavement process of permeable mosaic cobblestone prefabricated parts: level the soil ground that needs to be constructed, and spread a layer of crushed stones. The thickness of the crushed stone sub-layer is not less than 5 cm. ...

Embodiment 3

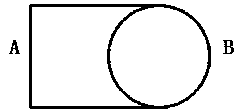

[0030] see figure 2 , the present invention provides a technical solution: the mosaic cobblestone prefabricated parts can be customized according to the path shape and direction changes; The mosaic cobblestone prefab of the , you can also use the "multi-dimensional steering parquet cobblestone prefab" to change the shape and direction of the cobblestone path, such as figure 2 . The specific method of use is: use the regular-shaped "multi-dimensional turning mosaic cobblestone prefabricated part A" and "multi-dimensional turning mosaic cobblestone prefabricated part B" together to realize the change of the direction and shape of the cobblestone path.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com