Dodecagonal spline tooth rotation preventing self-locking check ring

A spline tooth, dodecagonal technology, applied in the field of dodecagonal spline tooth anti-rotation self-locking retaining ring, can solve problems such as failure and low strength, and achieve the effect of sufficient strength, firm and reliable connection, and ability to prevent rotation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

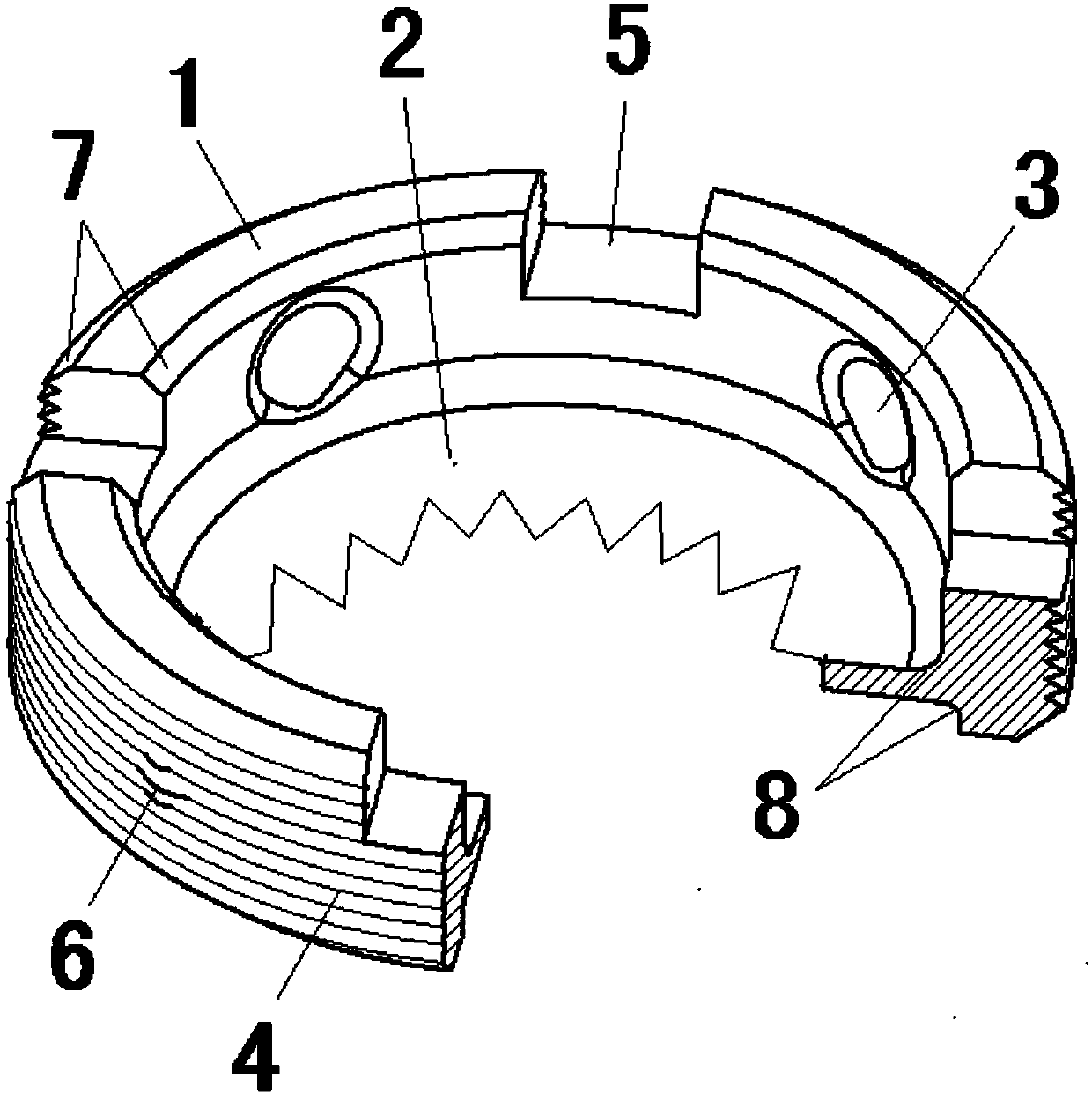

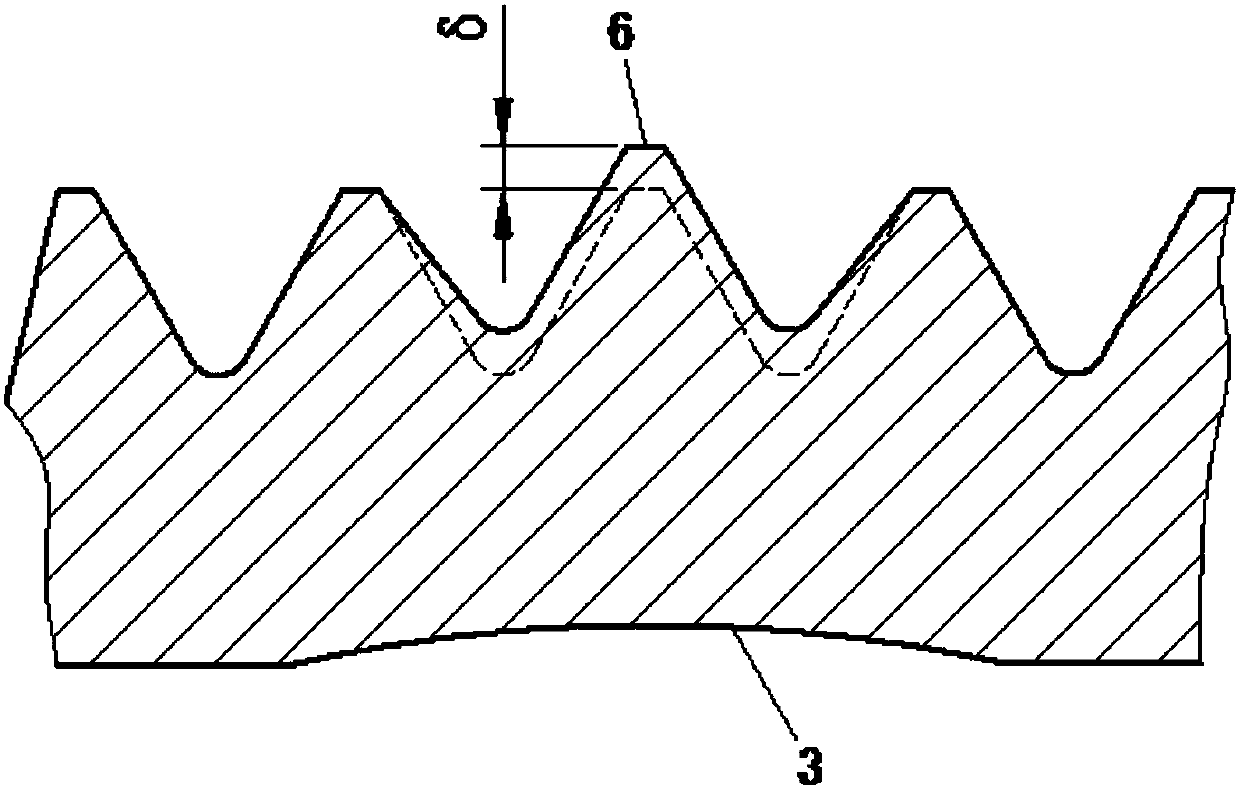

[0016] This example Figure 1-2 As shown, when implementing the present invention, first process the part body 1, then process the external thread 4 on the outer circle of the part body 1, and process the dodecagonal spline tooth hole 2 at the center of the part body 1, and then in the part body 1 Extrude 2 to 4 concave deformation pits 3 on the inner wall where the external thread is located by using the existing flaring method or stamping method, and make the external thread on the outer surface of the part body 1 produce local convex deformation 6 through the concave deformation pit 3, Deformed as figure 2 shown by figure 2 It can be seen that the tooth height of the external thread is raised upwards by δ from the original height (shown by the dotted line in the figure). Due to the local convex deformation on the thread, a self-locking moment will be generated during connection; the twelve-point spline hole has the effect of preventing rotation. In order to facilitate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com