A method for efficiently making paper using polyester fibers

A polyester fiber, high-efficiency technology, applied in papermaking, fiber processing, fiber type and other directions, can solve the problems of low papermaking efficiency, poor dispersion performance, insufficient bonding strength between fibers and matrix materials, etc., to improve papermaking efficiency, improve The effect of paper body properties, good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

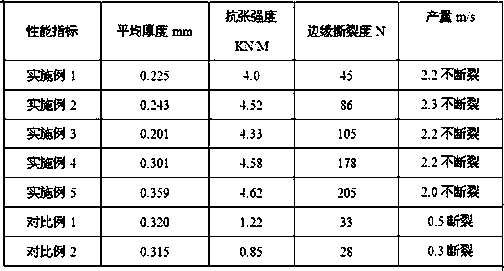

Examples

Embodiment 1

[0028] (1) The polyester fiber with a length of 5mm is treated with low-temperature plasma first. The low-temperature plasma treatment process uses a reactive gas source, setting the discharge time to 180s, the discharge power to 200W, the flow rate of the reactive gas to 100sccm, and the plasma discharge pressure to 0.1Pa , and then carry out the liquid phase grafting treatment, the liquid phase grafting treatment is that the polyester fiber after the low-temperature plasma treatment is put into the reaction bottle for grafting, and the reaction solution is a solution with a concentration of 5% by volume of allylamine, The grafting temperature is 65°C, the grafting time is 2 hours, and after drying and washing, the polyester fiber with allylamine grafted on the surface is obtained;

[0029] (2) Weigh 50 parts by weight of polyester fibers grafted with allylamine on the surface, 49 parts by weight of coniferous wood pulp fibers, and 1 part by weight of sodium polyphosphate to m...

Embodiment 2

[0035] (1) The polyester fiber with a length of 12mm is treated with low-temperature plasma first. The low-temperature plasma treatment process uses a reactive gas source, and the discharge time is set to 200s, the discharge power is 160W, the flow rate of the reactive gas is 100sccm, and the plasma discharge pressure is 1Pa , and then carry out the liquid phase grafting treatment, the liquid phase grafting treatment is that the polyester fiber after the low-temperature plasma treatment is put into the reaction bottle for grafting, and the reaction solution is a solution of 6.5% concentration of allylamine by volume, The grafting temperature is 55°C, the grafting time is 4 hours, and after drying and washing, the polyester fiber with allylamine grafted on the surface is obtained;

[0036] (2) Weigh polyester fibers with a mass fraction of 70% grafted with allylamine on the surface, bamboo fibers with 10 parts by weight, and gum mixture with 2 parts by weight, add an appropriate...

Embodiment 3

[0042](1) The polyester fiber with a length of 25mm is treated with low-temperature plasma first. The low-temperature plasma treatment process uses a reactive gas source, and the discharge time is set to 250s, the discharge power is 200W, the flow rate of the reactive gas is 100sccm, and the plasma discharge pressure is 10Pa , and then carry out the liquid phase grafting treatment, the liquid phase grafting treatment is to put the polyester fiber after the low-temperature plasma treatment into the reaction bottle for grafting, and the reaction solution is allylamine with a concentration of 5-10% by volume. solution, the grafting temperature is 65°C, the grafting time is 3 hours, after drying and washing, the polyester fiber with allylamine grafted on the surface is obtained;

[0043] (2) Weighing 60 parts by weight of polyester fiber grafted with allylamine on the surface, 25 parts by weight of wheat straw fiber, and 5 parts by weight of talcum powder, adding an appropriate amo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com