Anodic oxidation nickel-free hole sealing agent

An anodic oxidation and nickel sealing technology, which is applied in the field of anodic oxidation nickel-free sealing agent, can solve the problems of low sealing agent sealing efficiency and environmental pollution, and achieve fast sealing speed, smooth and clean surface, and improved efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

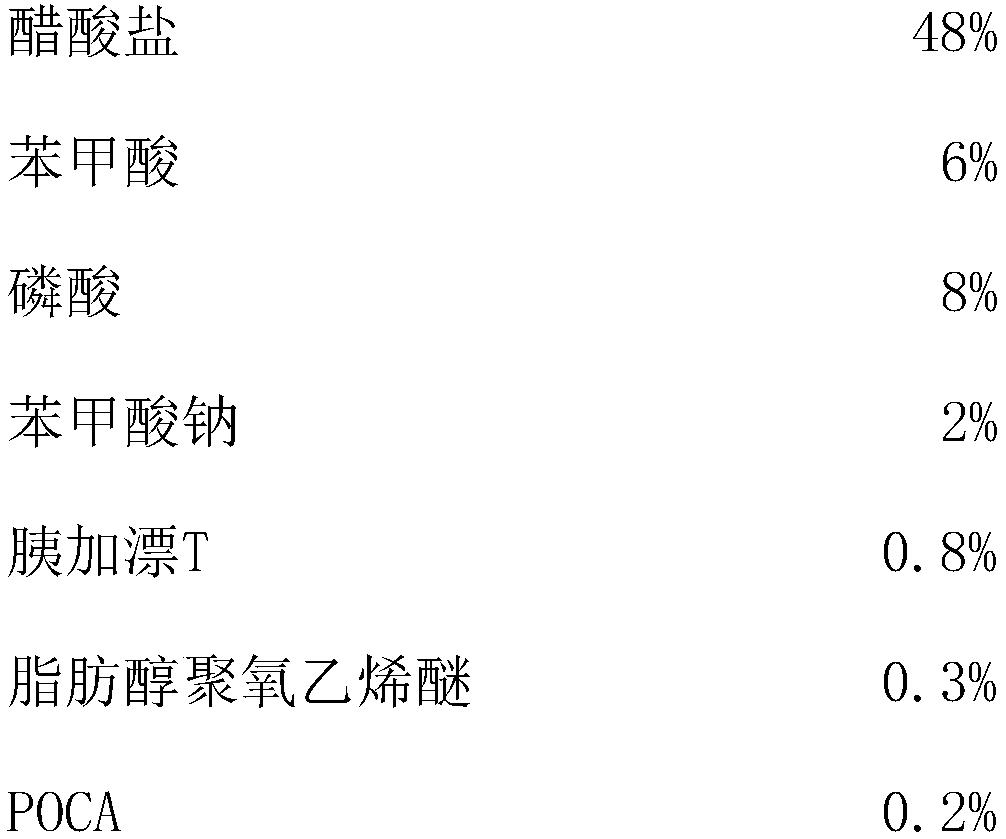

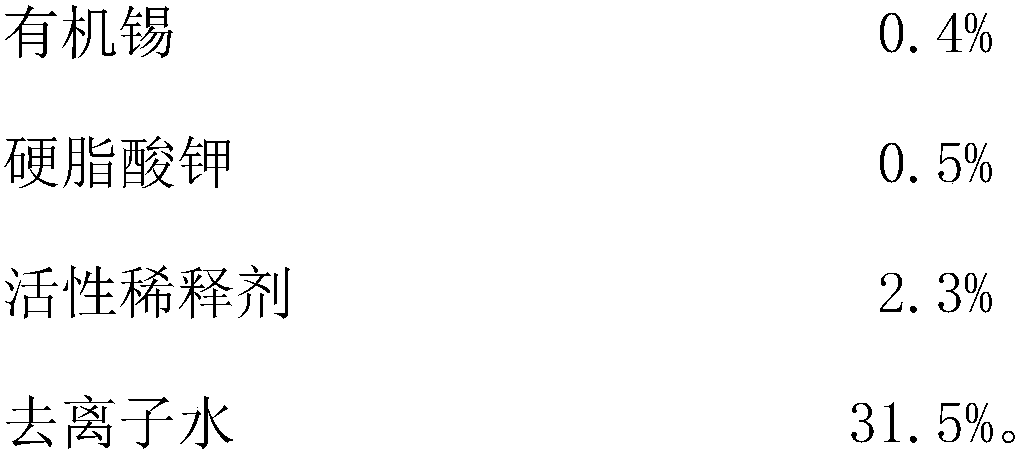

[0017] An anodic oxidation nickel-free sealing agent, comprising by mass percentage

[0018]

[0019] Wherein, acetate is the mixture of ammonium acetate and cobalt acetate.

[0020] Organotin is dimethyltin.

[0021] The reactive diluent is HK-66.

Embodiment 2

[0023] An anodic oxidation nickel-free sealing agent, comprising by mass percentage

[0024]

[0025]

[0026] Wherein, acetate is the mixture of sodium acetate and potassium acetate.

[0027] Organotin is tetraphenyltin.

[0028] The reactive diluent is HELOXY505.

Embodiment 3

[0030] An anodic oxidation nickel-free sealing agent, comprising by mass percentage

[0031]

[0032]

[0033] Wherein, acetate is the mixture of calcium acetate and magnesium acetate.

[0034] Organotin is dioctyltin.

[0035] The reactive diluent is HELOXY48.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com