Carbon dioxide automatic control recycling device for fermentation tank

A recovery device and technology for carbon dioxide, applied in the field of carbon dioxide automatic control recovery device, can solve the problems of low energy consumption, high labor cost, low separation effect, etc., and achieve the effects of reducing CO2 emissions, improving the environment, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

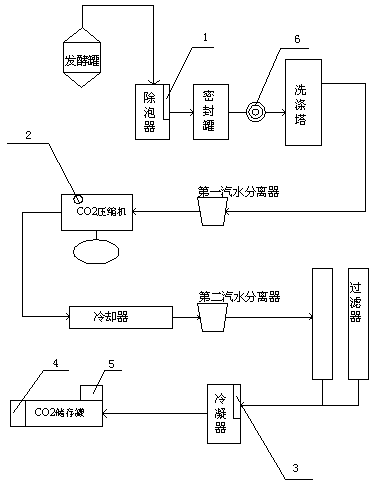

[0020] like figure 1 , figure 2 As shown, a carbon dioxide automatic control recovery device for a fermenter includes a recovery device and an automatic control device;

[0021] The recovery unit includes a bubble remover, a sealed tank, a washing tower, a first steam-water separator, a CO 2 Compressor, cooler, second separator, filter, condenser, CO 2 storage tank, the gas inlet of the debubbler and the CO of the fermenter 2 The gas outlet of the sealed tank is connected with the gas outlet of the scrubber, the gas outlet of the scrubber is connected with the inlet of the first steam-water separator, and the gas outlet of the first steam-water separator is connected with the gas outlet of the scrubber. CO 2 Compressor inlet connection, CO 2 The outlet of the compressor is connected to the cooler, the outlet of the cooler is connected to the second steam-water separator, the gas outlet of the second steam-water separator is connected to the inlet of the filter, the outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com