Machining fine positioning pin positioning protection device

A protection device and machining technology, applied in the field of machining, can solve the problems of reduced precision positioning pin positioning accuracy, fine positioning pin damage, affecting the movement continuity of precision positioning pin positioning accuracy, etc., to avoid the influence of positioning accuracy, structure Simple, less bumpy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

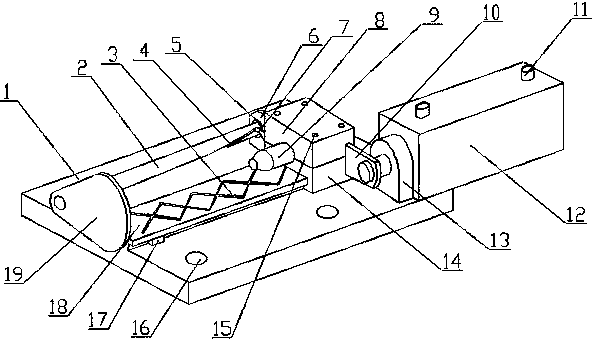

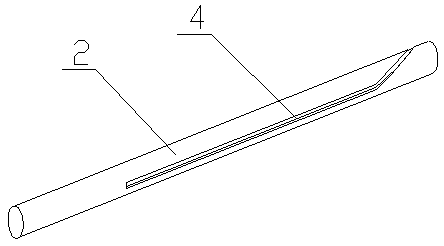

[0021] A machined fine positioning pin positioning protection device of the present invention is realized in this way. When in use, when finishing machining a machined product, first fix the base (1) in an appropriate position through the mounting hole (16), and then place the product Place the positioning pin on the other side of the protective plate (19), and connect the two connectors (11) on the cylinder (12) to the external air pipe respectively. When the product needs to be supported and fixed, the cylinder (12) will work. The telescopic rod on the cylinder (12) performs a stretching movement, and drives the sliding base (14) to move through the connecting plate (10), and the sliding base (14) moves to one end of the sliding rail (18) along the sliding rail (18), and the sliding base (14) Drive the fine positioning pin (9) to move to one end of the sliding rail (18) through the fixed cover plate (8), and the sliding base (14) drives the transmission lever (7) to move, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com