Preparation method and application of a CD/CDS heterojunction visible photocatalyst rich in sulfur vacancies

A photocatalyst and heterojunction technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of inability to flexibly adjust the morphology of CdS matrix sulfur vacancies, and difficult to achieve CdS light absorption and light absorption. Catalytic properties, limiting the application of CdS photocatalysts, etc., to achieve excellent visible light photocatalytic performance, high light absorption and visible light catalytic efficiency, and the effect of close contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] Preparation of CdS precursor:

[0024] Add cadmium nitrate tetrahydrate and thiourea into a polytetrafluoroethylene reactor at a molar ratio of 1:3, add ethylenediamine to 60% of the volume of the reactor, stir magnetically until completely dissolved, and react at 200°C for 24 hours , the resulting product was naturally cooled to room temperature, washed four times with deionized water and ethanol respectively, the precipitate was collected by centrifugation, and dried in vacuum to obtain the CdS precursor.

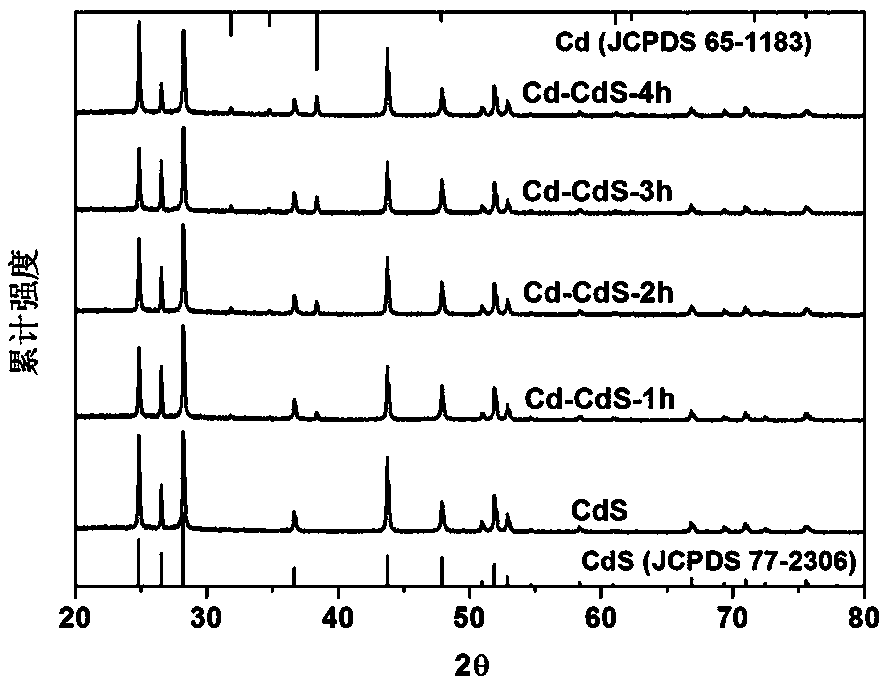

Embodiment 1

[0026] Put 500mg of the prepared CdS in a muffle furnace for heat treatment at 400°C for 1h to obtain the intermediate CdO / CdS composite material, slowly add it to 50mL 1mol / L NaBH 4 solution, stirred at room temperature for 4 hours, filtered, washed and dried to obtain a Cd / CdS heterojunction visible photocatalyst rich in sulfur vacancies, labeled as Cd-CdS-1h.

Embodiment 2

[0028] Put 500mg of the prepared CdS in a muffle furnace for heat treatment at 400°C for 2h to obtain the intermediate CdO / CdS composite material, slowly add it to 50mL 1mol / L NaBH 4 solution, stirred at room temperature for 4 hours, filtered, washed and dried to obtain a Cd / CdS heterojunction visible photocatalyst rich in sulfur vacancies, labeled as Cd-CdS-2h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com