Method for preparing nanorod-shaped high bismuth oxyiodide photocatalyst

A photocatalyst and nanorod-like technology, applied in the field of materials science, can solve the problems of difficult control of the reaction process, high production cost, energy consumption, etc., and achieve the effects of good photocatalytic performance, short reaction time and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) 0.97g of Bi(NO 3 ) 3 ·5H 2 O was added to a beaker containing 10ml of ethanol, and ultrasonicated at 100Hz for 10 minutes to obtain suspension A.

[0030] (2) Dissolve 0.332 g of KI in 20 ml of deionized water to obtain solution B, slowly add solution B to the above suspension A, and react with magnetic stirring for 15 minutes to obtain suspension C.

[0031] (3) Dissolve 8 g of NaOH in 50 ml of deionized water to obtain a 4 mol / L NaOH solution.

[0032] (4) Slowly add the above-mentioned NaOH solution dropwise into the magnetically stirred suspension C, stop adding the NaOH solution when the pH of the suspension C measured by a pH gun is 14, then stir at room temperature for 2 hours, and collect the precipitate by centrifugation The material was washed three times with deionized water and absolute ethanol, and dried at 80°C for 8 hours to obtain rod-shaped Bi 5 o 7 I.

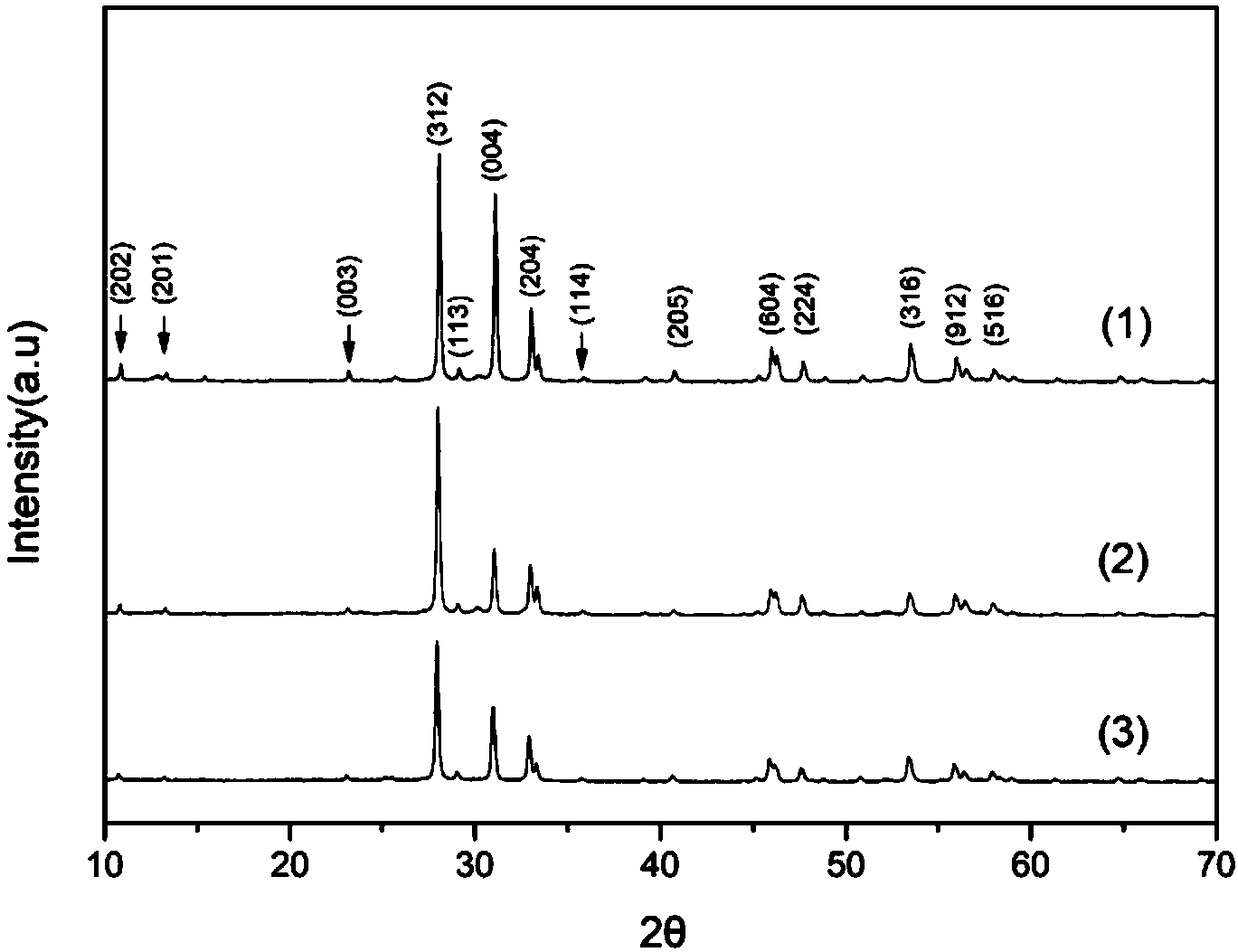

[0033] (5) For the synthesized rod-shaped Bi 5 o 7 I carry out X-ray diffraction analysi...

Embodiment 2

[0035] (1) 0.97g of Bi(NO 3 ) 3 ·5H 2 O was added to a beaker containing 10ml of deionized water, and ultrasonicated at 80HZ for 15 minutes to obtain suspension A.

[0036] (2) Dissolve 0.332 g of KI in 20 ml of deionized water to obtain solution B, slowly add solution B to the above suspension A, and react with magnetic stirring for 15 minutes to obtain suspension C.

[0037](3) Dissolve 8 g of NaOH in 50 ml of deionized water to obtain a 4 mol / L NaOH solution.

[0038] (4) Slowly add the above-mentioned NaOH solution dropwise into the magnetically stirred suspension C, stop adding the NaOH solution when the pH of the suspension C measured by a pH gun is 13, then stir at room temperature for 2 hours, and collect the precipitate by centrifugation The material was washed three times with deionized water and absolute ethanol, and dried at 80°C for 8 hours to obtain rod-shaped Bi 5 o 7 I.

[0039] (5) For the synthesized rod-like Bi 5 o 7 I carry out X-ray diffraction ana...

Embodiment 3

[0041] (1) 0.97g of Bi(NO 3 ) 3 ·5H 2 O was added to a beaker containing 20ml of ethanol, and ultrasonicated at 100HZ for 10 minutes to obtain suspension A.

[0042] (2) Dissolve 0.332 g of KI in 20 ml of deionized water to obtain solution B, slowly add solution B to the above suspension A, and react with magnetic stirring for 15 minutes to obtain suspension C.

[0043] (3) Dissolve 4 g of NaOH in 50 ml of deionized water to obtain a 2 mol / L NaOH solution.

[0044] (4) Slowly add the above-mentioned NaOH solution dropwise into the magnetically stirred suspension C, stop adding the NaOH solution when the pH of the suspension C measured by a pH gun is 13, then stir at room temperature for 2 hours, and collect the precipitate by centrifugation The material was washed three times with deionized water and absolute ethanol, and dried at 80°C for 8 hours to obtain rod-shaped Bi 5 o 7 I.

[0045] (5) For the synthesized rod-like Bi 5 o 7 I carry out X-ray diffraction analysis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com