Liquid taking control method and device, and liquid taking system

A control method and control device technology, applied in the detection field, can solve problems such as erroneous experimental results, hardware manufacturing process deviation, and inability to absorb reagents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

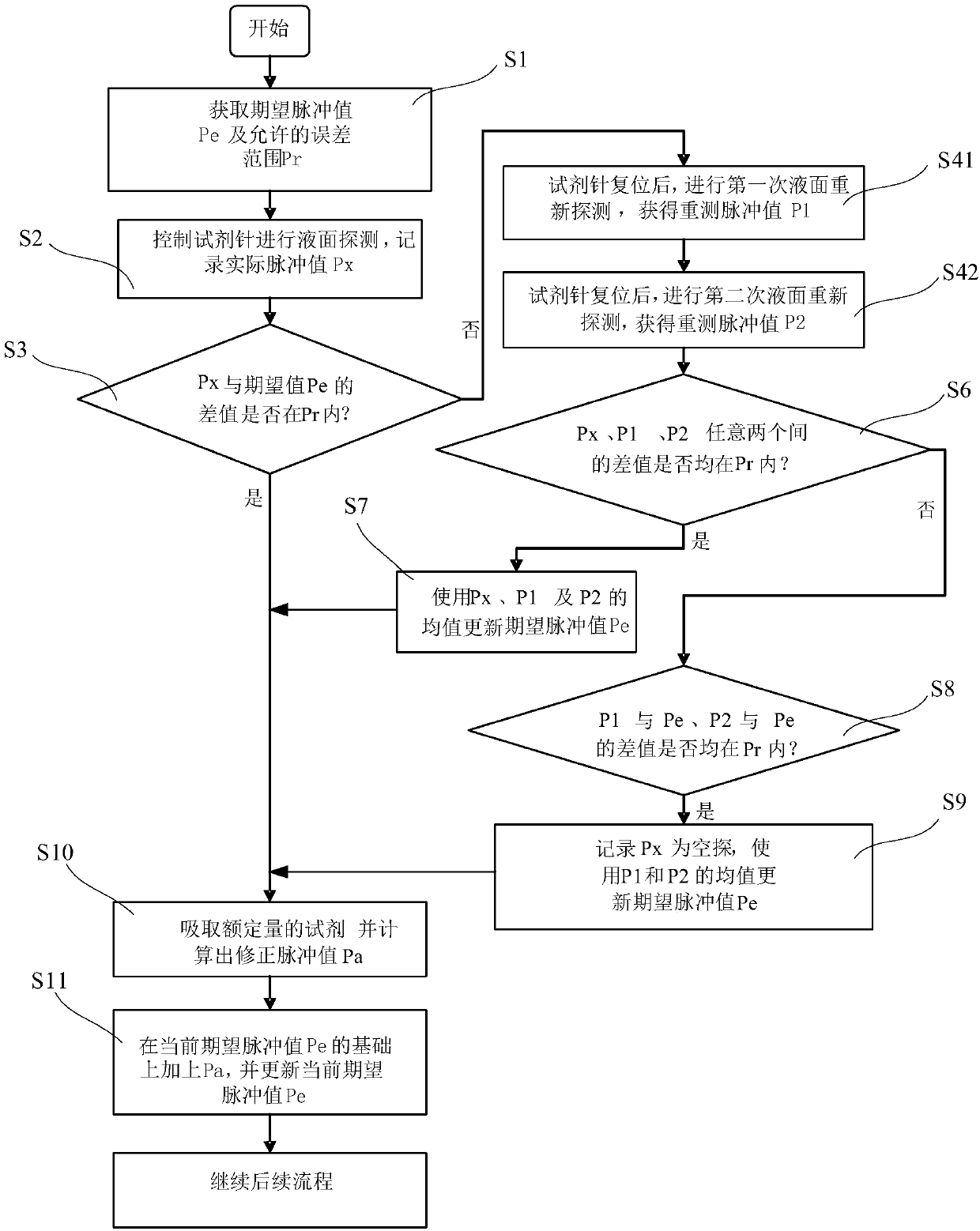

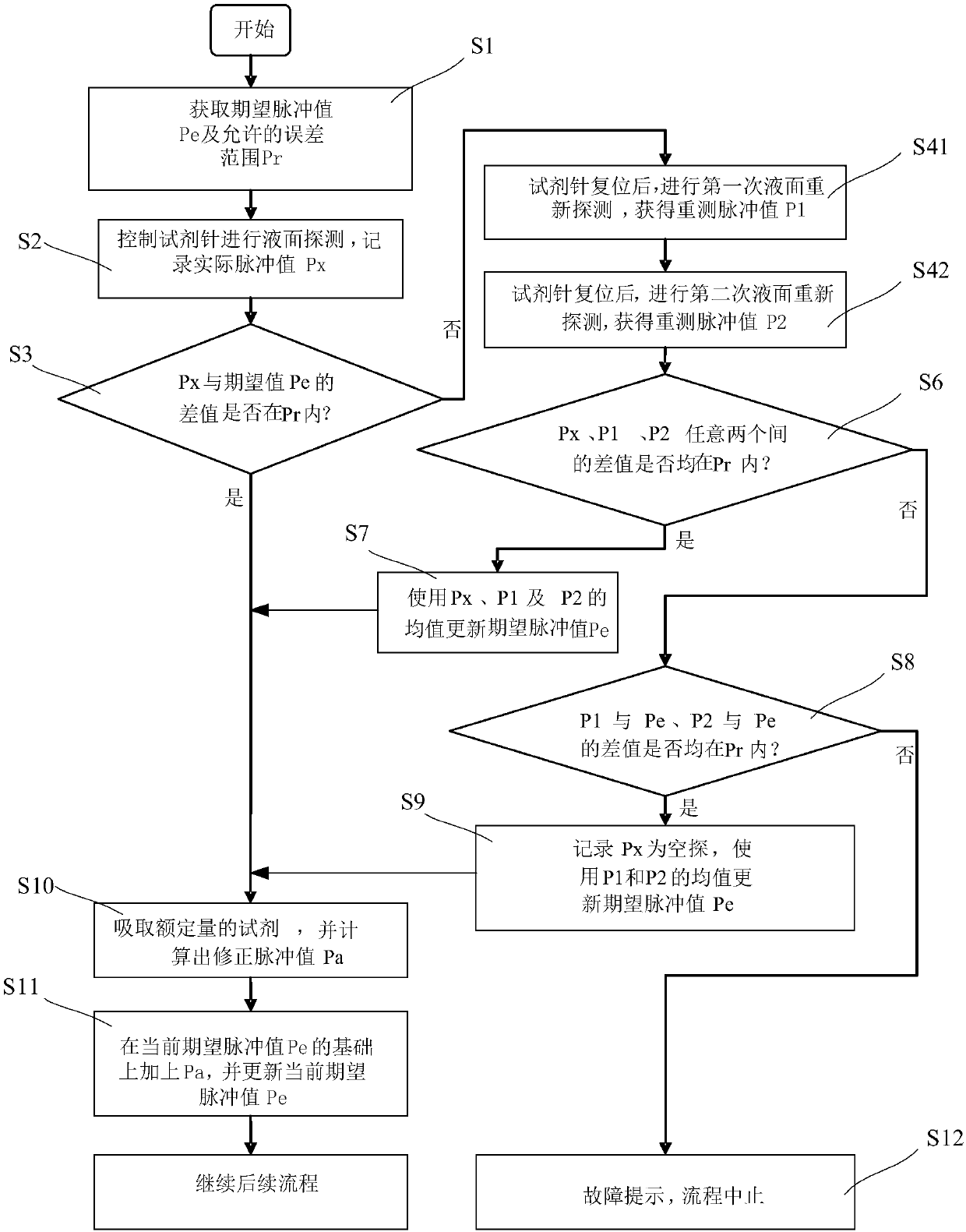

[0046] How to effectively prevent the occurrence of the air detection phenomenon when absorbing the reagent from the reagent container is a technical problem that those skilled in the art, including the inventor, have always expected to solve.

[0047] Before the creation of the present invention, the inventor once focused on improving the angle of the liquid level sensor, because the liquid level sensor is arranged on the reagent needle, and when the reagent needle touches the liquid surface, the feedback signal of the liquid level sensor will be In case of a sudden change, in order to prevent empty detection or misjudgment, the type of liquid level sensor can be replaced, such as capacitive liquid level sensor, infrared liquid level sensor or ultrasonic liquid level sensor. However, the inventors found after the analysis and research of the results that the scheme formed under this kind of thinking has not effectively solved the generation of the air detection phenomenon, bec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com