Fully-automatic intelligent sample preparation system and method

A sample preparation system, fully automatic technology, applied in the preparation of test samples, weighing by removing certain components, etc., to avoid cross-contamination, improve the level of intelligence and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

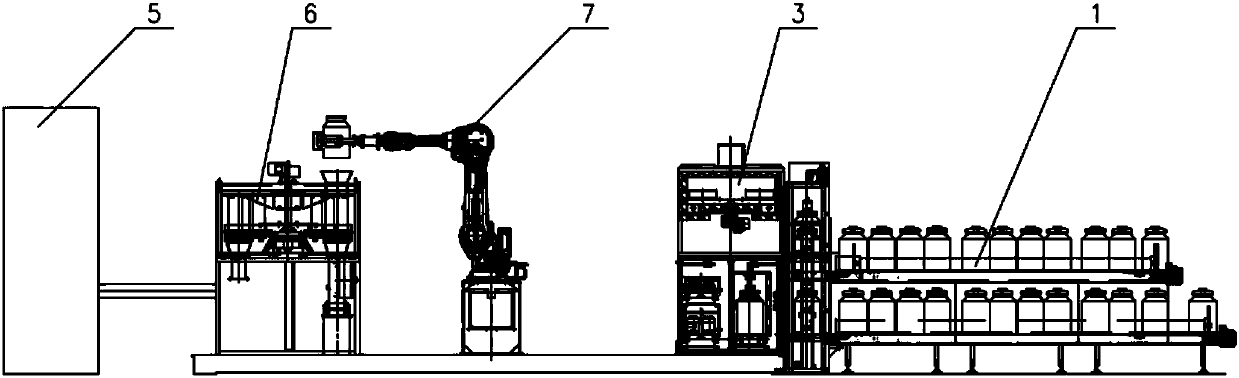

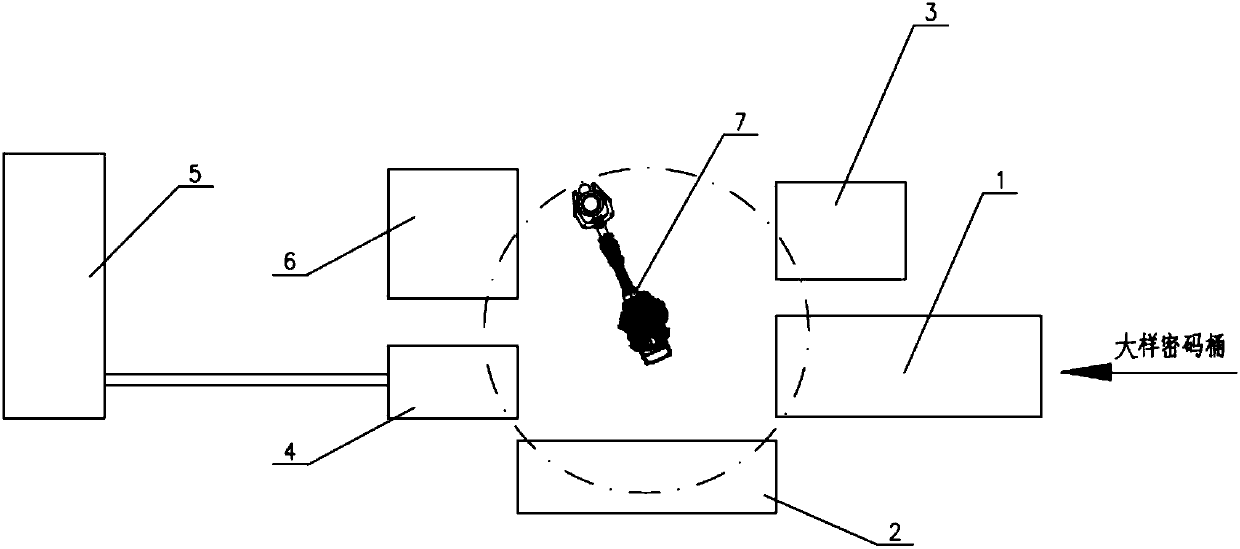

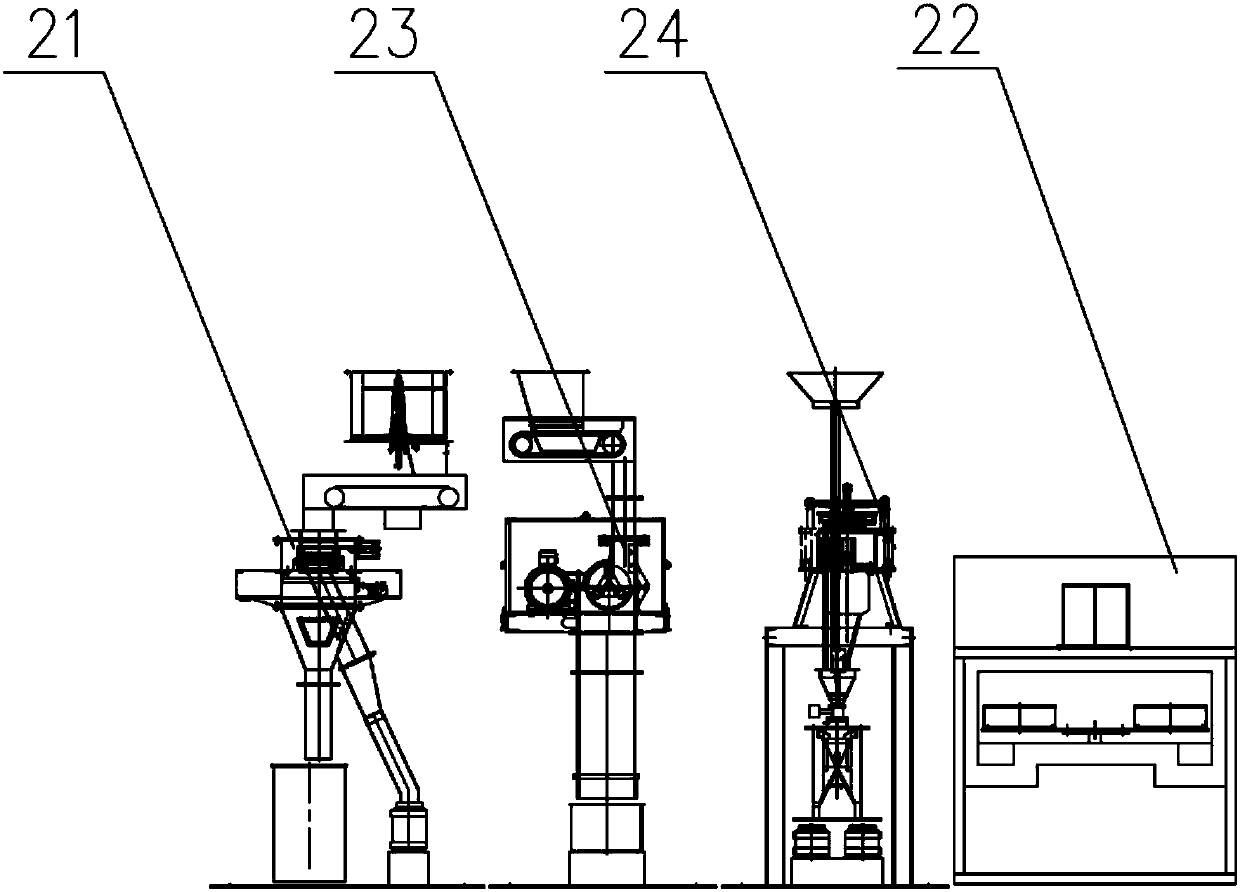

[0034] Such as Figure 1-4 Shown is a fully automatic intelligent sample preparation system implemented according to the present invention, including: large sample buffer transport module 1, thermal coal sample preparation module 2, total moisture analysis module 3, sample bottle packaging module 4, sample bottle delivery and storage module 5 , Abandoned Sample Temporary Storage Module 6, Industrial Robot 7. Samples are transferred between the modules by an industrial robot 7 . The following is a detailed description of the six modules in turn.

[0035] like figure 1 and 2 , Large sample buffer conveying module 1, including chain plate conveyor and password bucket elevator. Large samples collected and processed to -6mm in the sampling link are sent to the intelligent automatic sample preparation system for sample preparation. The large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com