Compound-type gas sampling pipe for coal spontaneous combustion detection in goaf and preparation method of pipe

A technology for detecting gas and gobs, applied to pipes, rigid pipes, mechanical equipment, etc., can solve problems such as rock crushing, sparks, and corrosion, and achieve large production volume, low production cost, and high demand big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

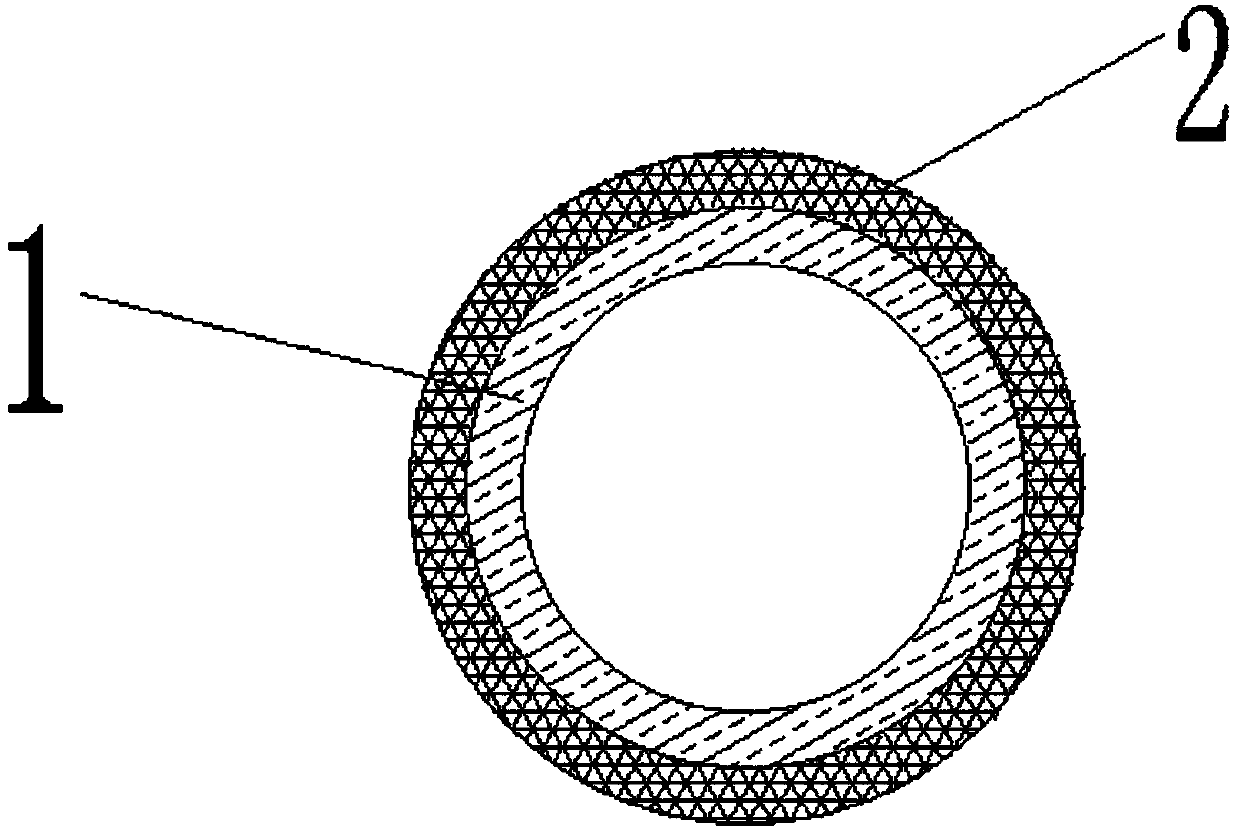

[0013] like figure 1 As shown, a composite goaf coal spontaneous combustion detection gas sampling pipeline includes an austenitic stainless steel inner casing 1 and a hard outer casing 2, and the hard outer casing 2 is overlaid on the austenitic stainless steel inner casing 1 The outer surface. The material of the hard outer sleeve 2 is PVC or PE with antistatic agent added. The inner casing 1 is formed by austenitic stainless steel, and the outer casing 2 is formed by melting and wrapping the outer surface of the austenitic stainless steel of the inner casing by adding antistatic agent PE or PVC hard pipe material. In this way, the austenitic stainless steel inner casing 1 and the PE or PVC material outer casing 2 added with an antistatic agent have become a whole. The austenitic stainless steel inner casing 1 does not produce ethylene or aromatic gases during use, which does not affect the indicator gases used as coal spontaneous combustion detection: carbon monoxide, eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com