Method for preparing high-transparency copying paper by applying waste-paper deinked pulp

A technology for deinking pulp and high transparency of waste paper, applied in the field of papermaking, can solve the problems of poor transparency, poor mechanical properties, and poor deinking effect of copy paper, and achieve the effects of good mechanical properties, improved leveling and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

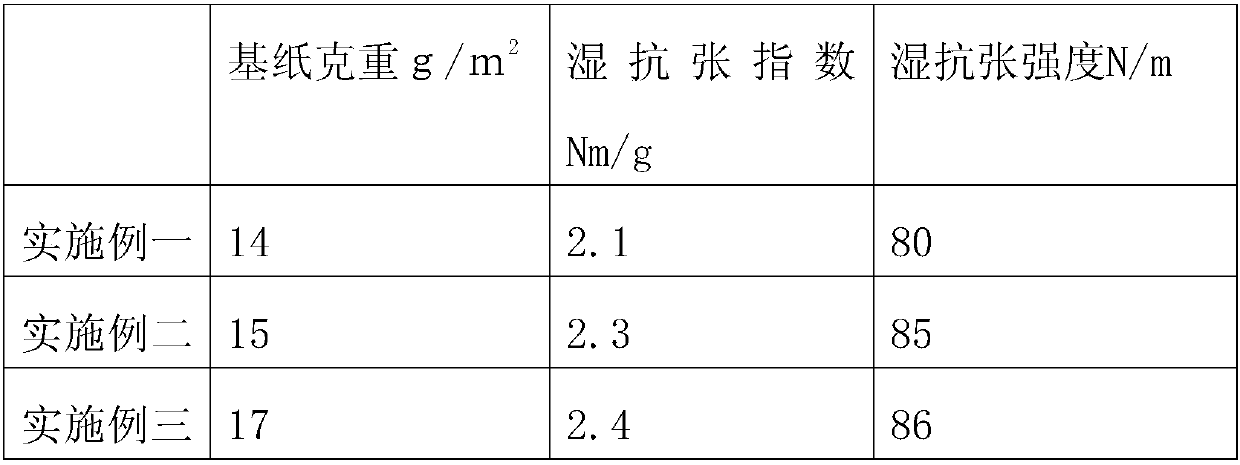

Examples

Embodiment 1

[0017] A method for preparing high-transparency copy paper by using waste paper deinking pulp, comprising the following processing steps:

[0018] (1) Collect waste paper pulp, add modified deinking agent to deink it, the deinking agent of described modification is made up of each raw material of following parts by weight: 20 parts of sodium dodecylsulfonate, polyoxyethylene alkanes 10 parts of base ether, 20 parts of propylene glycol, 40 parts of sodium hydroxide, 10 parts of dimethyl diallyl ammonium chloride, 5 parts of methacrylamide, 3 parts of EDTA, 10 parts of pentaerythritol tetraacrylate; Controlled at 75°C, deinking treatment for 30 minutes, the amount of deinking agent is 3% of the waste paper pulp weight, to obtain deinked pulp;

[0019] (2) add sodium borohydride, diethyltriaminepentaacetic acid to the deinked pulp obtained through step (1), and wash; the consumption of sodium borohydride and diethyltriaminepentaacetic acid is the deinked pulp weight 10wt%, 4wt%;...

Embodiment 2

[0024] A method for preparing high-transparency copy paper by using waste paper deinking pulp, comprising the following processing steps:

[0025] (1) Collect waste paper pulp, add modified deinking agent to deink it, the deinking agent of described modification is made up of each raw material of following parts by weight: 30 parts of sodium dodecylsulfonate, polyoxyethylene alkanes 13 parts of base ether, 25 parts of propylene glycol, 45 parts of sodium hydroxide, 12 parts of dimethyl diallyl ammonium chloride, 8 parts of methacrylamide, 4 parts of EDTA, 15 parts of pentaerythritol tetraacrylate; Controlled at 80°C, deinking treatment for 45 minutes, the amount of deinking agent is 5% of the weight of waste paper pulp, to obtain deinked pulp;

[0026] (2) add sodium borohydride, diethyltriaminepentaacetic acid to the deinked pulp obtained through step (1), and wash; the consumption of sodium borohydride and diethyltriaminepentaacetic acid is the deinked pulp weight 13wt%, 6w...

Embodiment 3

[0031] A method for preparing high-transparency copy paper by using waste paper deinking pulp, comprising the following processing steps:

[0032] (1) Collect waste paper pulp, add modified deinking agent to deink it, the deinking agent of described modification is made up of each raw material of following parts by weight: 40 parts of sodium dodecylsulfonate, polyoxyethylene alkanes 16 parts of base ether, 30 parts of propylene glycol, 50 parts of sodium hydroxide, 15 parts of dimethyl diallyl ammonium chloride, 10 parts of methacrylamide, 5 parts of EDTA, 20 parts of pentaerythritol tetraacrylate; Controlled at 85°C, deinking treatment for 60 minutes, the amount of deinking agent is 8% of the waste paper pulp weight, to obtain deinked pulp;

[0033] (2) add sodium borohydride, diethyltriaminepentaacetic acid to the deinked pulp obtained through step (1), and wash; the consumption of sodium borohydride and diethyltriaminepentaacetic acid is the deinked pulp weight 15wt%, 8wt%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com