Copper sulfate electroplating solution and preparation method and application thereof and electrolytic cell

A technology of electrolytic cell and electroplating solution, applied in the direction of electrolysis process, electrolysis components, circuits, etc., can solve the problems of high raw material quality requirements, long process route, high production cost, etc., achieve good industrial application value, simple production process, and reliable quality reliable effect

Active Publication Date: 2018-01-30

SHANGHAI SINYANG SEMICON MATERIALS

View PDF7 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method has a long process route and high requirements on the quality of raw materials, and the fluctuation of the metal impurity content in the raw materials cannot be controlled. After the reaction, it is necessary to remove H 2 o 2 or HNO 3 , there is waste gas and wastewater discharge, pollutes the environment, and the production cost is high. For the line width design below 65nm, it is difficult to guarantee reliability

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

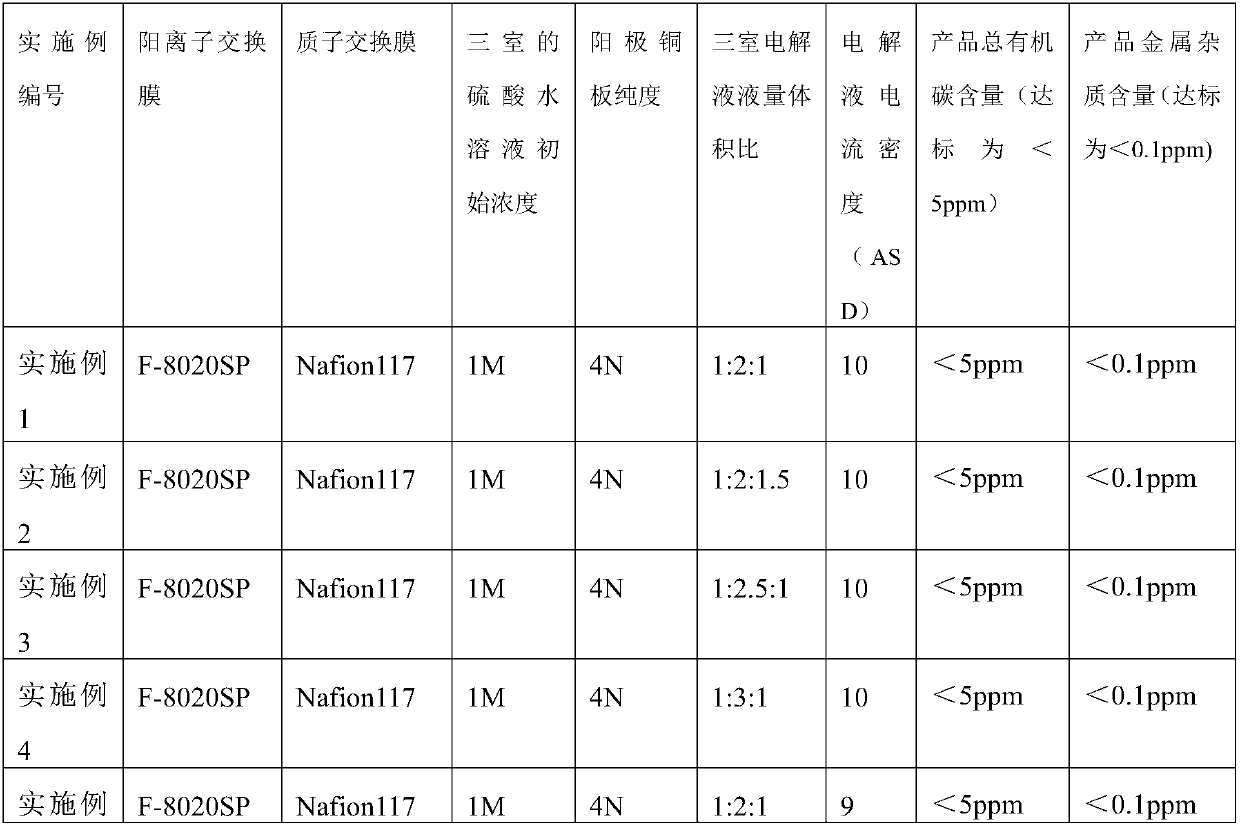

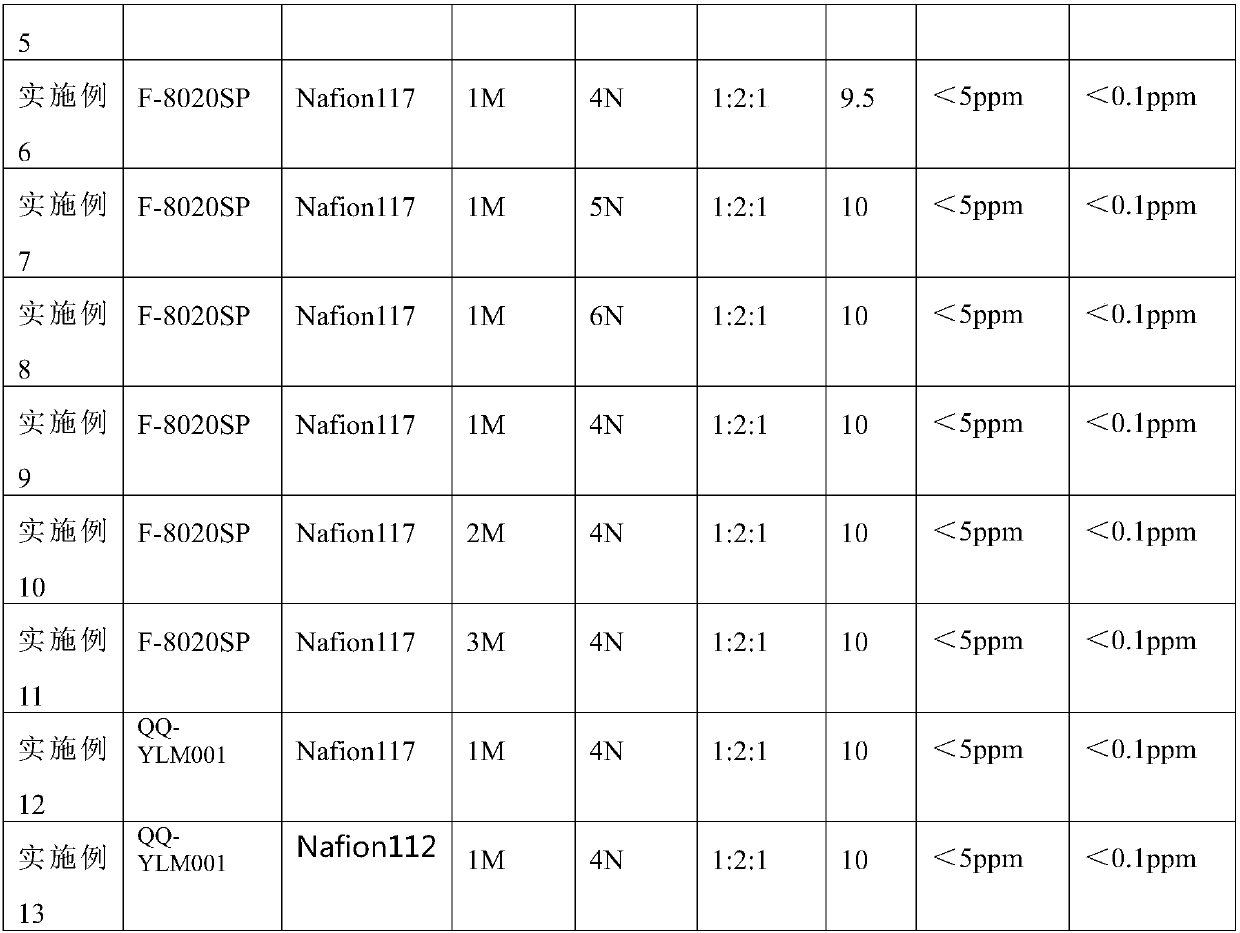

Embodiment 1-13

[0075] The preparation of embodiment 1-13 copper sulfate electroplating solution 1-13

[0076] In the present invention, the preparation conditions of copper sulfate electroplating solution 1-13 are as shown in Table 1.

[0077] Table 1

[0078]

[0079]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

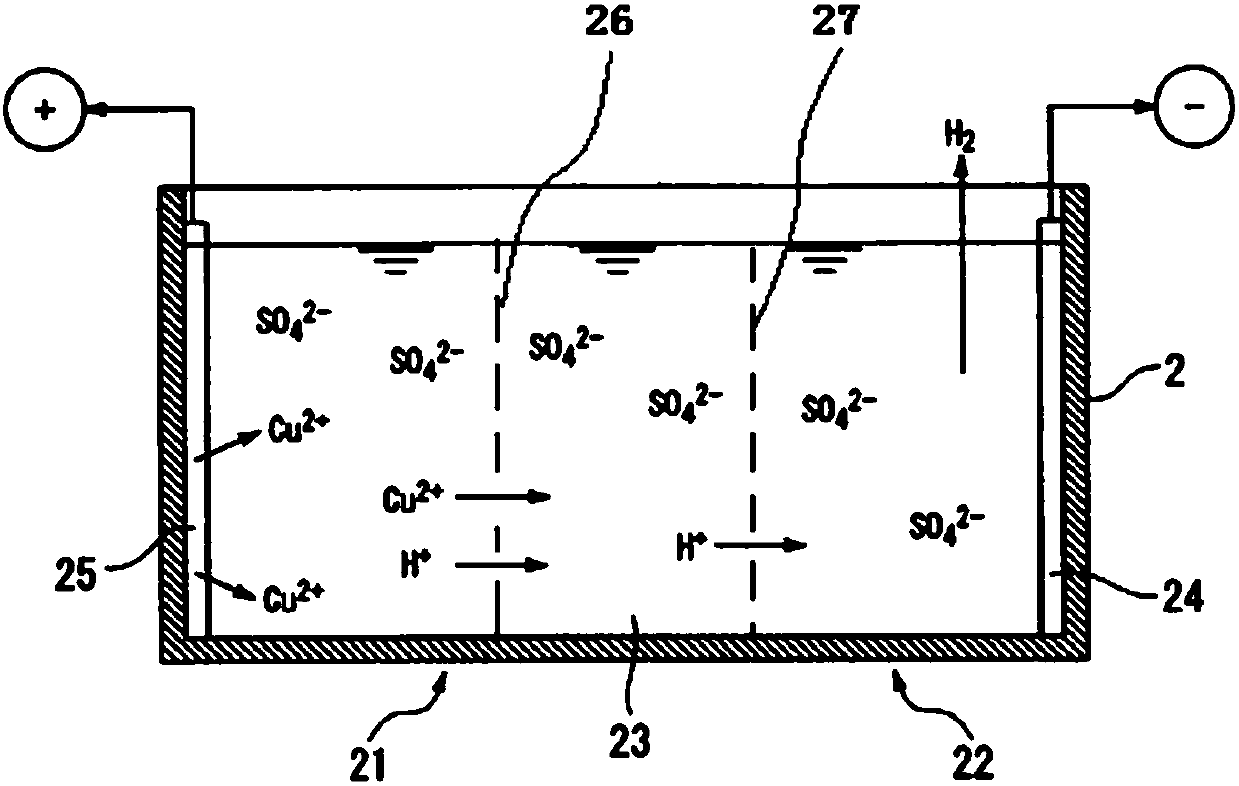

The invention discloses a copper sulfate electroplating solution and a preparation method and application thereof and an electrolytic cell. The preparation method includes: performing electrolytic reaction in the electrolytic cell, wherein electrolyte for electrolysis is a sulfuric acid aqueous solution which is 1mol / L-3mol / L, and current density of the electrolyte is 9-10ASD; arranging an anode,a cathode, a cation exchange membrane and a proton exchange membrane are arranged in the electrolytic cell. The preparation method is free from a traditional evaporation-recrystallization chemical process, free from discharge of waste gas and wastewater, environment friendly and simple in production process, and the copper sulfate electroplating solution prepared is high in purity, controllable and reliable in quality and applicable to copper interconnecting plating in fields of semiconductor manufacturing and packaging.

Description

technical field [0001] The invention relates to a copper sulfate electroplating solution, its preparation method and application and an electrolytic tank. Background technique [0002] At present, in the integrated circuit process, Damascus copper interconnection technology is widely used. Copper deposition technology is the key technology in Damascus copper interconnection technology. Whether the copper deposited in the micro-groove (hole) is dense, whether there are voids or cracks, directly affects the copper. The resistivity and anti-migration performance of the interconnection wire, and the key semiconductor material to realize the Damascus copper interconnection technology is the high-purity copper sulfate electroplating solution. The purity index of this product is very high, otherwise the reliability of the copper wiring will be affected. At present, most of the methods for producing ultra-clean and high-purity copper interconnect copper sulfate electroplating soluti...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C25D3/38C25D7/12C25B1/00C25B9/08C25B9/19

Inventor 王溯张怡

Owner SHANGHAI SINYANG SEMICON MATERIALS

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com