Hylocereus undulatus britt fructus wine and preparation method thereof

A technology of pitaya wine and pitaya, applied in the field of wine production, can solve the problems of insufficient anthocyanin content, decreased sweetness of finished wine, decreased quality of finished wine, etc., so as to solve the problem of decreased sweetness of finished wine and smooth taste , the effect of increasing the sweetness of the wine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

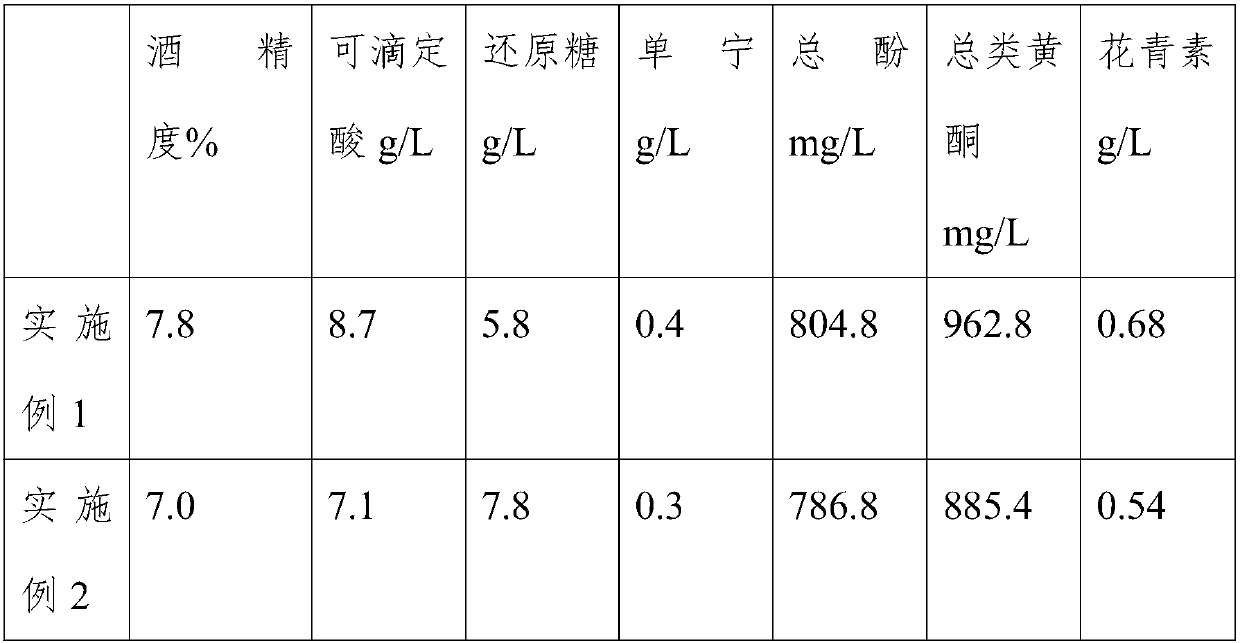

Embodiment 1

[0029] A kind of dragon fruit wine manufacture method:

[0030] (1) raw material selection: select fully mature, no rot and mildew, 100kg of fresh dragon fruit without worms as raw material;

[0031] (2) Fruit treatment: wash the dragon fruit to remove the floating soil and other impurities on the surface, and remove the dry epidermis and scars;

[0032] (3) beating: crushing the cleaned pitaya with skin into pulp;

[0033] (4) Enzymolysis: add 4.5% pectinase to the pulp, heat in an ultrasonic water bath at 48°C for 3.5 hours;

[0034] (5) Enzyme inactivation: after enzymolysis, heat the pulp at 95°C for 12.5 minutes;

[0035] (6) Initial fermentation: add the fruit pulp after enzymolysis into the fermenter, and add yeast with a weight of 2.0% of the pulp to the fermenter for fermentation. The fermentation temperature is 21-23 ° C, and the fermentation is stopped after 20 days to obtain a fermented liquid;

[0036] (7) liquid slag separation: the fermented liquid is separa...

Embodiment 2

[0043] A kind of dragon fruit wine manufacture method:

[0044] (1) raw material selection: select fully mature, no rot and mildew, 100kg of fresh dragon fruit without worms as raw material;

[0045] (2) Fruit treatment: wash the dragon fruit to remove the floating soil and other impurities on the surface, and remove the dry epidermis and scars;

[0046] (3) beating: crushing the cleaned pitaya with skin into pulp;

[0047] (4) Enzymolysis: add 4% pectinase according to the weight of the pulp, and heat in an ultrasonic water bath at 47°C for 3 hours;

[0048] (5) Enzyme inactivation: after enzymolysis, heat the pulp at 90°C for 10 minutes;

[0049] (6) Initial fermentation: add the enzymatically hydrolyzed fruit pulp into a fermenter, and add yeast with a weight of 1.5% of the pulp to the fermenter for fermentation. The fermentation temperature is 21-23°C, and the fermentation is stopped after 17 days to obtain a fermented liquid;

[0050] (7) liquid slag separation: the f...

Embodiment 3

[0056] A kind of dragon fruit wine manufacture method:

[0057] (1) raw material selection: select fully mature, no rot and mildew, 100kg of fresh dragon fruit without worms as raw material;

[0058] (2) Fruit treatment: wash the dragon fruit to remove the floating soil and other impurities on the surface, and remove the dry epidermis and scars;

[0059] (3) beating: crushing the cleaned dragon fruit with skin into pulp;

[0060] (4) Enzymolysis: add 5% pectinase according to the weight of the pulp, and heat in an ultrasonic water bath at 49°C for 4 hours;

[0061] (5) Enzyme inactivation: after enzymolysis, heat the pulp at 100°C for 15 minutes;

[0062] (6) Initial fermentation: add yeast accounting for 2.3% of the mass of thorn grapes in the fermenter to ferment at a fermentation temperature of 21-23°C, stop fermentation after 21 days of fermentation, and obtain a fermented liquid;

[0063] (7) liquid slag separation: the fermented liquid is separated by pressing method to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com