Method for pretreating canned citrus petal production wastewater and recycling pectin simultaneously

A technology for production wastewater and pretreatment, which is applied in the food industry wastewater treatment, water/sewage treatment, chemical instruments and methods, etc. Effects of CODCr

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] The pretreatment of canned citrus production waste water of the present invention and the method for simultaneously reclaiming pectin are as follows:

[0023] 1. Filtration: The acid-base cleaning wastewater in the front part of the canned citrus production process is removed through the grid to remove solid debris above 5mm, so as not to block or damage the equipment in the subsequent section;

[0024] 2. Wastewater adjustment: adjust the pH of the wastewater to 2, add 1mg / L of CaCl 2 ;

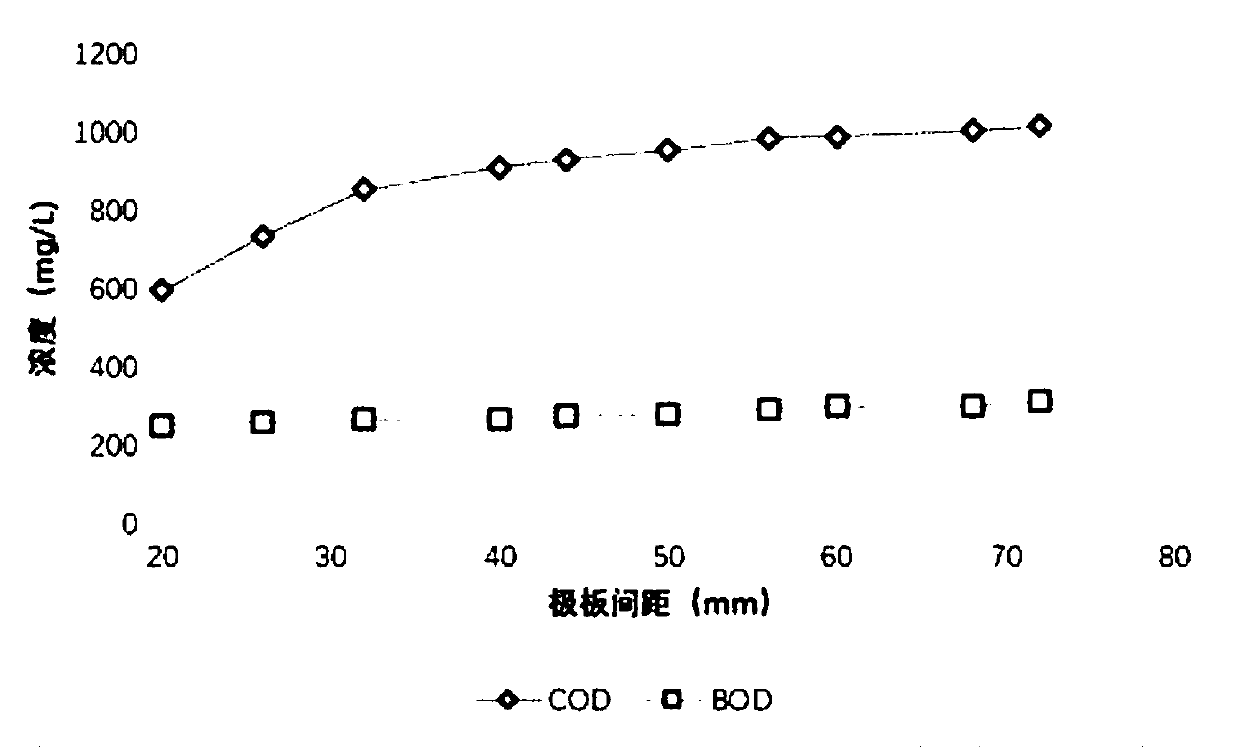

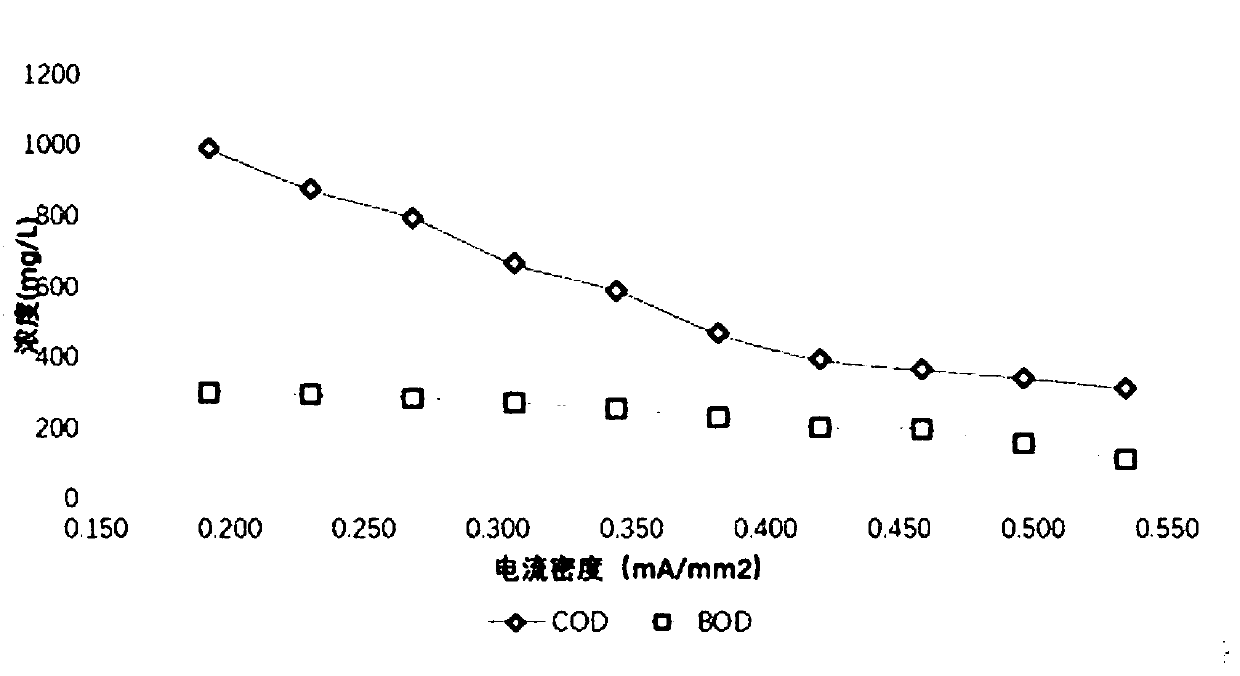

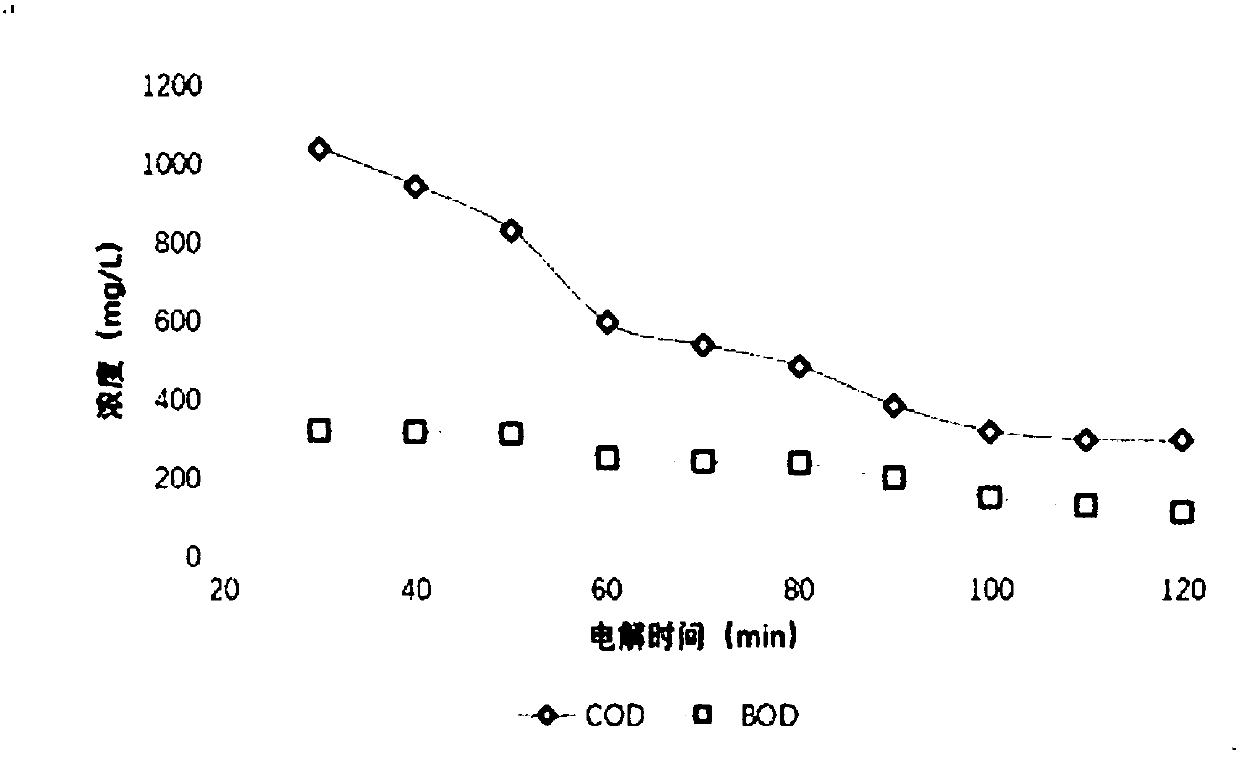

[0025] 3. Electrolysis: introduce the adjusted wastewater into the copper-stainless steel electrode system, apply a DC voltage of 5-60V, and make the applied current density 1A / 5250mm 2 , plate spacing 20mm, electrolysis 60min;

[0026] 4. Precipitation: Precipitate the treated wastewater for more than 30 minutes to obtain relatively clear supernatant and pectin precipita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com