A new type of automatic vacuum packaging machinery

A vacuum packaging and mechanical device technology, applied in packaging, transportation and packaging, packaging/bundling items, etc., can solve problems such as manual operation, inability to automate production and packaging, and inability to automatically replace molds for items of different shapes, to achieve structural Scientific and reasonable, speed up packaging, safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

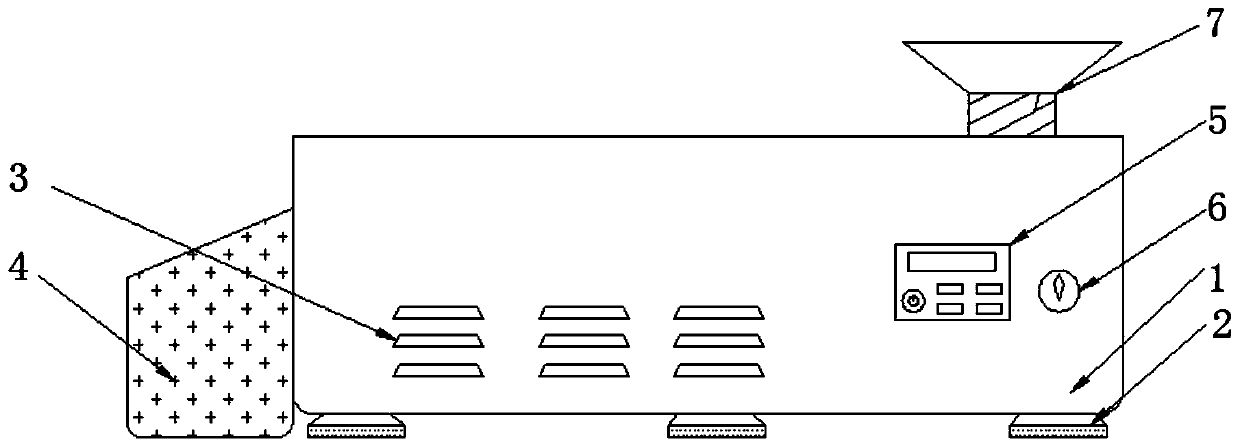

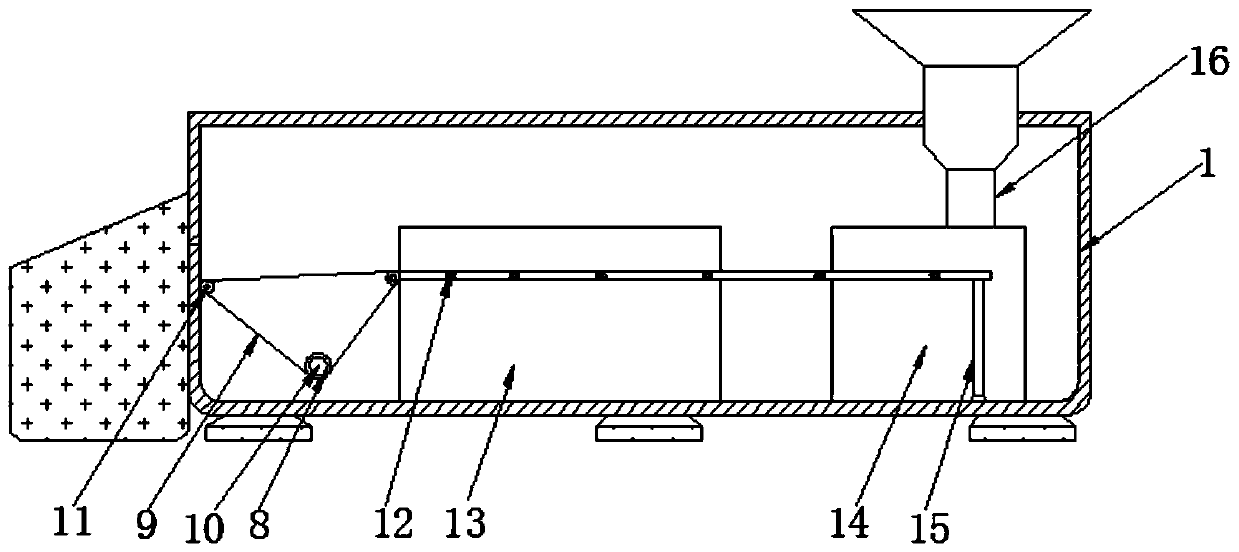

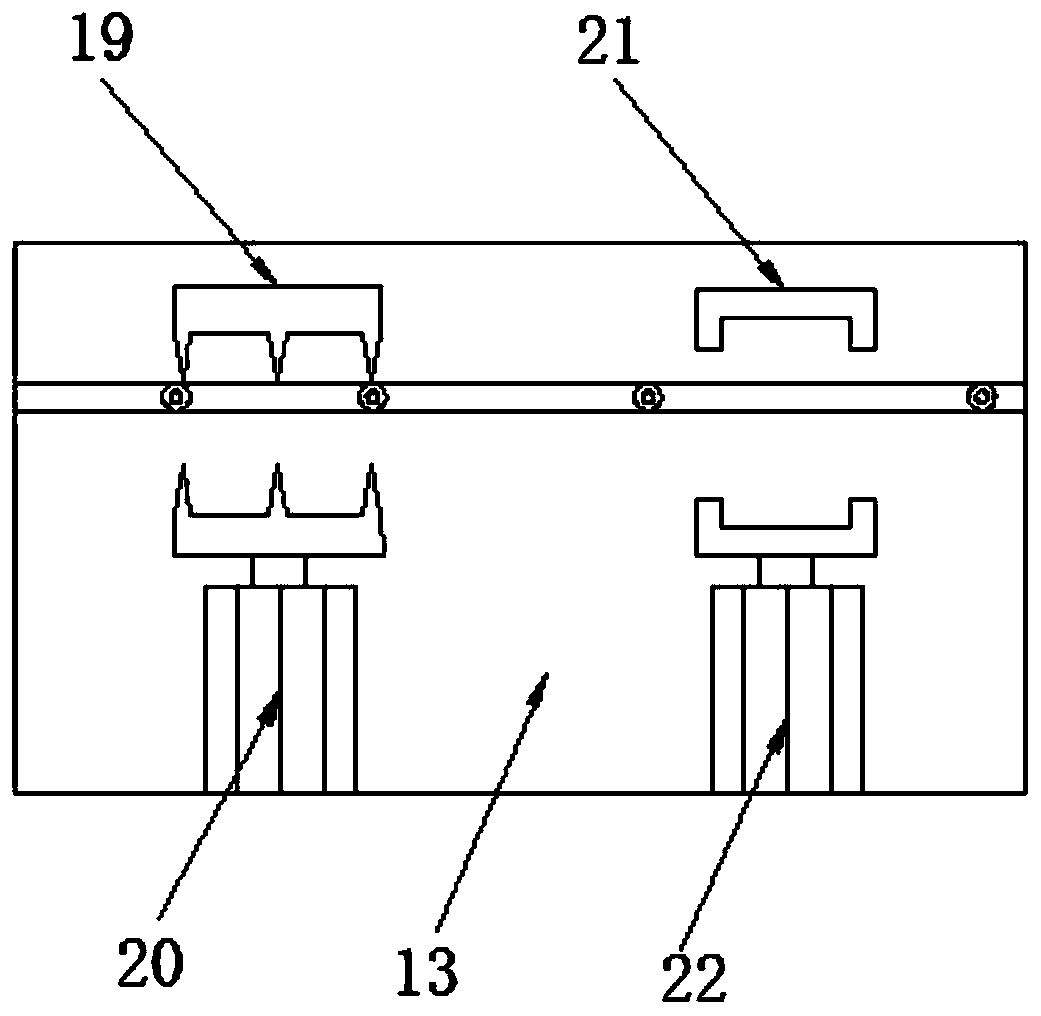

[0026] Example: such as Figure 1-7 As shown, the present invention provides a technical solution, a new type of automatic vacuum packaging mechanical device, including a protective shell 1, a rubber base 2, an air vent 3, a storage box 4, a control switch 5, a negative pressure gauge 6, a hopper 7, Servo motor 8, transmission bar 9, driving wheel 10, driven wheel 11, pulley 12, processing chamber 13, distribution chamber 14, support rod 15, feeding pipe 16, exhaust port 17, drain port 18, notch forming cavity 19 , slit forming device 20, vacuum forming cavity 21, vacuum forming device 22, forming box 23, feeding box 24, upper layer film 25, preheater 26, lower layer film 27, rotating rod 28, clamping device 29 and folding A door 30, a rubber base 2 is installed at the bottom of the protective case 1, and the left part of the protective case 1 is provided with an air vent 3, a control switch 5 is installed on the right side of the air port 3, and a negative pressure gauge 6 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com