Automatic vulcanization line and vulcanization method for tires

A vulcanization line and tire technology, applied in the automatic tire vulcanization line and its vulcanization field, can solve the problems that the fine adjustment of the position and shape of the raw tire cannot be realized, the raw tire cannot be accurately placed in the vulcanization module, and the repeated positioning accuracy of the truss manipulator is low. , to achieve the effect of improving automation level and production efficiency, compact structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

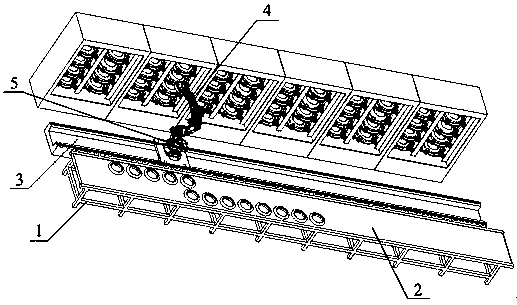

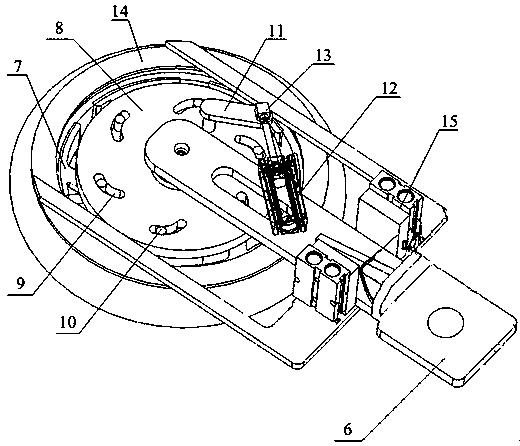

[0022] An automatic tire vulcanization line in this embodiment includes an assembly line, a robot loading and unloading system, and a vulcanizer. The assembly line includes a support device 1 and a conveying device 2 placed on the top of the support device 1. The robot loading and unloading system includes a ground walking track 3 , tire clamping mechanism 4 and robot body 5, the green tire on the transfer device 2 is transferred to the vulcanizing machine by the tire clamping mechanism 4 for green tire vulcanization.

[0023] The assembly line also includes an optical fiber sensor, which is installed on the side wall of the transmission device and fixedly connected with the support device through fixing bolts.

[0024] The longitudinal section of the ground walking track 3 is U-shaped, and a slide rail is arranged on the upper par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com