Method for machining vane of graphite vane pump and special clamp thereof

A processing method and technology of special fixtures, applied in stone processing equipment, manufacturing tools, fine working devices, etc., can solve the problems of low production efficiency and long processing cycle, and achieve the effect of improving processing efficiency and easy to ensure processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the examples and drawings, but the embodiments of the present invention are not limited thereto.

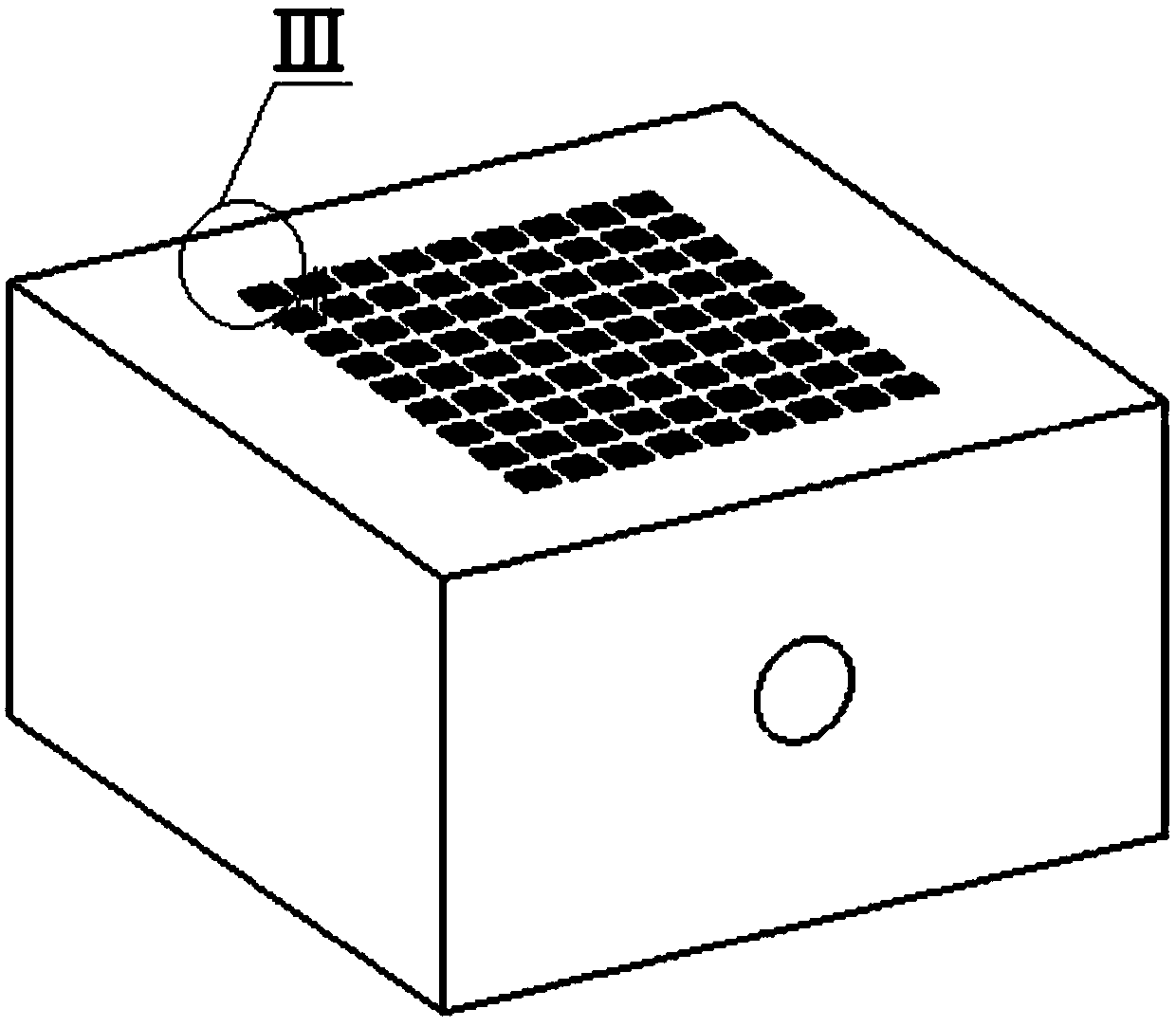

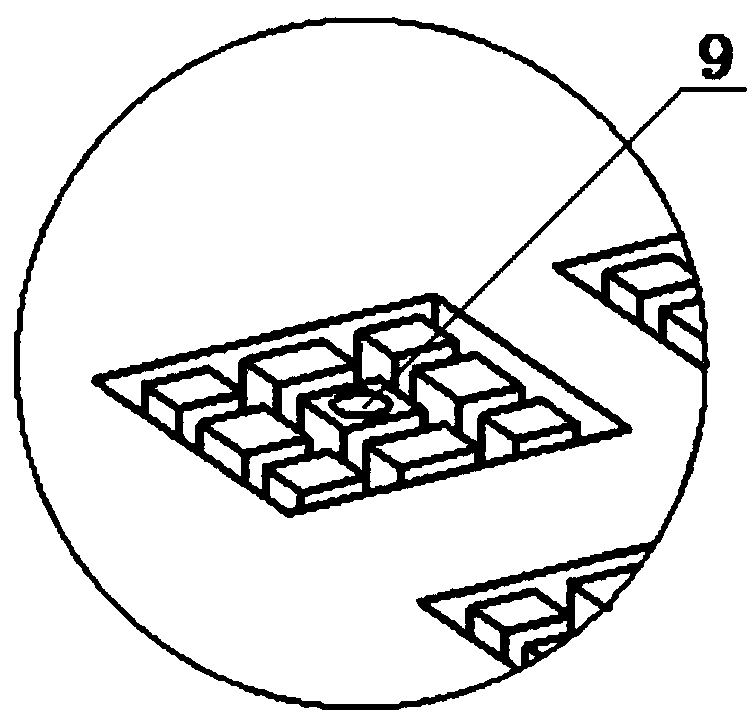

[0043] see Figure 5-Figure 11 , a method for processing a vane pump rotary vane of the present embodiment, comprising the following steps:

[0044] (1) Cutting: Select graphite sheet 1 and cut it according to the specifications.

[0045] (2) End face milling: first carry out rough milling to the first end face of the graphite sheet 1; then turn over the graphite sheet 1, carry out rough milling on the second end face, and then carry out fine milling on the second end face; finally, Turn over the graphite sheet material 1 again, and carry out fine milling processing to the first end face; The two sides of the finished sheet, these two sides are matched with the rotary vane groove in the rotor when used, there is no need to separately process the two sides of the rotary vane in the subsequent proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com