Components for clock movements

一种钟表机芯、外表面的技术,应用在非磁性枢转心轴,叉轴以及擒纵齿轴,摆轴领域,能够解决合金昂贵、高成本、难机加工枢转心轴等问题,达到磁场敏感性低、耐冲击性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In this specification, the term "non-magnetic" refers to a paramagnetic or diamagnetic or antiferromagnetic material with a magnetic permeability lower than or equal to 1.01.

[0030] An alloy of an element is an alloy that includes at least 50% by weight of that element.

[0031] The present invention relates to a component for a timepiece movement, and in particular to a non-magnetic pivoting spindle for a mechanical timepiece movement.

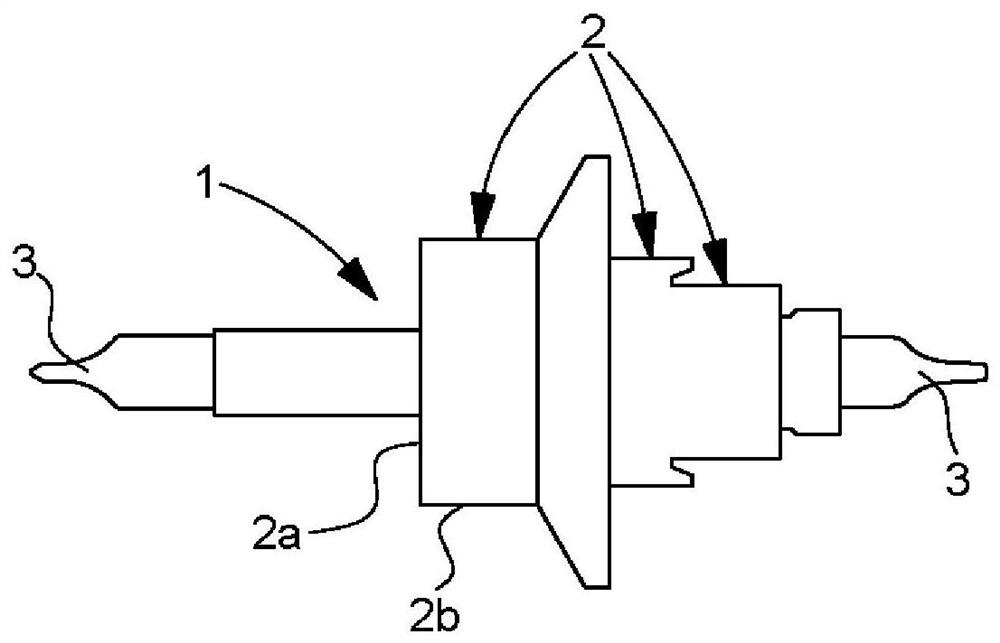

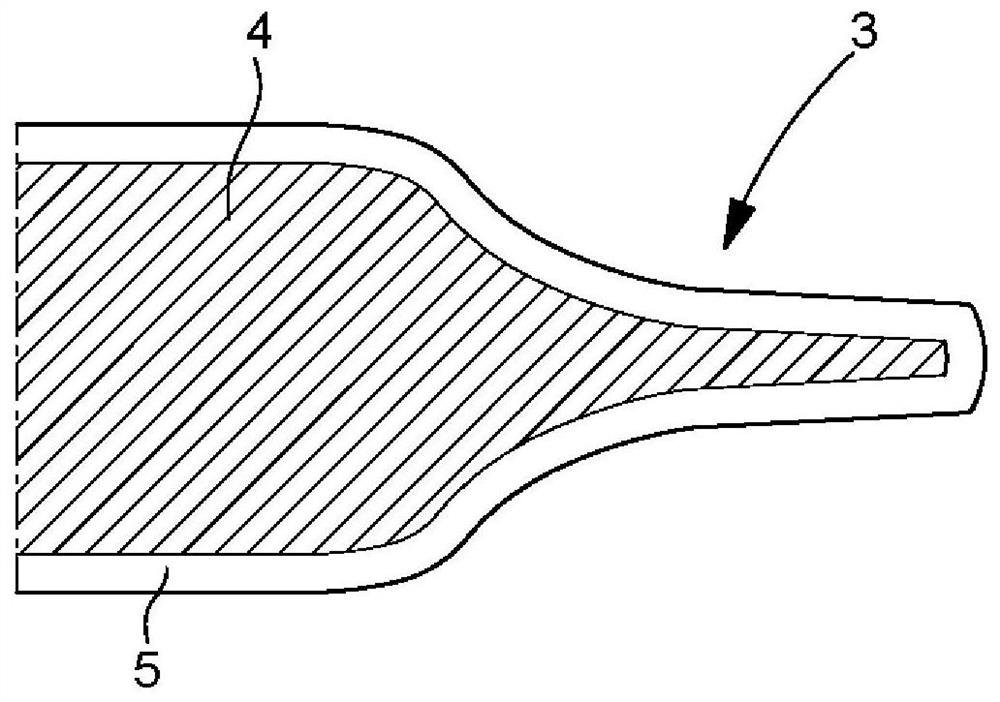

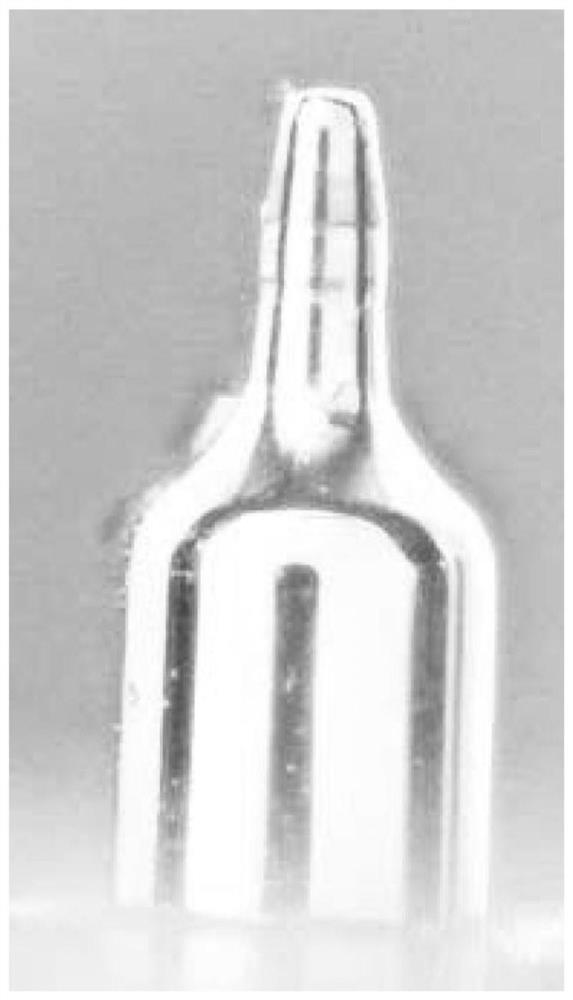

[0032] The present invention will be described below with reference to the application of the non-magnetic pendulum shaft 1 . Of course, other types of timepiece pivoting spindles are also conceivable, such as a timepiece wheel set spindle, typically an escape pinion or a fork. Such a member has a body preferably less than 2 mm in diameter and a pivot preferably less than 0.2 mm in diameter, with a precision of a few microns.

[0033] refer to figure 1 , which shows a pendulum shaft 1 according to the invention comprising a plural...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com