Cut blasting optimal design method under high crustal stress condition

A technology of high in-situ stress and optimized design, applied in blasting and other directions, can solve problems such as the difficulty of deep rock mass cutting and blasting excavation, and achieve the effect of reducing the probability of occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

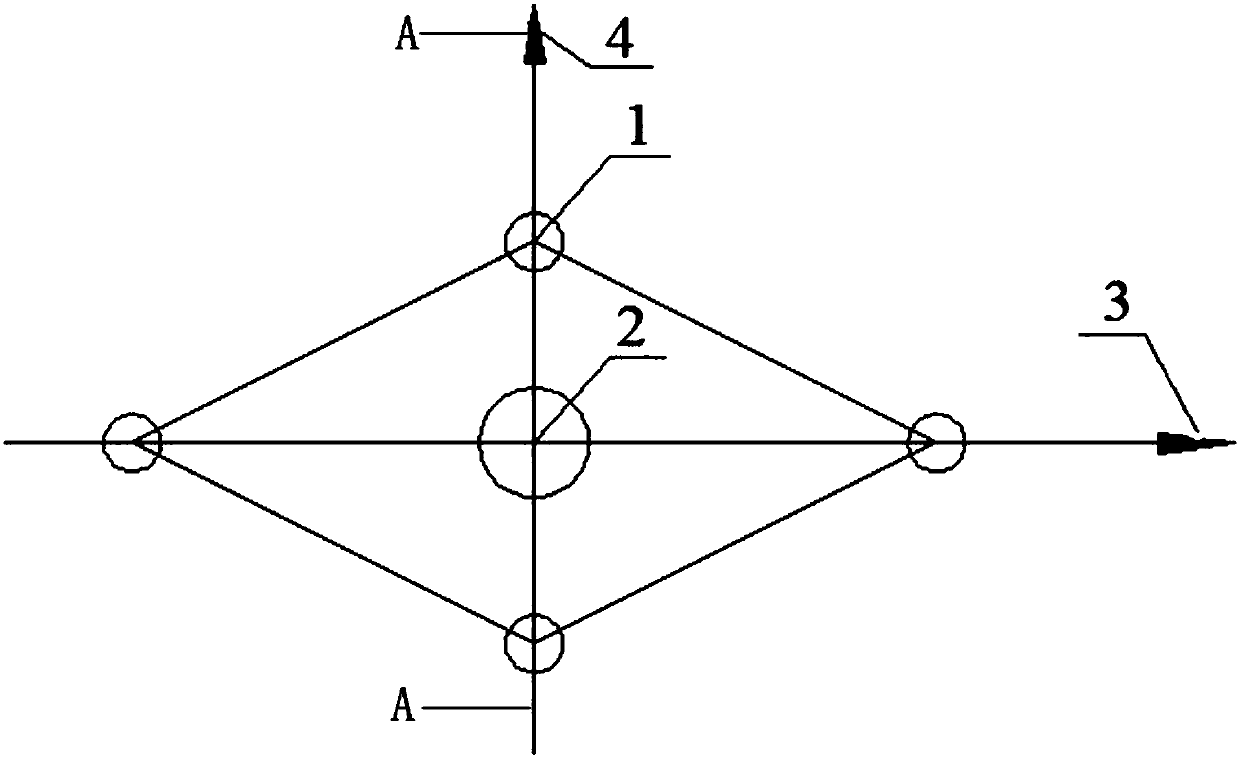

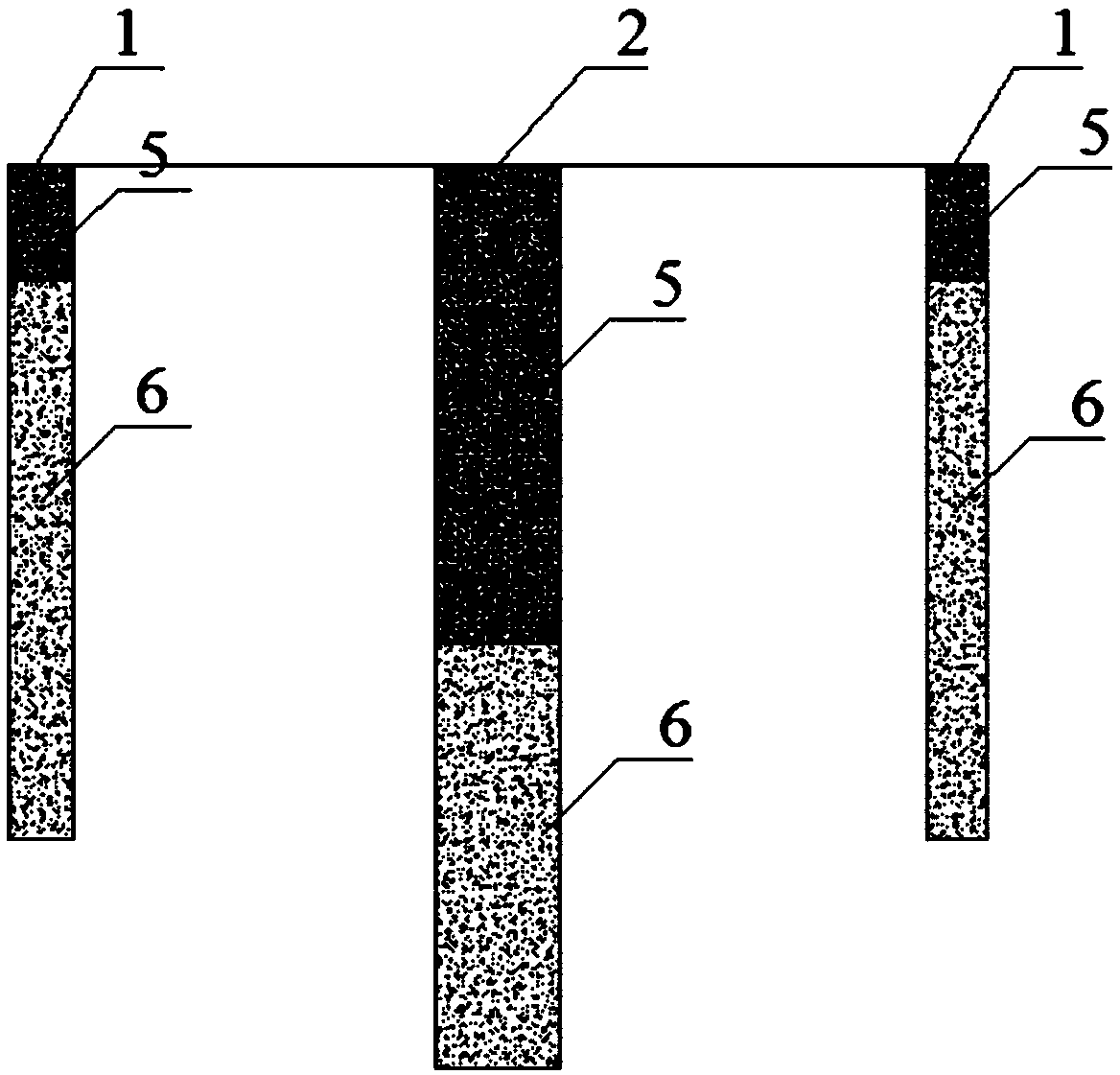

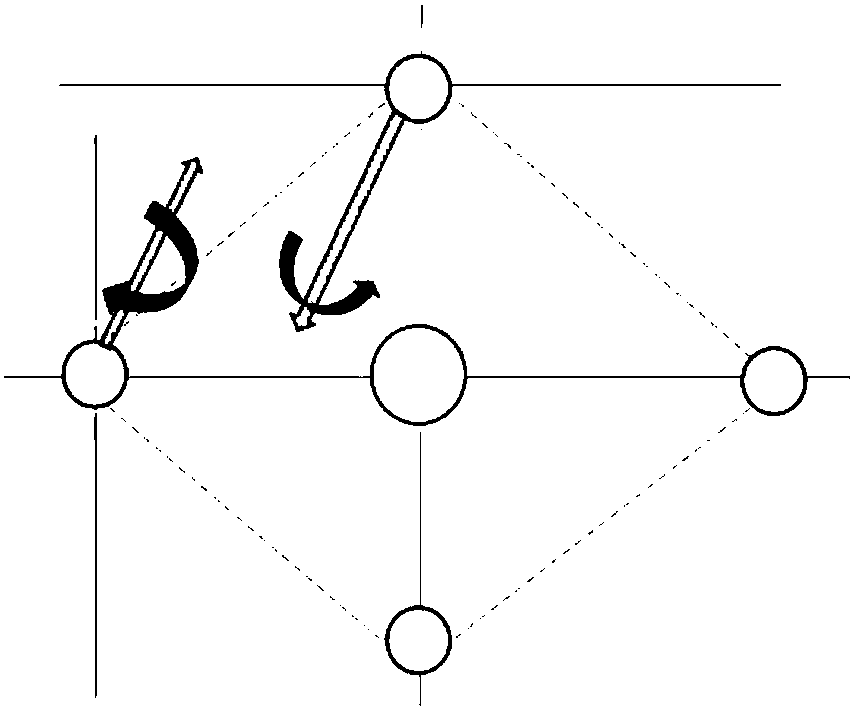

[0022] The present invention will be further described below in conjunction with the drawings. The following embodiments are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

[0023] Deep rock mass needs to be excavated by blasting. Due to the high ground stress during the blasting process, it is difficult to excavate deep rock mass by conventional cut blasting. The high ground stress of deep rock mass and the anisotropy of rock mass destruction are caused It is an important factor in the difficulty of cutting blasting in deep rock masses. In order to make the cutting blasting proceed smoothly, it is necessary to solve this problem.

[0024] In this field, when two blastholes are detonated at the same time, the rock around the blasthole first undergoes compression failure under the action of the shock wave, and then the rock undergoes tensile failure under the action of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com