Water-based metal rust inhibitor

A technology of base metal and rust inhibitor, applied in the directions of additives, petroleum industry, lubricating compositions, etc., can solve the problems of environmental pollution, troublesome treatment, waste of resources, etc., and achieve the effect of high concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

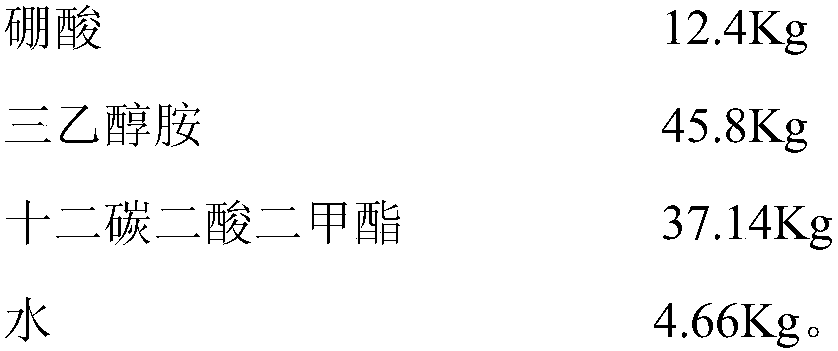

[0021] A water-based metal antirust agent, its raw material components and weight percentages are respectively:

[0022]

[0023] The preparation method of above-mentioned water-based metal antirust agent is:

[0024] Add boric acid, triethanolamine, and dimethyl dodecanoate in sequence to the water, mix well, and let stand for 20 minutes to obtain the product.

Embodiment 2

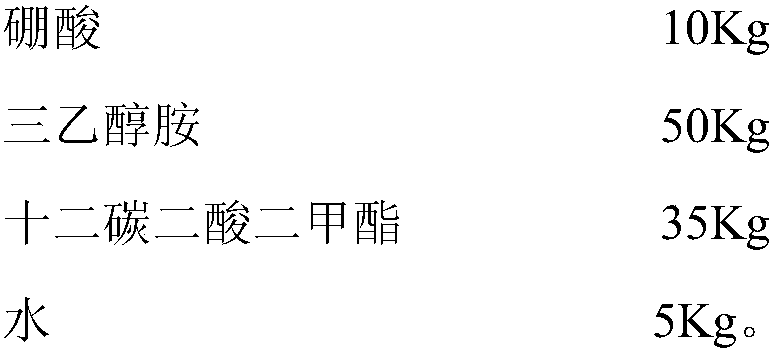

[0026] A water-based metal antirust agent, its raw material components and weight are respectively:

[0027]

[0028] The preparation method of the above-mentioned water-based metal antirust agent is the same as in Example 1.

Embodiment 3

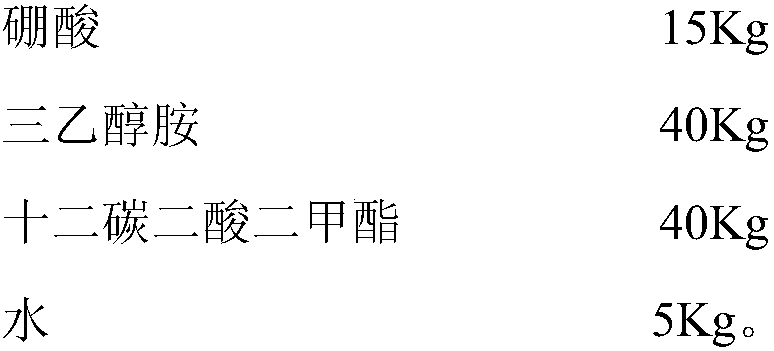

[0030] A water-based metal antirust agent, its raw material components and weight are respectively:

[0031]

[0032] The preparation method of the above-mentioned water-based metal antirust agent is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com