Core-shell quantum dots, preparation method and application thereof

A technology of core-shell quantum dots and quantum dots, which is applied in the field of core-shell quantum dots and its preparation, can solve the problems of poor size and morphology dispersion of core-shell quantum dots, and wide half-peak fluorescence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

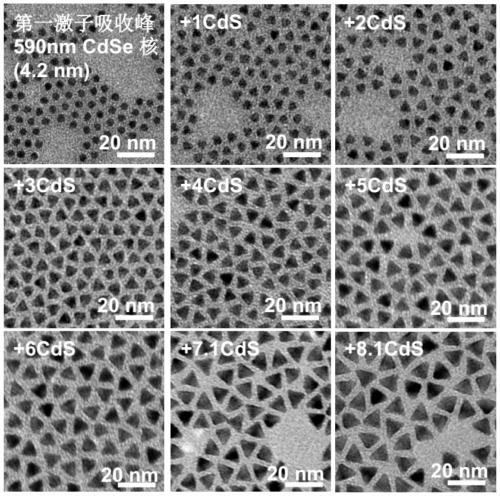

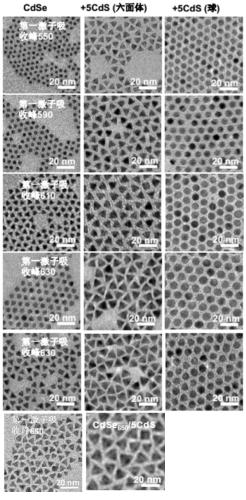

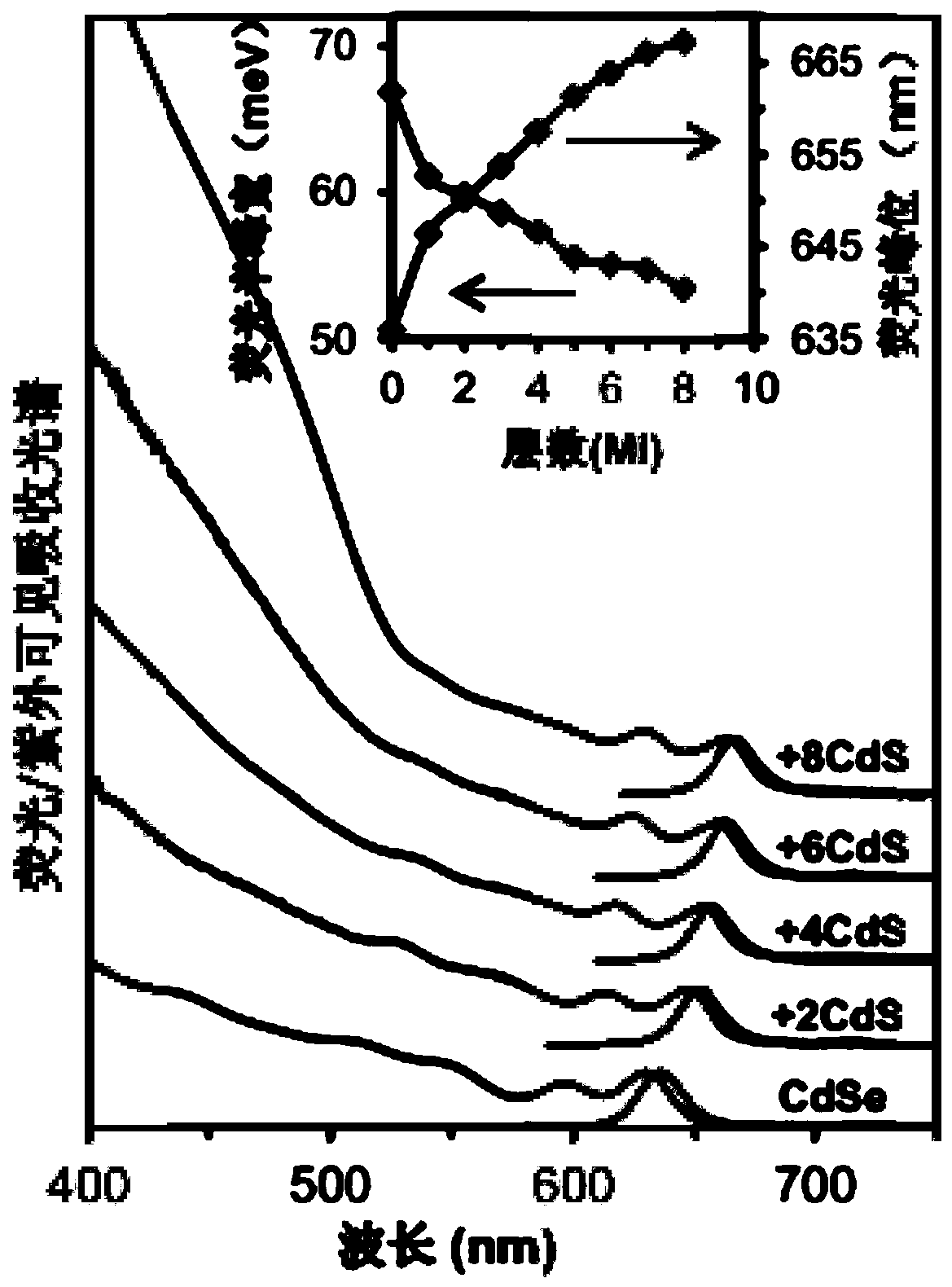

[0058]In a typical embodiment of the present application, a method for preparing core-shell quantum dots is provided, including: step S1, mixing the quantum dot core solution and the second cation precursor solution to form a second system; step S2, When the average diameter of the quantum dot nucleus in the quantum dot nucleus solution is greater than or equal to 2 times the minimum Bohr diameter of holes or electrons of the quantum dot nucleus constituent material, add the second anion to the second system at 210-280°C The precursor solution and the second fatty acid are used for epitaxial growth to obtain core-shell quantum dots, and the second anion precursor solution and the second fatty acid are added in batches to form a second product system; or, when the quantum dots in the quantum dot core solution When the average diameter of the dot core is less than 2 times the minimum Bohr diameter of holes or electrons of the quantum dot core constituent material, the second anio...

Embodiment 1

[0105] Synthesis of spherical CdSe quantum dots (average diameter 3.3nm) with the first exciton absorption peak at 550nm: CdO (0.0256g, 0.2mmol), HSt (stearic acid, 0.1420g, 0.5mmol) and ODE (octadecene , 4mL) into a 25mL three-neck flask, stirred for 10 minutes with argon, then heated up to 280°C to obtain a clear solution, then cooled to 250°C. 1 mL of selenium powder suspension with a concentration of 0.1 mmol / mL was quickly injected into the above-mentioned three-necked flask, and the reaction temperature was controlled at 250°C. After reacting for 7 minutes, quickly inject 0.05 mL of 0.1 mmol / mL selenium powder suspension into the three-necked bottle every 2 to 3 minutes until the size of the quantum dots reaches the target size, and stop heating immediately. During the reaction, the ratio of the total substance amount of the first cation precursor (Cd) to the total substance amount of the first anion precursor (Se) is 1:0.75. During the reaction process, a certain amoun...

Embodiment 2

[0109] Synthesis of spherical CdSe (average diameter 4.2nm) quantum dots with the first exciton absorption peak at 590nm: put CdO (0.0256g, 0.2mmol), tetradecanoic acid (0.1026g, 0.45mmol) and ODE (4mL) into 25mL In the three-necked flask, after stirring and ventilating for 10 minutes, the temperature was raised to 280° C. to obtain a clear solution, and the temperature was controlled at 250° C. Rapidly inject 1 mL of selenium powder suspension with a concentration of 0.05 mmol / mL into the three-neck flask, and control the reaction temperature at 240°C. After reacting for 5 minutes, add 0.1mL selenium powder concentration is 0.1mmol / mL and contain the selenium powder suspension of 1mmol / mL oleic acid with the speed of 0.9mL / h, drip the above-mentioned selenium powder suspension containing 1mmol / mL oleic acid After the cloudy liquid, continue to react for 5 minutes. Then add the above-mentioned selenium powder suspension again, and circulate successively until the size of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com