An adjustable pay-off device for cable production

A pay-off device and adjustable technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve problems such as affecting the operation of insulating jackets, reducing the number of finished cable products, and insufficient tensioning force, and achieve good subsequent processing quality. Smooth follow-up processing and quick and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

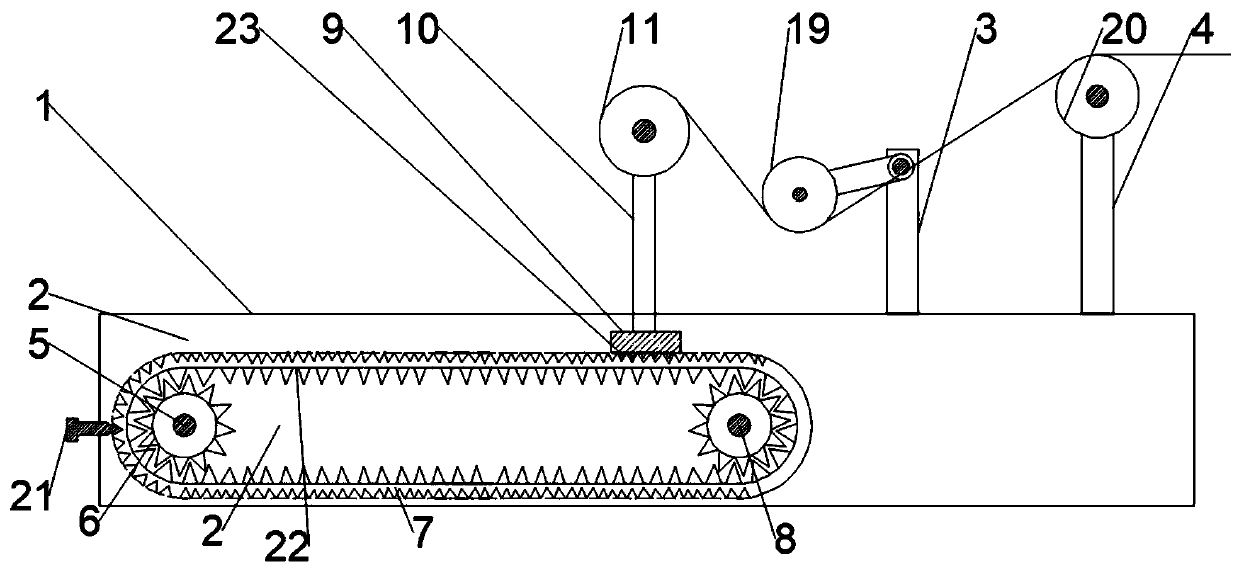

[0027] Such as figure 1 As shown, the present invention provides an adjustable pay-off device for cable production, including a base 1, the left side of the top of the base 1 is provided with a mounting groove 2, and the right side of the top surface of the base 1 is fixedly installed with an adjustment rod 3 and Vertical rod 4, the shape of the base 1 is a cuboid, the adjustment rod 3 is located on the left side of the vertical rod 4, and both the adjustment rod 3 and the vertical rod 4 are perpendicular to the top surface of the base 1, and the adjustment rod 3 is located between the support rod 10 and the vertical rod 4. Between the rods 4, it is better to use the adjustment wheel 19 to adjust the tension of the cable. The end face shape of the installation groove 2 is T-shaped, so that the rectangular block 9 drives the support rod 10 to be displaced more stably, and the pay-off wheel 11 is also stable. It will fall and affect the pay-off operation.

[0028] Such as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com