Processing method of rubber gasbag special for petroleum drilling machine

A technology of rubber airbags and processing methods, applied in applications, household appliances, other household appliances, etc., can solve the problems of not being able to quantify according to needs, increase production costs, consume large amounts of energy, etc. The effect of avoiding waste and saving production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

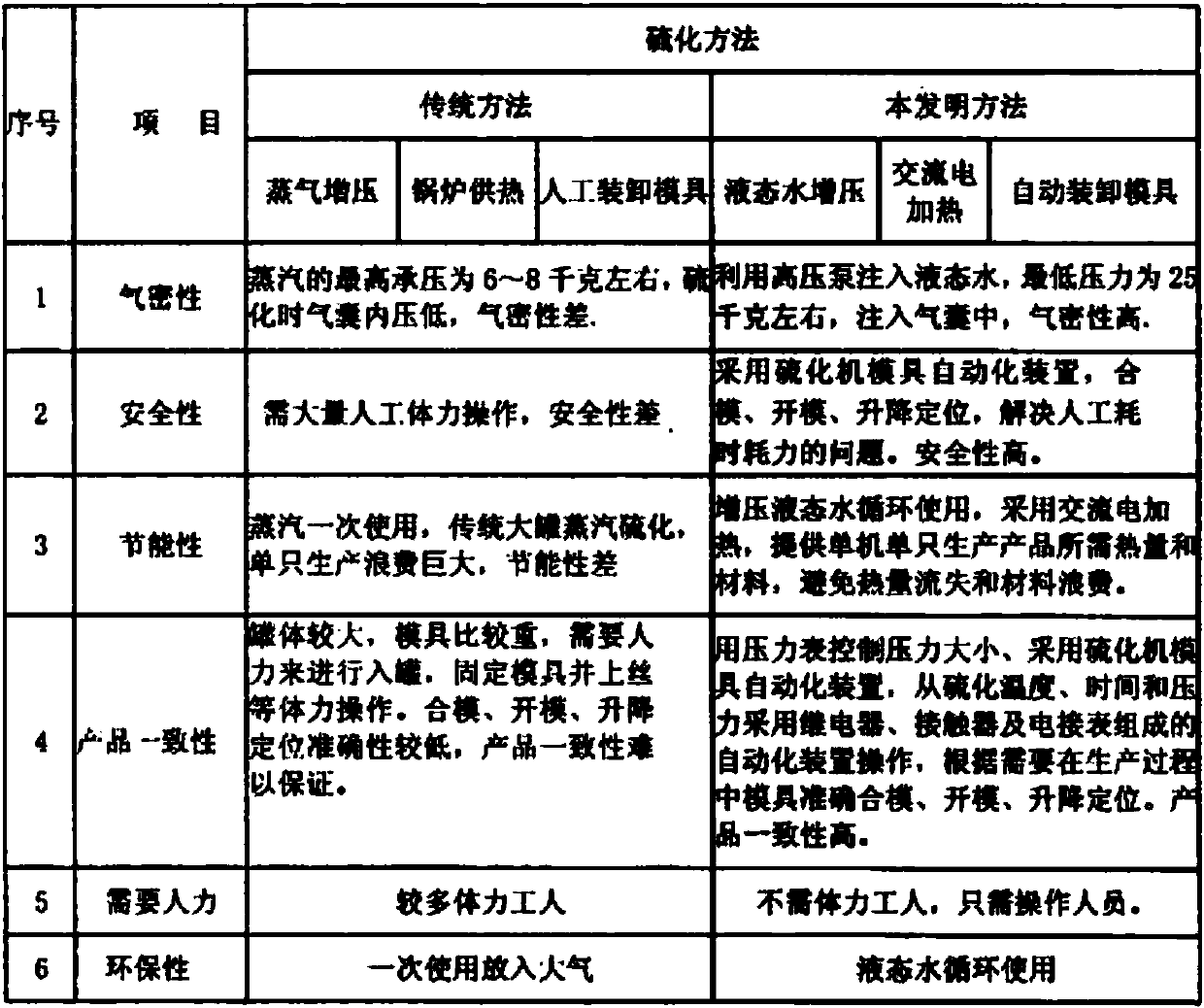

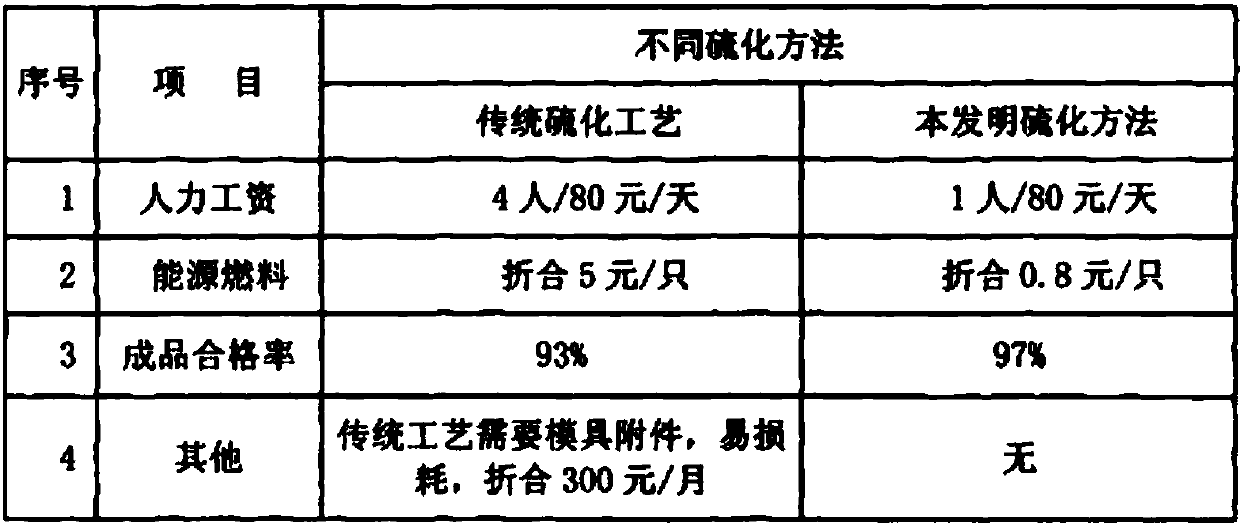

Method used

Image

Examples

Embodiment

[0041] Embodiment: A kind of processing method of special rubber air bag for petroleum drilling rig, comprising six process steps such as rubber mixing, calendering and cutting, extrusion, molding, vulcanization, packaging, etc., its specific processing steps are as follows:

[0042] A. Rubber mixing process:

[0043] ① Ingredients: According to the weight requirements of the production formula, accurately weigh each raw material and place it in the material basin for mixing;

[0044] ②Plastication of raw rubber: Before adding glue, adjust the roller pitch of the mill to 1-1.5mm, adjust the temperature of the rollers to room temperature, and roll the raw rubber materials with different sizes and viscosities in order to soften them, and pass 7 times to form a section. ;Mix all raw rubber materials evenly, then adjust the roller distance of the open mill to 4-5mm, thin pass twice, and pack the obtained plasticized rubber for later use;

[0045] ③Mixing: Put the plasticized rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com