Luneberg lens design method based on 3D printing technology

A Longbo lens and 3D printing technology, applied in computing, antenna, application and other directions, can solve the problems of lengthy production process and high production cost, achieve broad market prospects, high printing accuracy, and ensure product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

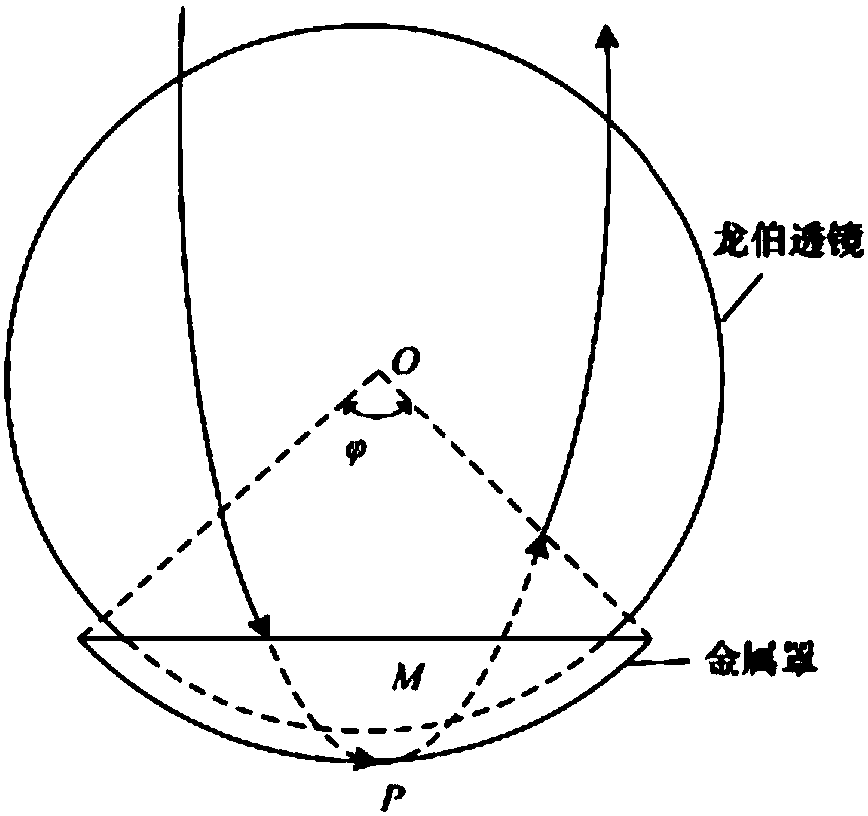

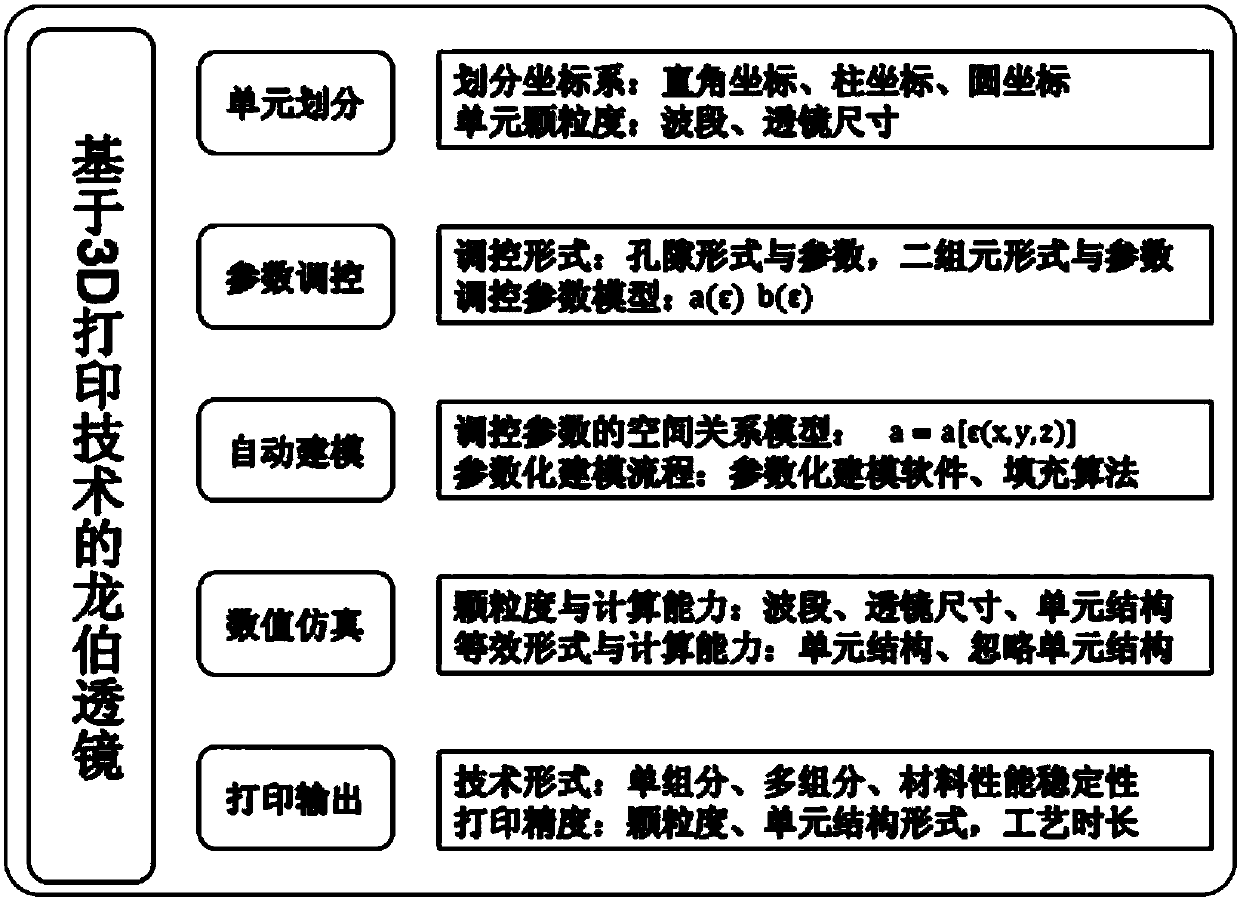

[0038] The present invention overcomes the deficiencies of the prior art, and provides a design method for Lunberg lenses based on 3D printing technology, which can realize rapid design and rapid prototyping of Lunberg scatterers with specific frequency points and specific RCS indicators compared with the prior art , which effectively improves the design level of electromagnetic target characteristics and the level of process realization, and has good practical value. The method of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0039] The invention does not require mechanical processing and moulds, and directly generates parts of any shape required from computer graphics data. The cost is 1 / 4 of the traditional layered structure, and the processing time is only a few hours. The rapid realization of specified RCS parameters can be completed. The specific scheme is as follows, the whole Lunberg lens is divided into several...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com